Главная

There are 204 products.

FENSTEK ADS600*4500 Double Head CNC Arbitrary Angle Saw

FENSTEK ADS600*4500 CNC B2B TWO-HEAD FRONT SAW WITH SERVO DRIVE

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

$63,600.00

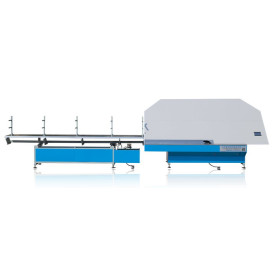

FENSTEK ADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$33,000.00

FENSTEK IADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$43,500.00

NEW KABAN PB2010 Automatic Milling Machine

NEW KABAN PB2010 AUTOMATIC MILLING MACHINE

Automatic machine for milling the end of the molding KABAN PB2010. The equipment worked for one season, the condition is new. Can be checked in operation. Warehouse storage. Location - Samara. We will send to TK in the Russian Federation. Can be purchased by bank transfer without VAT. We will provide a full package of documents - UPD, supply agreement, acceptance certificate, TTN on the road if necessary

Automatic machine for milling the end of the molding KABAN PB2010. The equipment worked for one season, the condition is new. Can be checked in operation. Warehouse storage. Location - Samara. We will send to TK in the Russian Federation. Can be purchased by bank transfer without VAT. We will provide a full package of documents - UPD, supply agreement, acceptance certificate, TTN on the road if necessary

$5,600.00

USED YILMAZ KM213, 2012 Automatic Milling Machine

USED YILMAZ KM213, 2012 YEAR. AUTOMATIC MILLING MACHINE, TURKEY

Automatic machine for milling the end of the molding, for one cutter, WITHOUT quick release, with pneumatic feed, variable angle, pneumatic clamps. Additionally, you can install a cooling system for working with aluminum. Manufacturer YILMAZ, Turkey. Model KM-213. Year of manufacture 2012. Condition is excellent. Location - Samara. Shipment - pickup, delivery by a transport company is possible.

Automatic machine for milling the end of the molding, for one cutter, WITHOUT quick release, with pneumatic feed, variable angle, pneumatic clamps. Additionally, you can install a cooling system for working with aluminum. Manufacturer YILMAZ, Turkey. Model KM-213. Year of manufacture 2012. Condition is excellent. Location - Samara. Shipment - pickup, delivery by a transport company is possible.

$2,700.00

YILMAZ KM215S Automatic Milling Machine

Automatic machine for milling of impost YILMAZ KM215, with quick release, 2013. In excellent condition. Everything works, you can come and check. A new cooling system is installed, for working with aluminum. The equipment is in Samara, in our warehouse. We will help with shipment.

Cashless payment without VAT, we will provide a package of documents - supply agreement, UPD, acts, TTN.

Cashless payment without VAT, we will provide a package of documents - supply agreement, UPD, acts, TTN.

$3,000.00

YILMAZ KD400P Single Head Pendle Saw

The stationary single-head saw (pendulum) Yilmaz KD400P is used for cutting aluminum and PVC profiles. The profile clamp is pneumatic, the saw blade is fed manually. The profile cutting angle is 15°, 22.5°, 30°, 45° and 90°, respectively. Additionally, it can be equipped with a measuring roller table MKN300.

For sale is a used YILMAZ KD400P machine. Currently - warehouse storage, the equipment is not in operation. The cut-off saw has undergone routine repairs, the main mechanism for lowering and lifting the saw unit has been replaced, a new 350 mm saw blade has been installed. The coolant supply system is not installed, but it can be considered as a separate option. It is also possible to equip this machine with a new manual measuring roller table MKN 300, payment on a separate invoice.

For sale is a used YILMAZ KD400P machine. Currently - warehouse storage, the equipment is not in operation. The cut-off saw has undergone routine repairs, the main mechanism for lowering and lifting the saw unit has been replaced, a new 350 mm saw blade has been installed. The coolant supply system is not installed, but it can be considered as a separate option. It is also possible to equip this machine with a new manual measuring roller table MKN 300, payment on a separate invoice.

$3,000.00

YILMAZ TK503, 2012г.в. Single Head Welding Machine

Single-head welding machine YILMAZ TK503. Economy option. The machine is in excellent condition, a new temperature controller is installed. The machine is fully assembled, warehouse storage.

Location: Samara. Shipment - pickup, can be sent to a transport company or as additional cargo

Upon request, we will provide additional photos and videos of the work. A video call with the warehouse in real time is possible. You can also come personally to our warehouse, bring your samples and test the machine in operation on samples. We will connect, demonstrate the work.

The sale of the machine is carried out by bank transfer without VAT, we will provide instructions in electronic form. A package of documents - a supply agreement, an acceptance certificate, UPD, TTN for transportation.

Location: Samara. Shipment - pickup, can be sent to a transport company or as additional cargo

Upon request, we will provide additional photos and videos of the work. A video call with the warehouse in real time is possible. You can also come personally to our warehouse, bring your samples and test the machine in operation on samples. We will connect, demonstrate the work.

The sale of the machine is carried out by bank transfer without VAT, we will provide instructions in electronic form. A package of documents - a supply agreement, an acceptance certificate, UPD, TTN for transportation.

$3,000.00

copy of YILMAZ TK503, Single Head Welding Machine 2012

Single-head welding machine YILMAZ TK501. Standard edition. The machine is in excellent condition, a new temperature controller is installed. The machine is fully assembled, warehouse storage.

Location: Samara. Shipment - pickup, can be sent to a transport company or as additional cargo

Upon request, we will provide additional photos and videos of the work. A video call with the warehouse in real time is possible. You can also come personally to our warehouse, bring your samples and test the machine in operation on samples. We will connect, demonstrate the work.

The sale of the machine is carried out by bank transfer without VAT, we will provide instructions in electronic form. A package of documents - a supply agreement, an acceptance certificate, UPD, TTN for transportation.

Location: Samara. Shipment - pickup, can be sent to a transport company or as additional cargo

Upon request, we will provide additional photos and videos of the work. A video call with the warehouse in real time is possible. You can also come personally to our warehouse, bring your samples and test the machine in operation on samples. We will connect, demonstrate the work.

The sale of the machine is carried out by bank transfer without VAT, we will provide instructions in electronic form. A package of documents - a supply agreement, an acceptance certificate, UPD, TTN for transportation.

$3,200.00

USED YILMAZ FR226 Copy Router UPVC automatic, 2014

USED YILMAZ FR226 2014 YEAR OLD COPY-MILLING MACHINE, TURKEY

Automatic copy-milling machine YILMAZ FR-226, for milling a triple hole for handles, as well as a groove for a lock. Year of manufacture 2014, the machine is in excellent condition. Currently in warehouse storage. Location - Samara. We can send photos and videos WhatsApp, and also demonstrate the work in person if the client comes to the warehouse. We will help with shipment, pack the equipment in stretch film, we can hand it over to the TC. We sell by bank transfer without VAT, contract, acts pp, UPD and TTN.

Automatic copy-milling machine YILMAZ FR-226, for milling a triple hole for handles, as well as a groove for a lock. Year of manufacture 2014, the machine is in excellent condition. Currently in warehouse storage. Location - Samara. We can send photos and videos WhatsApp, and also demonstrate the work in person if the client comes to the warehouse. We will help with shipment, pack the equipment in stretch film, we can hand it over to the TC. We sell by bank transfer without VAT, contract, acts pp, UPD and TTN.

$3,600.00

USED YILMAZ FR226 Copy Router UPVC, 2013

USED YILMAZ FR225 2013 YEAR OLD COPY-MILLING MACHINE, TURKEY

Manual feed copy-milling machine YILMAZ FR-225, for milling a triple hole for handles, as well as a groove for a lock. Year of manufacture 2017, the machine is in excellent condition. Currently in warehouse storage. Location - Samara. We can send photos and videos WhatsApp, and also demonstrate the work in person if the client comes to the warehouse. We will help with shipment, pack the equipment in stretch film, we can hand it over to the TC. We sell by bank transfer without VAT, contract, acts pp, UPD and TTN.

Manual feed copy-milling machine YILMAZ FR-225, for milling a triple hole for handles, as well as a groove for a lock. Year of manufacture 2017, the machine is in excellent condition. Currently in warehouse storage. Location - Samara. We can send photos and videos WhatsApp, and also demonstrate the work in person if the client comes to the warehouse. We will help with shipment, pack the equipment in stretch film, we can hand it over to the TC. We sell by bank transfer without VAT, contract, acts pp, UPD and TTN.

$2,900.00

DJJ07 Automatic Butyl Extruder

Butyl coating machine-DJJ07

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency.

DJJ07 Butyl Coating Machine

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency. Adjust the distance between two glue nozzle automatically. Adjust the glue output automatically according to running speed. It has the advantage of long service life and high degree of automation, etc

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency.

DJJ07 Butyl Coating Machine

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency. Adjust the distance between two glue nozzle automatically. Adjust the glue output automatically according to running speed. It has the advantage of long service life and high degree of automation, etc

$0.00

LBP2500C IG LINE 2,5 m

Insulating glass machine C Series (Machinery of this series adopts IG Outer-panel Assembly. Effect high-speed IG production efficiency

Insulating Glass Production Line C Series

Outer-panel Assembly Insulating Glass Production Line

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, out-panel (and inner-panel) assembly, large stroke press machine and output section (title table), adopts advanced IG manufacture technology and craft. This production line can choose out-panel assembly or inner-panel assembly to process same edge single and double insulating glass un

Insulating Glass Production Line C Series

Outer-panel Assembly Insulating Glass Production Line

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, out-panel (and inner-panel) assembly, large stroke press machine and output section (title table), adopts advanced IG manufacture technology and craft. This production line can choose out-panel assembly or inner-panel assembly to process same edge single and double insulating glass un

$0.00

LBP2500S IG Line 2,5 m

Insulating glass machine S Series (Machinery of this series is with argon gas filling on-line and double station in aluminum spacer location section)

The production line adopts advanced manufacturing craft and technology of insulating glass making. It is mainly composed of glass loading, cleaning and drying, transmission, dual-station light inspection and aluminum spacer location, automatic assembly, large stroke pressing (internal assembly, argon gas filling inline) and transmission after pressing into double glazing glass

The production line adopts advanced manufacturing craft and technology of insulating glass making. It is mainly composed of glass loading, cleaning and drying, transmission, dual-station light inspection and aluminum spacer location, automatic assembly, large stroke pressing (internal assembly, argon gas filling inline) and transmission after pressing into double glazing glass

$0.00

ZFGJ-02B Automatic Desiccant Filling Machine

Automatic molecular sieve filling machine

Adopt PLC control system and touch human-machine interface

ZFGJ-02B Automatic Desiccant Filling Machine

Main features

1. Adopt PLC control system and touch human-machine interface.

2. Can fill bendable and non-bendable aluminum frame.

3. Adjust filling height according to the various sizes of the aluminum frame.

4. High filling speed by drilling holes in the back.

5. Seal the filling holes automatically.

6. Monitoring the quantity of desiccant and replenish material automatically.

7. The model can be with double-station operating, save manpower, high efficiency

Adopt PLC control system and touch human-machine interface

ZFGJ-02B Automatic Desiccant Filling Machine

Main features

1. Adopt PLC control system and touch human-machine interface.

2. Can fill bendable and non-bendable aluminum frame.

3. Adjust filling height according to the various sizes of the aluminum frame.

4. High filling speed by drilling holes in the back.

5. Seal the filling holes automatically.

6. Monitoring the quantity of desiccant and replenish material automatically.

7. The model can be with double-station operating, save manpower, high efficiency

$0.00

ZLZW-02 Aluminium Spacer Bending Machine

Automatic spacer bending machine

Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

ZLZW02 Automatic aluminum spacer bending machine

Main features

1. Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

2. Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc).

3. Aluminum frame have smooth arc, which is beautiful after butyl coating.

4. Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency.

5. Can feed four different size of aluminum spacer with four store tanks.

6. Automactic avoid spacer joint when bending and cutting spacer.

7. Can do shaped aluminum frame.

Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

ZLZW02 Automatic aluminum spacer bending machine

Main features

1. Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

2. Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc).

3. Aluminum frame have smooth arc, which is beautiful after butyl coating.

4. Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency.

5. Can feed four different size of aluminum spacer with four store tanks.

6. Automactic avoid spacer joint when bending and cutting spacer.

7. Can do shaped aluminum frame.

$0.00

SDQ-III Two Component Sealant Extruder

Two component sealant extruder (SDQ-III)

It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism

SDQ-III Two-component Sealant Extruders

Main features

1. It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism.

2. The needle one-way valve could ensure that the mixture will not reflow to avoid the pipe solidification.

3. Fully closed curing agent glue system, avoid curing agent and air contact and curing.

4. Sensitive high-pressure protective value makes the operation in safe condition.

5. Gas pressure driven has the performance of stable pressure, uniform output.

6. Adopt international popular static reciprocating mixer, mixing more uniform.

7. The main raw materials: silicone sealant, polysulfide sealant, polyurethane adhesive

It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism

SDQ-III Two-component Sealant Extruders

Main features

1. It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism.

2. The needle one-way valve could ensure that the mixture will not reflow to avoid the pipe solidification.

3. Fully closed curing agent glue system, avoid curing agent and air contact and curing.

4. Sensitive high-pressure protective value makes the operation in safe condition.

5. Gas pressure driven has the performance of stable pressure, uniform output.

6. Adopt international popular static reciprocating mixer, mixing more uniform.

7. The main raw materials: silicone sealant, polysulfide sealant, polyurethane adhesive

$0.00

DJJ06 Automatic Butyl Extruder

Butyl coating machine-DJJ06

Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate

Main features

1. Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate, etc.

2. Adopts PLC control system with touch screen interface.

3. Adjust the distance between two glue nozzle by automatic hydraulic cylinder, fast and convenient.

4. Can glue round spacer.

5. Five gear frequency control.

6. The glue tanker diameter 200mm, length 450mm, is suitable for all kinds of butyl.

7. 24 hour timer switch, saving warm-up time, improve work efficiency.

Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate

Main features

1. Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate, etc.

2. Adopts PLC control system with touch screen interface.

3. Adjust the distance between two glue nozzle by automatic hydraulic cylinder, fast and convenient.

4. Can glue round spacer.

5. Five gear frequency control.

6. The glue tanker diameter 200mm, length 450mm, is suitable for all kinds of butyl.

7. 24 hour timer switch, saving warm-up time, improve work efficiency.

$0.00