Главная

There are 13 products.

BU DAIZER PVC-152, 2007g

USED DAIZER PVC-152, 2007 YEAR OF PRODUCTION. SAW FOR CUTTING GLAZING BEAD, TURKEY

Saw for cutting glazing beads with automatic feed of saw blades, model PVC-152, manufacturer DAIZER, Turkey. Year of manufacture 2007, in excellent condition. Without roller table. Location - Samara. Shipment - pickup, delivery by transport company in the Russian Federation is possible.

Saw for cutting glazing beads with automatic feed of saw blades, model PVC-152, manufacturer DAIZER, Turkey. Year of manufacture 2007, in excellent condition. Without roller table. Location - Samara. Shipment - pickup, delivery by transport company in the Russian Federation is possible.

$700.00

USED COMPRESSOR BEZHETSK KV-30

USED COMPRESSOR BEZHETSK KV-30 PISTON COMPRESSOR

Piston compressor Bezhetsk, model KV30 for 2400 liters per minute, receiver 500 liters. In excellent condition. Two used piston groups are installed. Complete maintenance was carried out with replacement of the main consumables - belts, bearings, main relays, starters, as well as replacement of oil and filters.

Location - Samara. Warehouse storage.

You can check, make a trial run in the warehouse. We will help with shipment.

Piston compressor Bezhetsk, model KV30 for 2400 liters per minute, receiver 500 liters. In excellent condition. Two used piston groups are installed. Complete maintenance was carried out with replacement of the main consumables - belts, bearings, main relays, starters, as well as replacement of oil and filters.

Location - Samara. Warehouse storage.

You can check, make a trial run in the warehouse. We will help with shipment.

$2,700.00

USED COMPRESSOR BEZHETSK KV-30

USED COMPRESSOR BEZHETSK KV-30 PISTON COMPRESSOR

Piston compressor Bezhetsk, model KV30 for 2400 liters per minute, receiver 500 liters. In excellent condition. One piston group is installed new. Complete maintenance was carried out with replacement of the main consumables - belts, bearings, main relays, starters, as well as replacement of oil and filters.

Location - Samara, Warehouse storage. You can check, make a test run in the warehouse. We will help with shipment.

Piston compressor Bezhetsk, model KV30 for 2400 liters per minute, receiver 500 liters. In excellent condition. One piston group is installed new. Complete maintenance was carried out with replacement of the main consumables - belts, bearings, main relays, starters, as well as replacement of oil and filters.

Location - Samara, Warehouse storage. You can check, make a test run in the warehouse. We will help with shipment.

$2,900.00

Dezhong LLWYJ-20 Automatic 20T 3Axis Bending Machine (Siemens control system)

Automatic 20T 3Axis Bending Machine (Siemens control system)

Model - LLWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 330mm-530mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1000*800*1600mm

Weight of machine 800kg

Model - LLWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 330mm-530mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1000*800*1600mm

Weight of machine 800kg

$17,500.00

Dezhong LWYJ-20 Automatic 20T Bending Machine (Siemens control system)

Automatic 20T 3Axis Bending Machine (Siemens control system)

Model - LWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

Model - LWYJ-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

$17,500.00

Dezhong LWYJ-CNC-20 Automatic 20T CNC Bending Machine (Industrial control system)

Automatic CNC Roll Bending Machine (Industrial computer system)

Model - LWYJ-CNC-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-dimensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-15r/min

Y-roller cylinder positioning accuracy ±0.02mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

Model - LWYJ-CNC-20

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-dimensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-15r/min

Y-roller cylinder positioning accuracy ±0.02mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

$39,000.00

Dezhong LSWYJ-20 Automatic 20T Bending Machine (UPVC + ALU))

Automatic 20T 3Axis Bending Machine (Siemens control system)

Equipped by 3 pc of Heating Gun for UPVC processing

Model - LSWYJ-20T

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

Equipped by 3 pc of Heating Gun for UPVC processing

Model - LSWYJ-20T

Description

Power supply 380V/50HZ

Input power 5.9KW

Working pressure 0.2Mpa

Min. diameter of bending 60mm

Max. width of profile H150 x W150mm

Max. diameter of rolls 200mm

Lower shaft center-diamensions 350mm-700mm

Hydraulic cylinder pressure 20T

Roller-holding shaft diameter 65mm

Rotation speed of shaft 1-8r/min

Y-roller cylinder positioning accuracy ±0.1mm

Max. Y-roller travel 200mm

Torque 6000N.m

Size of machine 1300*1100*1500mm

Weight of machine 1000kg

$21,000.00

DS-ICT3826-A Multipurpose Integrated Glass Cutting Table

DS-ICT3826-A Multifunctional Glass Cutting Table

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

$0.00

DS-ICT3826-A-B-T Integrated Glass Cutting Table

DS-ICT3826-A-B-T Multifunctional Glass Cutting Table

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

$0.00

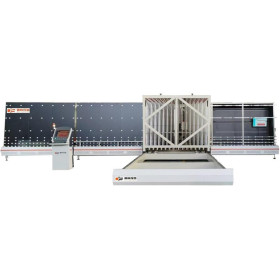

DS-CM4228-D1 Automatic Glass Cutting Line

DS-CM4228-D1

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

$0.00

DS-CM6133-D1 Automatic Glass Cutting Line

DS-CM6133-D1

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 6100×3300 mm to 18000×330

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 6100×3300 mm to 18000×330

$0.00

DISAI DS-LP2520-90 Intelligent Glass Sorting System

DISAI DS-LP2520-90 Intelligent Glass Sorting System

DISAI DS-LP2520-90 Intelligent Glass Sorting System

Description

Vertical glass sorting station: Its primary function is to sort cut glass by customer name, size, and type, and correctly label it for easy identification.

Operating process: Start the equipment, place each glass on the receiving table, and then transfer it to the measuring table (the code has been scanned or the size has been measured during the transfer process, and the glass has been identified). Different glasses will be placed in different bins, and once all the glasses are in the bins, workers can choose how to remove them from the bin. Sorting can be performed by customer, by size, by glass type, or in pairs with specific bins.

DISAI DS-LP2520-90 Intelligent Glass Sorting System

Description

Vertical glass sorting station: Its primary function is to sort cut glass by customer name, size, and type, and correctly label it for easy identification.

Operating process: Start the equipment, place each glass on the receiving table, and then transfer it to the measuring table (the code has been scanned or the size has been measured during the transfer process, and the glass has been identified). Different glasses will be placed in different bins, and once all the glasses are in the bins, workers can choose how to remove them from the bin. Sorting can be performed by customer, by size, by glass type, or in pairs with specific bins.

$0.00

DISAI DS-DR-ISS4228-AB6 Интеллектуальная система хранения листового стекла

DS-DR-ISS4228-AB6 Intelligent Sheet Glass Storage System

SYSTEM DESCRIPTION

Intelligent Glass Storage System: The DISAI intelligent drawer-type glass storage system consists of four components: a glass rack, chassis, power unit, protective net, and control system. It can record the type and quantity of glass in each rack and quickly switch between glass types for efficient production.

Storage system functionality:

1) Can be connected to an office ERP system for real-time inventory data transfer.

2) Easily handle glass of various sizes.

3) The quantity and type of glass in the warehouse can be tracked at any time.

4) Can improve glass production productivity and reduce waste.

5) Increases production efficiency and reduces glass handling time.

SYSTEM DESCRIPTION

Intelligent Glass Storage System: The DISAI intelligent drawer-type glass storage system consists of four components: a glass rack, chassis, power unit, protective net, and control system. It can record the type and quantity of glass in each rack and quickly switch between glass types for efficient production.

Storage system functionality:

1) Can be connected to an office ERP system for real-time inventory data transfer.

2) Easily handle glass of various sizes.

3) The quantity and type of glass in the warehouse can be tracked at any time.

4) Can improve glass production productivity and reduce waste.

5) Increases production efficiency and reduces glass handling time.

$0.00