List of products by brand SINON, Китай

Since 2010, Graphic Corner offers a large choice of quality posters, available on paper and many other formats.

There are 42 products.

SINON GCGZD-CNC-800 CNC Copy Router Machine, 3-Axis

3+1 Axis CNC CONTROLLED COPY ROUTER MACHINE

Brand: China SinonModel: GCGZD-CNC-800Input power source: 380V/50Hz or CustomziedTotal power: 5KwMain spindle power: 3.5kwMain spindle speed: 0-18000rpmX axis processing range: 800mmY axis processing range: 200mmZ axis processing range: 145mmDimension: 1300×1500×1700mmWeight: 800kg

Brand: China SinonModel: GCGZD-CNC-800Input power source: 380V/50Hz or CustomziedTotal power: 5KwMain spindle power: 3.5kwMain spindle speed: 0-18000rpmX axis processing range: 800mmY axis processing range: 200mmZ axis processing range: 145mmDimension: 1300×1500×1700mmWeight: 800kg

$12,850.00

SINON LJRZ2-CNC-600 * 6000 Double Head CNC Cutting Machine (full automatic, servo-drivers, arbitrary angles)

SINON LJRZ2-CNC-600 * 6000

DOUBLE HEAD CNC AUTOMATIC CUTTING MACHINE, ARBITRARY ANGLES ADJUST

1. The double head CNC front saw is an advanced equipment used for cutting aluminum profiles.

2. This machine has a neat and stylish appearance, modeled on the European style.

3. The new closed-loop control system used in this machine is highly efficient, ensuring precise cutting.

4. The machine is equipped with a direct drive saw blade, which uses a lever-turn cutting type, making the blade feed by the pneumatic-hydraulic damping cylinder and ensuring smooth cutting.

5. The imported saw blade used in this machine has high precision, making the cutting surface smooth.

6. The cutting angle of the machine can be adjusted in the range of 45°~157.5° by the servo motor driving the speed reducer.

DOUBLE HEAD CNC AUTOMATIC CUTTING MACHINE, ARBITRARY ANGLES ADJUST

1. The double head CNC front saw is an advanced equipment used for cutting aluminum profiles.

2. This machine has a neat and stylish appearance, modeled on the European style.

3. The new closed-loop control system used in this machine is highly efficient, ensuring precise cutting.

4. The machine is equipped with a direct drive saw blade, which uses a lever-turn cutting type, making the blade feed by the pneumatic-hydraulic damping cylinder and ensuring smooth cutting.

5. The imported saw blade used in this machine has high precision, making the cutting surface smooth.

6. The cutting angle of the machine can be adjusted in the range of 45°~157.5° by the servo motor driving the speed reducer.

$54,500.00

SINON Thermal Break Aluminium Assembly Machines Set (non CNC)

Thermal Break Assembly Machine

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of knurling machine with strip feeder device

1 set of rolling machine

Daily capacity is 5~6 Tons per 10 hours

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of knurling machine with strip feeder device

1 set of rolling machine

Daily capacity is 5~6 Tons per 10 hours

$25,800.00

SINON Thermal Break Aluminium Assembly Machines Set (CNC)

Thermal Break Assembly Machine

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of CNC knurling machine with strip feeder device

1 set of CNC rolling machine

Daily capacity is 5~6 Tons per 10 hours

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of CNC knurling machine with strip feeder device

1 set of CNC rolling machine

Daily capacity is 5~6 Tons per 10 hours

$67,500.00

SINON SJ02-350

SINON SJ02-350 SINGLE-HEAD PENDULUM SAW

Automatic single-head pendulum saw for cutting PVC profiles (350mm) Saw blade Φ350mm×φ30mm. Cutting width: Max 200mm Cutting height: Max 100mm. Cutting angle: 45/90/135

Automatic single-head pendulum saw for cutting PVC profiles (350mm) Saw blade Φ350mm×φ30mm. Cutting width: Max 200mm Cutting height: Max 100mm. Cutting angle: 45/90/135

$3,250.00

FENSTEK SA2400 Sash Hardware Assembly Table with Tripple Drilling

1. Used to assembly hardware systems such as Tilt, Tilt & Turn, Parallel Slide, Pivot, Slide-fold, Double Sash and Sliding Systems on different types, various sizes of window & door sash profiles without tape measure and pencil using, without need for molds and templates, provides speedy, high quality and standard assembling.2.Equipped with an industrial computer and a barcode scanner, it can be connected to other machines on the production line for data exchange3.Sash Assembly table4.Servo positioning espagnolette punching device, used for punching locking strips of various types of window sashes5.Full Automatic Screwing, Automatic screw feeding unit, Infrared indicator .6.Movable, adjustable triple handle hole drilling group with reinforced profile & upvc profile together.7.Latch Slot milling8.Two Holes Drilling On the sash with Stopper

$64,700.00

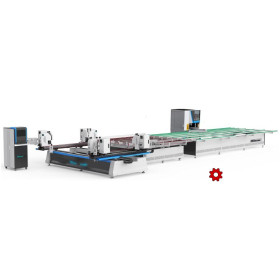

SINON SZA-610 Cutting&Milling Center Aluminium

Aluminium Profile Cutting And Machining Center

Its super-efficient workstation with integrates ERP door and window software + 3-angles efficient sawing + 3-station 4-direction 8-axis drilling and milling + laser scribingModel: SZA610Input Voltage: 380V/50Hz/3P or CustomizedTotal power: 45.55KWSaw blade specifications:∮550*4.4*∮30*120Sawing angle +45º 90°-45°Sectional size of sawed profile (width×height):180*150mmWeight about 12T

Its super-efficient workstation with integrates ERP door and window software + 3-angles efficient sawing + 3-station 4-direction 8-axis drilling and milling + laser scribingModel: SZA610Input Voltage: 380V/50Hz/3P or CustomizedTotal power: 45.55KWSaw blade specifications:∮550*4.4*∮30*120Sawing angle +45º 90°-45°Sectional size of sawed profile (width×height):180*150mmWeight about 12T

$195,300.00

SINON GCGZD-CNC-3000 ATC-HANS Milling Center ALU

Tool Change CNC Aluminium Processing Machine HANS System

Model:GCGZD-CNC series, GCGZD-CNC-2500/3000/3500(X-way stroke)Power:380V 50Hz 3P or customizationCNC processing machine for aluminium profile, full automatic aluminium profile milling and drilling machine

Model:GCGZD-CNC series, GCGZD-CNC-2500/3000/3500(X-way stroke)Power:380V 50Hz 3P or customizationCNC processing machine for aluminium profile, full automatic aluminium profile milling and drilling machine

$41,000.00

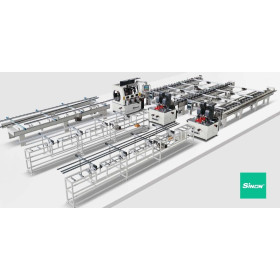

SINON SHQXJ01 Welding & Corner Cleaning Line

SINON SHQXJ01 Welding & Corner Cleaning Line

/ Welding cleaning production line for pvc door and window / SHQXJ01 /

The production line is specialized in welding and cleaning outer corners of colored PVC profiles. It can be welded and formed into a rectangular window frame at one time, and the upper and lower welds are cleaned. Then, the completed window is transferred to the corner cleaning unit through the transfer workbench to complete the corner cleaning of the window. CNC Corner Cleaning

/ Welding cleaning production line for pvc door and window / SHQXJ01 /

The production line is specialized in welding and cleaning outer corners of colored PVC profiles. It can be welded and formed into a rectangular window frame at one time, and the upper and lower welds are cleaned. Then, the completed window is transferred to the corner cleaning unit through the transfer workbench to complete the corner cleaning of the window. CNC Corner Cleaning

$93,600.00

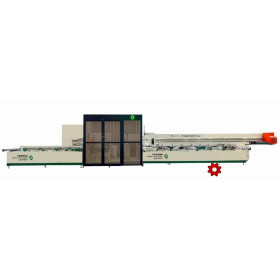

SINON SHQXJ02 Welding & Corner Cleaning Line UPVC

SINON SHQXJ02 Welding & Corner Cleaning Line UPVC

HORIZONTAL 4-HEAD WELDING MACHINE, DOUBLE CORNER CLEANING STATION

Features:

The production line is specialized in welding and cleaning outer corners of colored PVC profiles. It can be welded and formed into a rectangular window frame at one time, and the upper and lower welds are cleaned. Then, the completed window is transferred to the corner cleaning unit through the transfer workbench to complete the corner cleaning of the window. Double CNC Corner Cleaning Station.

HORIZONTAL 4-HEAD WELDING MACHINE, DOUBLE CORNER CLEANING STATION

Features:

The production line is specialized in welding and cleaning outer corners of colored PVC profiles. It can be welded and formed into a rectangular window frame at one time, and the upper and lower welds are cleaned. Then, the completed window is transferred to the corner cleaning unit through the transfer workbench to complete the corner cleaning of the window. Double CNC Corner Cleaning Station.

$153,700.00

SINON GCGZD-CNC-3000 CNC Copy Router 3-Axis

CNC Aluminium Profile Milling Machine

SINON GCGZD-CNC-3000

Input power: 380V/50Hz or customized voltageTotal power: 7.5KwMain spindle speed: 0-24000rpmX axis processing range: 2500mmY axis processing range: 300mmZ axis processing range: 330mmDimension: 4600×1350×1900mmWeight: 2000kg

$32,500.00

SINON DX05A-200 Automatic End Milling Machine

SINON DX05A-200 PVC AND ALUMINUM MILLING MACHINE. CUTTERS 200 MM.

End Milling Machine For Aluminum Profile DX05A-200 / Medium-type end milling machine / Used for milling the end surface of aluminum profiles for windows and doors DESCRIPTION: ● The cutter disc is simple, thanks to the original design of the interaction of two cutting discs. ● Gas-driven and spray cooling system improves the milling effect and increases the durability of the tool. ● Thanks to the precise manufacturing process, the rotation of the axis and the bearing seat becomes more stable, the noise and vibration are much lower than other models.

End Milling Machine For Aluminum Profile DX05A-200 / Medium-type end milling machine / Used for milling the end surface of aluminum profiles for windows and doors DESCRIPTION: ● The cutter disc is simple, thanks to the original design of the interaction of two cutting discs. ● Gas-driven and spray cooling system improves the milling effect and increases the durability of the tool. ● Thanks to the precise manufacturing process, the rotation of the axis and the bearing seat becomes more stable, the noise and vibration are much lower than other models.

$6,200.00

SINON DX06A-250 Automatic End Milling Machine

SINON DX06A-250 MILLING MACHINE FOR PVC AND ALUMINIUM. CUTTERS 250 MM.

Automatic machine for serial milling of PVC mullions and aluminum crossbars Model - DX06A-250

Main Features

1. The machine is used for milling and cutting the end face of aluminum alloy door and window profile to ensure the connection between the frame and the end face of the mullion/transom.

2. Five sets of tools can be adjusted up and down, left and right to meet the processing requirements of different profiles.

3. No need to adjust the tools, which improves the production efficiency and reduces the cost.

4. It can process multiple profiles at the same time and has high production efficiency.

5. The feeding system uses variable speed feeding mechanism, the milling is more stable and the accuracy is higher.

6. The saw blade has a large diameter and high cutting precision.

Automatic machine for serial milling of PVC mullions and aluminum crossbars Model - DX06A-250

Main Features

1. The machine is used for milling and cutting the end face of aluminum alloy door and window profile to ensure the connection between the frame and the end face of the mullion/transom.

2. Five sets of tools can be adjusted up and down, left and right to meet the processing requirements of different profiles.

3. No need to adjust the tools, which improves the production efficiency and reduces the cost.

4. It can process multiple profiles at the same time and has high production efficiency.

5. The feeding system uses variable speed feeding mechanism, the milling is more stable and the accuracy is higher.

6. The saw blade has a large diameter and high cutting precision.

$11,000.00

SINON DX09-CNC-250 CNC Milling Machine

SINON DX09-CNC-250 CNC MILLING STATION, ALUMINUM

END milling machine for aluminum and PVC windows and doors

Highly efficient and multifunctional

CNC aluminum and PVC window and door making machine, profile face milling machine, suitable for processing trunnions and reinforced trunnions. This type of machine is designed for mass production

7 servo motors, 7 axes

There are 3 cutters in this machine. The three knives can move up and down, back and forth in 6 axes, and the total horizontal movement is 1 axis, so there are 7 axes in the machine.

END milling machine for aluminum and PVC windows and doors

Highly efficient and multifunctional

CNC aluminum and PVC window and door making machine, profile face milling machine, suitable for processing trunnions and reinforced trunnions. This type of machine is designed for mass production

7 servo motors, 7 axes

There are 3 cutters in this machine. The three knives can move up and down, back and forth in 6 axes, and the total horizontal movement is 1 axis, so there are 7 axes in the machine.

$33,500.00

SINON DX03-CNC-300 CNC Milling Machine

SINON DX03-CNC-300 CNC MILLING STATION, ALUMINUM

Automatic CNC station for milling the ends of the MULLIONS Model - DX03-CNC-300

Technical Description

1. This machine is suitable for processing aluminum window end profiles, transoms, and restoring the end milling process of journal profile.

2. Three-axis control, digital adjustment of tool up and down, front and back position, adaptable to different processing shapes and sizes.

3. Automatic processing, easy to operate. The program can be saved, and one kind of profile only needs to be adjusted once.

4. Adjustable tools eliminate the need to order tools when processing different profiles, thereby shortening the production preparation cycle and reducing costs.

5. Multiple profiles can be milled at the same time to improve work efficiency.

6. Equipped with servo motor to ensure smooth and efficient operation.

7. Large tool diameter, high cutting speed and good surface quality.

8. Equipped with linear guides to realize high-precision processing

Automatic CNC station for milling the ends of the MULLIONS Model - DX03-CNC-300

Technical Description

1. This machine is suitable for processing aluminum window end profiles, transoms, and restoring the end milling process of journal profile.

2. Three-axis control, digital adjustment of tool up and down, front and back position, adaptable to different processing shapes and sizes.

3. Automatic processing, easy to operate. The program can be saved, and one kind of profile only needs to be adjusted once.

4. Adjustable tools eliminate the need to order tools when processing different profiles, thereby shortening the production preparation cycle and reducing costs.

5. Multiple profiles can be milled at the same time to improve work efficiency.

6. Equipped with servo motor to ensure smooth and efficient operation.

7. Large tool diameter, high cutting speed and good surface quality.

8. Equipped with linear guides to realize high-precision processing

$12,800.00

SINON LSXZ1B-125 Copy Routing Machine

LSXZ1B-125 Single-spindle Copy Router Machine PATTERN COPY ROUTING MACHINE is used to process the lock hole, water slot and hardware hole of PVC and aluminum windows and doors. Standard molding board to control the hole size, the copying speed is 1: 1; Equipped with high-speed route copying milling head to ensure the milling accuracy. The double-pitch pattern copying needle design is suitable for different hole sizes. It can process various grooves controlled by the ruler

$3,500.00

SINON LDZX01-100 Copy Routing Machine

SINON LDZX01-100 COPY ROUTING MACHINE

High-speed heavy-duty copying machine for aluminum window making machine Features: ● It is used to process several types of holes, grooves and water gaps on aluminum and PVC windows and doors or curtain walls. It is in the middle of the aluminum window making machine line. ● It features compact structure, nice design, reasonable volume, and the air pressure adjusts the starting of the motor. ● Easy replacement of copy guide plate, large useful volume, high efficiency and convenient operation ensure continuous processing and safe operation

High-speed heavy-duty copying machine for aluminum window making machine Features: ● It is used to process several types of holes, grooves and water gaps on aluminum and PVC windows and doors or curtain walls. It is in the middle of the aluminum window making machine line. ● It features compact structure, nice design, reasonable volume, and the air pressure adjusts the starting of the motor. ● Easy replacement of copy guide plate, large useful volume, high efficiency and convenient operation ensure continuous processing and safe operation

$8,800.00

SINON SSKC02-100 UPVC Copy Router with Tripple Drilling

SINON SSKC02-100 PVC Copy Milling Machine

1. Used for milling and triple drilling of aluminum profiles and PVC profiles.

2. The scale of the copy milling operation is 1: 1

3. Drilling and milling various holes for installing door locks, easy to operate

4. Equipped with standard templates

1. Used for milling and triple drilling of aluminum profiles and PVC profiles.

2. The scale of the copy milling operation is 1: 1

3. Drilling and milling various holes for installing door locks, easy to operate

4. Equipped with standard templates

$3,600.00

SINON LSKC03-100 UPVC Lock Hole Drilling Machine

SINON LSKC03-100 UPVC Lock Hole Drilling Machine

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.2. For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

Main Features

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.

2.For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

3. Horizontal triple heads drilling and vertical copy router with special cutout working table to realize one time finishing.

4.Lock hole Triple heads are behind of the machine bed.

5.Easy adjustment of the height of the triple drill head

6.Adopts gas-liquid damping automatic feeding for Triple drilling heads, reducing the labor intensity of workers.

7. Routing to stops or universal template in 1:1 ratio.

8. Pneumatic horizontal clamping.

9. Equipped with standard hole template. Plain template is standard equipped or specific designed.

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.2. For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

Main Features

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.

2.For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

3. Horizontal triple heads drilling and vertical copy router with special cutout working table to realize one time finishing.

4.Lock hole Triple heads are behind of the machine bed.

5.Easy adjustment of the height of the triple drill head

6.Adopts gas-liquid damping automatic feeding for Triple drilling heads, reducing the labor intensity of workers.

7. Routing to stops or universal template in 1:1 ratio.

8. Pneumatic horizontal clamping.

9. Equipped with standard hole template. Plain template is standard equipped or specific designed.

$5,200.00