Главная

There are 188 products.

Used MURAT KC258, 2017. Twin-Head Welding Machine

MURAT KC258, 2017

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

$0.00

Used MURAT KT-804 Sash Hardware Assembly Table

MURAT KT-804 HARDWARE ASSEMBLY STATION

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

$0.00

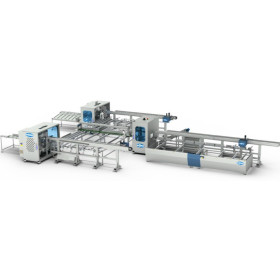

Used Haffner NR-242 Cutting&Milling Machining Center UPVC

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

$0.00

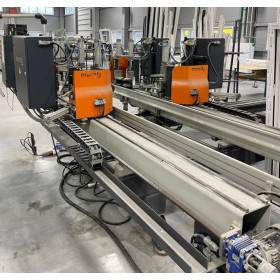

Used MURAT KD658/20 CNC 4-HEAD Welding Machine

KD658/20 4-Head Horizontal Welding Machine, 2019

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

$0.00

Dezhong LLWYJ-20 Automatic 20T 3Axis Bending Machine (Siemens control system)

Automatic 20T 3Axis Bending Machine (Siemens control system)

Model - LLWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 330mm-530mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1000*800*1600mm

Weight of machine 800kg

Model - LLWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 330mm-530mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1000*800*1600mm

Weight of machine 800kg

$17,500.00

Dezhong LWYJ-20 Automatic 20T Bending Machine (Siemens control system)

Automatic 20T 3Axis Bending Machine (Siemens control system)

Model - LWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

Model - LWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

$17,500.00

Dezhong LWYJ-CNC-20 Automatic 20T CNC Bending Machine (Industrial control system)

Automatic CNC Roll Bending Machine (Industrial computer system)

Model - LWYJ-CNC-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-dimensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-15r/min

Y-roller cylinder positioning accuracy ±0.02mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

Model - LWYJ-CNC-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-dimensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-15r/min

Y-roller cylinder positioning accuracy ±0.02mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

$39,000.00

Dezhong LSWYJ-20 Automatic 20T Bending Machine (UPVC + ALU))

Automatic 20T 3Axis Bending Machine (Siemens control system)

Equipped by 3 pc of Heating Gun for UPVC processing

Model - LSWYJ-20T

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

Equipped by 3 pc of Heating Gun for UPVC processing

Model - LSWYJ-20T

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

$21,000.00