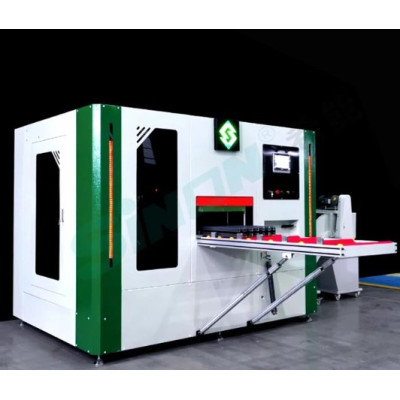

SZA-400 ULTRA 5-Axis CNC End Milling Machine

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

Delivery throughout Russia - by transport company.

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

DESCRIPTION

The Ultra 5 Axis CNC router is a 5-axis, 4-blade, ultra-efficient, intelligent router designed by our company for the system door and window market. It is suitable for milling end faces of glazing beads and reinforced glazing beads for a wide range of aluminum alloy profiles for high-end system windows. It works best with a workstation (Aluminum Profile Cutting and Processing Center).

FUNCTIONALITY

1. 5-axis control of the upper, lower, front, and rear positions of two spindle motors.

2. Intelligent tool position adjustment. The tool can be moved up and down, forward and backward, and can process various structures such as stepped surfaces, rectangular grooves, and tenons.

3. A highly efficient intelligent module can handle code processing, and 5-axis, 4-tool, double-sided milling is more efficient.

4. The absolute value of the rail makes the system more stable and improves milling accuracy.

5. Adjustable tools require no adjustment when machining different profiles, shortening the production preparation cycle and reducing costs.

6. The profile stiffener can be cut in a single operation.

7. The tool has a large diameter, high cutting speed, and good surface finish.

8. The program has a built-in memory module, so you only need to set up any profile once and save it.

A COMMERCIAL OFFER WILL BE PROVIDED UPON YOUR REQUEST

The supply contract is concluded and all payments are made inclusive of VAT.

The delivery time is calculated individually, depending on the current workload of the manufacturer.