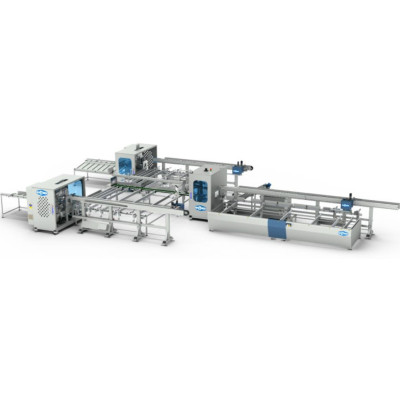

Used Haffner NR-242 Cutting&Milling Machining Center UPVC

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Delivery throughout Russia - by transport company.

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

The concept of this center involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Features

• The NR 242 machining center performs all sawing, milling, and marking operations on PVC profiles, as well as screwing PVC profiles to steel reinforcement and machining already reinforced workpieces (drilling three holes for a handle, drilling for a mullion, etc.); the process is computer-controlled.

• Loading station for up to 10 profiles (up to 6.5 m long)

• Automatic sawing of workpieces with a servo-driven saw at angles from 30° to 150° with an accuracy of 0.1°; cutting is performed with a 500 mm diameter saw blade.

• Two stations for processing sawn profiles with installed reinforcing steel profiles

• Automatic conveyor for collecting profile scraps

• Two barcode printers for labeling processed and sawn blanks (labels are applied manually)

• 19-inch touchscreen monitor.

• Windows-based computer, adapted for operation at temperatures of 0-55 degrees Celsius without additional cooling.

• Central lubrication system for easy machine maintenance.

• Remote service via the internet.

Supplied operations:

Cutting at angles from 30° to 150°

Manage holes and lock grooves

Marking for mounting plates, hinges, door hinges, and threshold trims.

Milling the end of the mullion

Machining for a door profile cylinder

Machining for a lock lock

Marking for hardware

Drilling 3 holes for a handle in the PVC profile and reinforcement

Drilling holes for installing mullions in the PVC profile and reinforcement

Automatic screwing of reinforcement to the PVC.

Printers for manual labeling of blanks

The center is sold by bank transfer with VAT. An official supply contract is concluded.

Under a separate contract excluding VAT, we provide commissioning, installation, dismantling, and training. We can arrange delivery and transportation throughout the Russian Federation.

The price is below market value; the promotion is valid until the end of 2025. Please inquire about the price in a message or write to Nikolay on WhatsApp or Telegram to the direct number +79276015645. We respond quickly.

The equipment is connected and in working order.