Главная

There are 49 products.

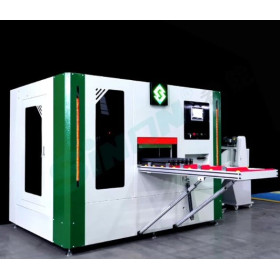

SINON JQK9-CNC-130 CNC Corner Cleaning Machine (9 tools)

JQK9-CNC-130 CNC PVC WINDOW CLEANING MACHINE (9 TOOLS)

1. CNC machine used to clean the welding slag in the corners of the window frame and sash at 90°.

2. Can process the outer corner, the upper and lower part of the corner surface, the inner corner sealing rubber groove and the inner plane of the casement window, the sealing groove of the outer corner of the casement window, the inner corner joint of the sliding window.

3. Six CNC corner cleaning tools control the process flow, simplifying the operation.

4. This machine has the function of compensating the corner arches.

5. The machine can store more than 100 profile processing programs.

6. According to the conditions on the site, the values are randomly dialed, and the processing program is adjusted so that the weld seams with deviations due to the dimensional accuracy of the profiles can be effectively cleaned.

1. CNC machine used to clean the welding slag in the corners of the window frame and sash at 90°.

2. Can process the outer corner, the upper and lower part of the corner surface, the inner corner sealing rubber groove and the inner plane of the casement window, the sealing groove of the outer corner of the casement window, the inner corner joint of the sliding window.

3. Six CNC corner cleaning tools control the process flow, simplifying the operation.

4. This machine has the function of compensating the corner arches.

5. The machine can store more than 100 profile processing programs.

6. According to the conditions on the site, the values are randomly dialed, and the processing program is adjusted so that the weld seams with deviations due to the dimensional accuracy of the profiles can be effectively cleaned.

$27,200.00

SINON LDJZ1-120 Pneumatic Screw Driver

SINON LDJZ1-120 Pneumatic Screw Driver

LDJZ1-120 is used for fastening the Reinforcement of the PVC window and door /

PLC control system, France Schneider system

FEATURES:

● This machine used for fastening the Reinforcement of the PVC window and door.

● Adopt PLC programming controller, it’s reliable and stably.

● The machine head is adjustable from front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

● Auto feeding and distributing screws by special feeding device, with without screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory.

● With standard two sets of 2M supporting bracket.

LDJZ1-120 is used for fastening the Reinforcement of the PVC window and door /

PLC control system, France Schneider system

FEATURES:

● This machine used for fastening the Reinforcement of the PVC window and door.

● Adopt PLC programming controller, it’s reliable and stably.

● The machine head is adjustable from front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

● Auto feeding and distributing screws by special feeding device, with without screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory.

● With standard two sets of 2M supporting bracket.

$5,200.00

LJKJ-CNC-600 CNC Notching Saw Aluminium

For the first time in Russia. New model of CNC Facade Notching Saw.

Manufactured by SINON, China.

High-quality equipment from an authorized dealer in Russia.

We deliver to order.

Model LJKJ-CNC-600. CNC machine, single 600 mm diameter saw blade, cooling, 180-degree blade rotation. Extensive library of possible notching options. Any non-standard façade profile notches. High blade movement and rotation speed. The portal moves in three axes, and the blade angle is adjusted automatically. The work table can also be rotated to the desired angle, with the set angle displayed on the electronic display.

Delivery time is 3-4 months. We work with VAT under contract. Import into Russia is completely legal, official delivery, no gray areas. Reliable, efficient, and safe. We have been operating in the Russian market for over 20 years.

The price of the equipment includes delivery to the client, commissioning work, and training of personnel to operate the equipment.

Manufactured by SINON, China.

High-quality equipment from an authorized dealer in Russia.

We deliver to order.

Model LJKJ-CNC-600. CNC machine, single 600 mm diameter saw blade, cooling, 180-degree blade rotation. Extensive library of possible notching options. Any non-standard façade profile notches. High blade movement and rotation speed. The portal moves in three axes, and the blade angle is adjusted automatically. The work table can also be rotated to the desired angle, with the set angle displayed on the electronic display.

Delivery time is 3-4 months. We work with VAT under contract. Import into Russia is completely legal, official delivery, no gray areas. Reliable, efficient, and safe. We have been operating in the Russian market for over 20 years.

The price of the equipment includes delivery to the client, commissioning work, and training of personnel to operate the equipment.

$50,500.00

SZA-400 ULTRA 5-Axis CNC End Milling Machine

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

$31,800.00

SZA-400V ULTRA 5-Axis CNC End Milling Machine

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400V. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows. Variable Angle of Milling

Model: SZA400V

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400V. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows. Variable Angle of Milling

Model: SZA400V

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

$36,000.00

Used MURAT KC258, 2017. Twin-Head Welding Machine

MURAT KC258, 2017

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

$0.00

Used MURAT KT-804 Sash Hardware Assembly Table

MURAT KT-804 HARDWARE ASSEMBLY STATION

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

$0.00

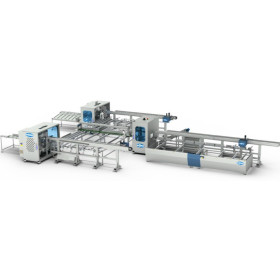

Used Haffner NR-242 Cutting&Milling Machining Center UPVC

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

$0.00

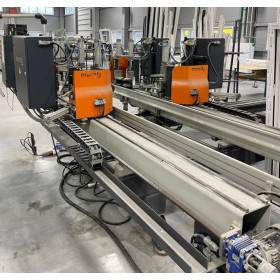

Used MURAT KD658/20 CNC 4-HEAD Welding Machine

KD658/20 4-Head Horizontal Welding Machine, 2019

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

$0.00