FENSTEK & SINON, CHINA (UPVC & ALUM MACHINES)

There are 50 products.

FENSTEK CMC-4-2500 CNC Copy Router Machine 3+1 Axis. Windows

FENSTEK CMC-4-2500 CNC COPY MILLING MACHINE 2500 MM, SERVO DRIVE

CMC4-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. CMC3-2500 aluminum window making machine is an advanced industrial CNC profile processing system - 3+1 axis. The rotary table is equipped with servo motor.

2. Suitable for processing aluminum, PVC and other light metals;

3. The machine can complete milling, drilling, tapping, chamfering, grooving and other multi-functional operations precisely at one time.

4. The working table can be set at any angle from +90° to -90°. The rotary table is driven by servo motor.

CMC4-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. CMC3-2500 aluminum window making machine is an advanced industrial CNC profile processing system - 3+1 axis. The rotary table is equipped with servo motor.

2. Suitable for processing aluminum, PVC and other light metals;

3. The machine can complete milling, drilling, tapping, chamfering, grooving and other multi-functional operations precisely at one time.

4. The working table can be set at any angle from +90° to -90°. The rotary table is driven by servo motor.

$42,800.00

FENSTEK CMC-3-2500 CNC Copy Router Machine, 3-Axis. PLC LINUX

FENSTEK CMC-3-2500 CNC COPY MILLING MACHINE 2500 MM

CMC3-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

CMC3-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

$32,350.00

FENSTEK CMC-4-1200 CNC Copy Router 3+1 Axis. Windows

FENSTEK CMC-4-1200 CNC COPY MILLING MACHINE 1200 MM, SERVO DRIVE

CMC4-1200 CNC Copy-Milling Machine for Aluminum Windows Features:

1. Advanced profile processing system 3+1 processing axis

2. Processing range 120 x 120 mm 3. Tool travel length along guides – 1200 mm

3. Possibility to increase maximum length to 2500 mm on CMC4-2500 model

4. Work table with servo positioning -90 ° / 0 ° / + 90 ° / 45 ° or the ability to set non-standard angles upon request.

CMC4-1200 CNC Copy-Milling Machine for Aluminum Windows Features:

1. Advanced profile processing system 3+1 processing axis

2. Processing range 120 x 120 mm 3. Tool travel length along guides – 1200 mm

3. Possibility to increase maximum length to 2500 mm on CMC4-2500 model

4. Work table with servo positioning -90 ° / 0 ° / + 90 ° / 45 ° or the ability to set non-standard angles upon request.

$25,600.00

FENSTEK CMC-3-1200 Copy Router CNC Machine, 3-Axis, LINUX PLC

CMC3-1200 Aluminum Window CNC Copy Routing Machine

Features:

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

5. Adopts high precision ball screws to ensure smooth motion, positioning and processing in high precision.

6. The operating platform of the system: Linux platform.English, Chinese, Thai, Korean and Vietnamese language are available.

7. The latest version of the system: 4-core 4G memory, fast & smooth operation.

8. Additional one meter Support table for special long profile processing.

9.400mm height safety cover for safety operation.

Features:

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

5. Adopts high precision ball screws to ensure smooth motion, positioning and processing in high precision.

6. The operating platform of the system: Linux platform.English, Chinese, Thai, Korean and Vietnamese language are available.

7. The latest version of the system: 4-core 4G memory, fast & smooth operation.

8. Additional one meter Support table for special long profile processing.

9.400mm height safety cover for safety operation.

$23,200.00

FENSTEK CMC-3-2500 CNC Copy Router Machine, 3+1Axis. Delta Windows

FENSTEK CMC-3-2500 CNC COPY MILLING MACHINE 2500 MM

CMC3-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

CMC3-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

$37,000.00

FENSTEK DACC120A Double CNC Corner Cleaning Station

DACC120A CNC Double Head Corner Cleaner

Features:

1. Cleaning of welding angle seam for plastic doors and windows

2. Two CNC machine head transport, one-time completion of rectangular frame (fan) two angles cleaning, more efficient.

3. Can complete all kinds of profile facade, upper and lower plane weld, inner angle slope, inner right angle, inner groove and other functions.

4. Adopt spindle motor, high precision.

5. The machine head feed adopts the high precision square rail motion pair, effectively guarantees the machine precision.

6. Single head teaching, you can complete the four-corner program programming, simple and convenient.

7. Based on the industrial control computer platform, the program is specially developed according to the door and window industry; the whole Chinese operation interface is simple and intuitive; the interface is reserved for the enterprise to realize the information management.

Features:

1. Cleaning of welding angle seam for plastic doors and windows

2. Two CNC machine head transport, one-time completion of rectangular frame (fan) two angles cleaning, more efficient.

3. Can complete all kinds of profile facade, upper and lower plane weld, inner angle slope, inner right angle, inner groove and other functions.

4. Adopt spindle motor, high precision.

5. The machine head feed adopts the high precision square rail motion pair, effectively guarantees the machine precision.

6. Single head teaching, you can complete the four-corner program programming, simple and convenient.

7. Based on the industrial control computer platform, the program is specially developed according to the door and window industry; the whole Chinese operation interface is simple and intuitive; the interface is reserved for the enterprise to realize the information management.

$89,000.00

FENSTEK ACC120F CNC Corner Cleaning Machine, 4-Axis

ACC120F Four Axis CNC Corner Cleaner

Features:

1.Most stable welcomed mature CNC corner cleaning machine.

2.Totally 8 cutters(two pieces of vertical milling cutters, two pieces of pulling cutters, one piece of saw blade,two pieces of hooking blade,one piece of horizontal milling blade) will be automatically cleaning surface, vertical ,horizontal and inside rubber gasket groove,inner part corner. No need tool change.

3.Advanced IPC controlled full machinery automatically precise running.

4.The milling cutters are controlled by spindle motor, much more stable, they are in the CNC axis, very easy to adjust.

5.Diagonal and arc difference compensation function.

6.Four axis moved by ball screw shaft.

7.Within 25 seconds finish one corner complete cleaning.

Features:

1.Most stable welcomed mature CNC corner cleaning machine.

2.Totally 8 cutters(two pieces of vertical milling cutters, two pieces of pulling cutters, one piece of saw blade,two pieces of hooking blade,one piece of horizontal milling blade) will be automatically cleaning surface, vertical ,horizontal and inside rubber gasket groove,inner part corner. No need tool change.

3.Advanced IPC controlled full machinery automatically precise running.

4.The milling cutters are controlled by spindle motor, much more stable, they are in the CNC axis, very easy to adjust.

5.Diagonal and arc difference compensation function.

6.Four axis moved by ball screw shaft.

7.Within 25 seconds finish one corner complete cleaning.

$41,000.00

FENSTEK ACC120A CNC Corner Cleaning Machine, 2-Axis

ACC120A CNC Corner Cleaner For PVC Window Processing, 2-Axis

Feature:

1. Most stable welcomed mature CNC corner cleaning machine for pvc window processing.

2. Totally 5 cutters(two pieces of vertical milling cutters, two pieces of pulling cutters, one piece of saw blade) will be automatically cleaning surface, vertical and inside rubber gasket groove. No need tool change.

3. The milling cutters are controlled by spindle motor, much more stable, they are in the CNC axis, very easy to adjust.

4. Two axis moved by ball screw shaft.

5. Within 25 seconds finish one corner complete cleaning.

6. Can be linked with horizontal welding machine to become welding & corner cleaning production line for grand imagine and high efficiency.

7. Friendly operation. Quick learning.

8. Optional: one piece of horizontal milling cutter, used for sliding window.

Feature:

1. Most stable welcomed mature CNC corner cleaning machine for pvc window processing.

2. Totally 5 cutters(two pieces of vertical milling cutters, two pieces of pulling cutters, one piece of saw blade) will be automatically cleaning surface, vertical and inside rubber gasket groove. No need tool change.

3. The milling cutters are controlled by spindle motor, much more stable, they are in the CNC axis, very easy to adjust.

4. Two axis moved by ball screw shaft.

5. Within 25 seconds finish one corner complete cleaning.

6. Can be linked with horizontal welding machine to become welding & corner cleaning production line for grand imagine and high efficiency.

7. Friendly operation. Quick learning.

8. Optional: one piece of horizontal milling cutter, used for sliding window.

$29,000.00

FENSTEK CMC-3-3000 QTC / CNC Copy Router Machine, 3+1Axis. Delta Windows

FENSTEK CMC-3-3000 QTC CNC COPY MILLING MACHINE 3000 MM

CMC3-3000 QTC CNC Copy Milling Machine for Aluminum Windows and Doors

QUICK-RELEASE DEVICE FOR INSTANT TOOL REPLACEMENT, INCLUDES THREE TOOL HOLDERS.

AUTOMATIC ROLLER FOR TWO PROCESSING ZONES, UNINTERRUPTIBLE POWER SUPPLY, VOLTAGE STABILIZER.

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

CMC3-3000 QTC CNC Copy Milling Machine for Aluminum Windows and Doors

QUICK-RELEASE DEVICE FOR INSTANT TOOL REPLACEMENT, INCLUDES THREE TOOL HOLDERS.

AUTOMATIC ROLLER FOR TWO PROCESSING ZONES, UNINTERRUPTIBLE POWER SUPPLY, VOLTAGE STABILIZER.

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

$49,700.00

FENSTEK CMC-3-2500 QTC / CNC Copy Router Machine, 3+1Axis. Delta Windows

FENSTEK CMC-3-2500 CNC COPY MILLING MACHINE 2500 MM

CMC3-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

CMC3-2500 CNC Copy Milling Machine for Aluminum Windows and Doors

1. Advanced industrial CNC 3-axis profile machining systems.

2. Suitable for Aluminum, PVC, and other light metal material processing;

3.The machine completes milling, drilling, grooving and other multi-functional precisely in one time.

4. Worktable with pneumatic positioning -90°/0°/+90° .Optional 45 degree milling function is available.

$42,800.00

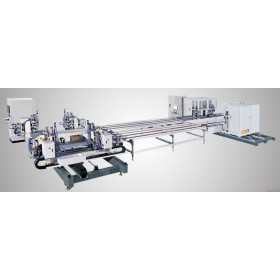

FENSTEK AWCL-2 Welding & Corner Cleaning Line UPVC

AWCL-2

UPVC Window Automatic Welding/Cleaning Production Line(Single Layer)

Whole Machine1. Used for automatically realizing the welding and cleaning of frame or sash, composed of welding unit, transfer unit and corner cleaning unit, etc.2. 2mm seam welding.3. Imported computer control system, with high reliability.4. Production ability between main units matched each other.5. Automatically program and select processing programs.6. Apply to high grade and mass windows production.

$157,600.00

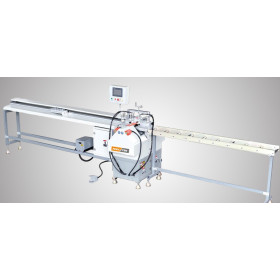

FENSTEK C-3 Cutting & Milling CNC Center UPVC

CUTTING & MILLING CENTER for PVC profiles FABCUT-550. New equipment, made to order from China. High productivity, accuracy and reliability. Delivery time 5-6 months, warranty, installation, service, Russian and English interface.

PRODUCTION FENSTEK, CHINA

Productivity up to 250 standard windows per shift of 8 hours.

PRODUCTION FENSTEK, CHINA

Productivity up to 250 standard windows per shift of 8 hours.

$175,000.00

FENSTEK F-3 Laser Cutting&Milling Center ALU

FENSTEK F-3

CNC Milling and Cutting Processing Center Integrated with Double Laser Head

Features:

1. CNC laser cutting and milling processing center applied in aluminum industry for higher efficiency and good milling result.

2. Powerful function: 550 single saw blade milling machine: -45°~45° arbitrary angle cutting, 3KW high power + mirror cutting.

3. High-speed dual laser: rear laser cutting and front laser line marking, especially the marking of the connecting point of the mullion.

4. Laser processing: rear laser cutting, the power can be adjusted automatically, good cutting quality. Laser processing can be completed on both sides at the same time, accurate positioning and high efficiency.

5. High-speed 4-side milling: Simultaneous milling of front and back on four sides, higher processing efficiency.

CNC Milling and Cutting Processing Center Integrated with Double Laser Head

Features:

1. CNC laser cutting and milling processing center applied in aluminum industry for higher efficiency and good milling result.

2. Powerful function: 550 single saw blade milling machine: -45°~45° arbitrary angle cutting, 3KW high power + mirror cutting.

3. High-speed dual laser: rear laser cutting and front laser line marking, especially the marking of the connecting point of the mullion.

4. Laser processing: rear laser cutting, the power can be adjusted automatically, good cutting quality. Laser processing can be completed on both sides at the same time, accurate positioning and high efficiency.

5. High-speed 4-side milling: Simultaneous milling of front and back on four sides, higher processing efficiency.

$345,000.00

FENSTEK ACC120A (inner bevel) CNC Corner Cleaning Machine, 2-Axis

ACC120A-IB CNC Corner Cleaner For PVC Window Processing, 2-Axis

INCLUDING INNER BEVEL CLEANING

Feature:

1. Most stable welcomed mature CNC corner cleaning machine for pvc window processing.

2. Totally 5 cutters(two pieces of vertical milling cutters, two pieces of pulling cutters, one piece of saw blade) will be automatically cleaning surface, vertical and inside rubber gasket groove. No need tool change.

3. The milling cutters are controlled by spindle motor, much more stable, they are in the CNC axis, very easy to adjust.

4. Two axis moved by ball screw shaft.

5. Within 25 seconds finish one corner complete cleaning.

6. Can be linked with horizontal welding machine to become welding & corner cleaning production line for grand imagine and high efficiency.

7. Friendly operation. Quick learning.

8. Optional: one piece of horizontal milling cutter, used for sliding window.

INCLUDING INNER BEVEL CLEANING

Feature:

1. Most stable welcomed mature CNC corner cleaning machine for pvc window processing.

2. Totally 5 cutters(two pieces of vertical milling cutters, two pieces of pulling cutters, one piece of saw blade) will be automatically cleaning surface, vertical and inside rubber gasket groove. No need tool change.

3. The milling cutters are controlled by spindle motor, much more stable, they are in the CNC axis, very easy to adjust.

4. Two axis moved by ball screw shaft.

5. Within 25 seconds finish one corner complete cleaning.

6. Can be linked with horizontal welding machine to become welding & corner cleaning production line for grand imagine and high efficiency.

7. Friendly operation. Quick learning.

8. Optional: one piece of horizontal milling cutter, used for sliding window.

$32,500.00

FENSTEK LJMJA-CNC-500 Automatic Corner Key Cutting Machine

LJMJA-CNC-500

Aluminum Window Automatic Corner Key Cutting Saw

Features:

1. This CNC corner key cutting saw mainly for high volume cutting of aluminium profile ofindustrial application

2. Large cutting capacity for wide profile or several working piece cutting

3. with support of cutting jig to accommodate profile shape.

4. Auto setting cutting length.

5. PLC , servo motor and ball screw assure easy and precise setting and cutting

6. Adjustable parameter for saw blade feeding to improve production efficiency.

7. Vertical and horizontal clamping assure precision.

8. Hydraulic and pneumatic cylinder assure smooth cutting surface

9. Special collected box receive corner key.

Aluminum Window Automatic Corner Key Cutting Saw

Features:

1. This CNC corner key cutting saw mainly for high volume cutting of aluminium profile ofindustrial application

2. Large cutting capacity for wide profile or several working piece cutting

3. with support of cutting jig to accommodate profile shape.

4. Auto setting cutting length.

5. PLC , servo motor and ball screw assure easy and precise setting and cutting

6. Adjustable parameter for saw blade feeding to improve production efficiency.

7. Vertical and horizontal clamping assure precision.

8. Hydraulic and pneumatic cylinder assure smooth cutting surface

9. Special collected box receive corner key.

$26,600.00

FENSTEK AGBS3000 Automatic Glass Bead Cutting Machine

FENSTEK AGBS3000 Automatic Glass Bead Cutting Machine

UPVC Window CNC Glazing Bead Saw

Features:

1.Automatic 45 degree cutting u-PVC glazing bead profile.

2.Two glazing bead cutting in one time.

3.Automatic saw blade feeding by pneumatic cylinder and moving on precise rod.

4.4 pieces saw blade ensure precise cutting, Double cutting one each end to mill the hook foot.

5.Vertical clamping device and special designed cutting jig ensure stable positioning.

6.Two hand safety operation

7.Friendly using measuring rod.

8.Precise & easy operated measuring table (Only for GBST1800)

UPVC Window CNC Glazing Bead Saw

Features:

1.Automatic 45 degree cutting u-PVC glazing bead profile.

2.Two glazing bead cutting in one time.

3.Automatic saw blade feeding by pneumatic cylinder and moving on precise rod.

4.4 pieces saw blade ensure precise cutting, Double cutting one each end to mill the hook foot.

5.Vertical clamping device and special designed cutting jig ensure stable positioning.

6.Two hand safety operation

7.Friendly using measuring rod.

8.Precise & easy operated measuring table (Only for GBST1800)

$17,500.00

FENSTEK AGBS350 CNC ALU Glass Bead Cutting Machine

AGBS350 Aluminum Window CNC Glazing Bead Cutting Saw

Features:

1. This glazing bead saw is suitable for cutting aluminium glazing bead at 90 degree.

2. Equipped with portable wireless measuring system. Precise and easy measuring.

3. High precision spindle saw blade motor, stable performance.

4. The machine adopts square rail, imported gear rack drive, speedy and high repeat positioning accuracy.

5. Schneider PLC, Servo motor and Schneider servo driver assure long time & stable running.

6. Excellent processing accuracy 0. 1mm

Features:

1. This glazing bead saw is suitable for cutting aluminium glazing bead at 90 degree.

2. Equipped with portable wireless measuring system. Precise and easy measuring.

3. High precision spindle saw blade motor, stable performance.

4. The machine adopts square rail, imported gear rack drive, speedy and high repeat positioning accuracy.

5. Schneider PLC, Servo motor and Schneider servo driver assure long time & stable running.

6. Excellent processing accuracy 0. 1mm

$28,900.00

FENSTEK LJK-600 Automatic Notching Saw. 600 mm Blades

LJK-600

Aluminum Window Notching Saw

Description:

1. This aluminum saw is specially designed for processing aluminum curtain walls and skylights with a special angle on the end surface of the profile.

2. With a magnetic grid control system, realized cutting angle and digital display of the working table height.

3. Two saws are freely changed to +45º~-45º

4. The movement of the saw units is carried out on a servo drive, the cutting angles are set manually, using a special key. The current cutting angle is transmitted to the electronic display for each saw unit separately

Aluminum Window Notching Saw

Description:

1. This aluminum saw is specially designed for processing aluminum curtain walls and skylights with a special angle on the end surface of the profile.

2. With a magnetic grid control system, realized cutting angle and digital display of the working table height.

3. Two saws are freely changed to +45º~-45º

4. The movement of the saw units is carried out on a servo drive, the cutting angles are set manually, using a special key. The current cutting angle is transmitted to the electronic display for each saw unit separately

$42,800.00

FENSTEK CCM160 Corner Crimping Machine 160 mm (pneumatic)

CCM160 Aluminum Window Corner Crimping Machine

Features:

(1) Aluminum window corner crimping machine is used for high efficient assembly of aluminium window and door.

(2) It is driven by air pressure, the action is faster and more stable, and there is no noise, no pollution, safe and reliable.

(3) Fast cutter locking device, adjust tool up and down (magnet type) faster.

(4) Corner crimping height 160 mm, five seconds one corner.

(5) The left and right corner crimping cutter can be adjusted separately, have good synchronism and high quality of corner crimping.

(6) Kinds of assistant position system suit for different window dimension.

(7) More energy saving and environmental protection, the total electricity consumption is less than 100W, greatly reducing the cost of use.

Features:

(1) Aluminum window corner crimping machine is used for high efficient assembly of aluminium window and door.

(2) It is driven by air pressure, the action is faster and more stable, and there is no noise, no pollution, safe and reliable.

(3) Fast cutter locking device, adjust tool up and down (magnet type) faster.

(4) Corner crimping height 160 mm, five seconds one corner.

(5) The left and right corner crimping cutter can be adjusted separately, have good synchronism and high quality of corner crimping.

(6) Kinds of assistant position system suit for different window dimension.

(7) More energy saving and environmental protection, the total electricity consumption is less than 100W, greatly reducing the cost of use.

$16,800.00