SINON, КИТАЙ

There are 41 products.

SINON LJZ2C-CNC-500(550, 600)*4200 Double Head Cutting Machine (automatic)

Aluminium Double Head Cutting Machine

LZJ2C-CNC-500*4200 / Full SIEMENS CNC system

1. Suitable for cutting Aluminum profiles and curtain wall profile

2. Can cut very small piece (cnc model)

3. Adopts imported industry grade computer system, closed-loop controlled, high precision and quick shift for cutting size.(CNC model)

4. Adopts imported servo motor and ball screw driver mode(CNC model).

5. Optimized function: optimizing to cut according to the working list(CNC model).

6. Tabulation cutting function: several kinds of profiles can be selected quickly.

7. Angle automatic indexing: -45°、90°

LZJ2C-CNC-500*4200 / Full SIEMENS CNC system

1. Suitable for cutting Aluminum profiles and curtain wall profile

2. Can cut very small piece (cnc model)

3. Adopts imported industry grade computer system, closed-loop controlled, high precision and quick shift for cutting size.(CNC model)

4. Adopts imported servo motor and ball screw driver mode(CNC model).

5. Optimized function: optimizing to cut according to the working list(CNC model).

6. Tabulation cutting function: several kinds of profiles can be selected quickly.

7. Angle automatic indexing: -45°、90°

$21,400.00

SINON LJRZ2-CNC-550*6000 Double Head CNC Cutting Machine (full automatic, servo-drivers, arbitrary angles)

SINON LJRZ2-CNC-550*6000

DOUBLE HEAD CNC AUTOMATIC CUTTING MACHINE, ARBITRARY ANGLES ADJUST

1. The double head CNC front saw is an advanced equipment used for cutting aluminum profiles.

2. This machine has a neat and stylish appearance, modeled on the European style.

3. The new closed-loop control system used in this machine is highly efficient, ensuring precise cutting.

4. The machine is equipped with a direct drive saw blade, which uses a lever-turn cutting type, making the blade feed by the pneumatic-hydraulic damping cylinder and ensuring smooth cutting.

5. The imported saw blade used in this machine has high precision, making the cutting surface smooth.

6. The cutting angle of the machine can be adjusted in the range of 45°~157.5° by the servo motor driving the speed reducer.

DOUBLE HEAD CNC AUTOMATIC CUTTING MACHINE, ARBITRARY ANGLES ADJUST

1. The double head CNC front saw is an advanced equipment used for cutting aluminum profiles.

2. This machine has a neat and stylish appearance, modeled on the European style.

3. The new closed-loop control system used in this machine is highly efficient, ensuring precise cutting.

4. The machine is equipped with a direct drive saw blade, which uses a lever-turn cutting type, making the blade feed by the pneumatic-hydraulic damping cylinder and ensuring smooth cutting.

5. The imported saw blade used in this machine has high precision, making the cutting surface smooth.

6. The cutting angle of the machine can be adjusted in the range of 45°~157.5° by the servo motor driving the speed reducer.

$56,100.00

copy of SINON SSJ06-CNC-450*3700 Automatic Double Head Cutting Machine

Double head Cutting Machine uPVC

SSJ06-450*3700, Double head vinyl cutting machine for upvc profiles, cutting angle: 90degree, inside 45 and outside 45

SSJ06-450*3700, Double head vinyl cutting machine for upvc profiles, cutting angle: 90degree, inside 45 and outside 45

$21,400.00

SINON LJZ2F-500 Single Head Saw

SINGLE-HEAD BOTTOM FEED SAW

LJZ2F-500 Single-head bottom feed saw for cutting aluminum at various angles. 500mm saw blade. Cutting range 25-155 degrees

MAIN FEATURES

Suitable for door and window profiles, LED lamp frame profiles, curtain wall profiles, etc. Cutting aluminum and PVC profiles. Cutting angle: 25 ° - 155 ° Equipped with a saw blade with a diameter of 500 mm. Equipped with a 3.5m long calibration table and a 4m high profile table. Equipped with a cutting protective screen that automatically lowers when cutting to prevent metal chips from splashing. Horizontal and vertical clamping devices, stable cutting. High precision, high cutting stability, good appearance of the whole machine

LJZ2F-500 Single-head bottom feed saw for cutting aluminum at various angles. 500mm saw blade. Cutting range 25-155 degrees

MAIN FEATURES

Suitable for door and window profiles, LED lamp frame profiles, curtain wall profiles, etc. Cutting aluminum and PVC profiles. Cutting angle: 25 ° - 155 ° Equipped with a saw blade with a diameter of 500 mm. Equipped with a 3.5m long calibration table and a 4m high profile table. Equipped with a cutting protective screen that automatically lowers when cutting to prevent metal chips from splashing. Horizontal and vertical clamping devices, stable cutting. High precision, high cutting stability, good appearance of the whole machine

$10,000.00

SINON LJZ2F-600 Single Head Saw

SINGLE-HEAD SAW WITH BOTTOM FEED SINON LJZ2F-600, 600 MM DISC

JZ2F-600 Automatic single-head saw with bottom feed. Cutting aluminum door and window profiles at an angle of 15-165 degrees. Saw blade diameter 600 mm

Features

1. This automatic single head aluminum profile cutting machine mainly used for cutting aluminum and PVC profiles, with bottom-up saw blade feeding type.

2. This machine is suitable for cutting industrial aluminum and facade profiles, aluminum doors and windows.

3. Equipped with feeding and measuring roller table.

4. The working table is adjustable to increase the cutting area.

JZ2F-600 Automatic single-head saw with bottom feed. Cutting aluminum door and window profiles at an angle of 15-165 degrees. Saw blade diameter 600 mm

Features

1. This automatic single head aluminum profile cutting machine mainly used for cutting aluminum and PVC profiles, with bottom-up saw blade feeding type.

2. This machine is suitable for cutting industrial aluminum and facade profiles, aluminum doors and windows.

3. Equipped with feeding and measuring roller table.

4. The working table is adjustable to increase the cutting area.

$11,100.00

SINON LJJ02A-CNC-500 Automatic CNC Corner Key Cutting Machine

SINON LJJ02A-CNC-500 CNC SERIAL CUTTING SAW

LJJ02A-CNC-500 automatic feed aluminum cutting saw machine. It is a fully automatic CNC machine specially used for cutting corner connectors. The saw blade is made of imported hard alloy, driven by a powerful motor.

LJJ02A-CNC-500 automatic feed aluminum cutting saw machine. It is a fully automatic CNC machine specially used for cutting corner connectors. The saw blade is made of imported hard alloy, driven by a powerful motor.

$14,200.00

SINON SHD01-120 Single Head Welding Machine

SINON SHD01-120

Single Corner PVC Welding Machine

Model: SHD01-120Power Voltage: 220V 50hz 1PhaseInput Power: 1.5 kwWelding Angle: 30°~180°Welding Profile Width: 0-120mmWelding Profile Height: 20-120mmOverall Dimension: 1200x900x1500mmWeight: 300KG

Single Corner PVC Welding Machine

Model: SHD01-120Power Voltage: 220V 50hz 1PhaseInput Power: 1.5 kwWelding Angle: 30°~180°Welding Profile Width: 0-120mmWelding Profile Height: 20-120mmOverall Dimension: 1200x900x1500mmWeight: 300KG

$5,500.00

SINON HJ02-3500.2/2.A Double Head Welding Machine

SINON HJ02-3500.2/2.A Double Head Welding Machine

FEATURES:

● Popular machinery type.

● Various angles welding between 30 to 180 degree is available on last machine head.

● Solid machinery base and structure ensure long life service with high dimension accuracy.

● profile fixture ordered separately can meet various height profiles' processing requirement

● Special profile fixture is easy to change, for high corner strength and later good cleaning

● Each machine head can be working separately or combination

FEATURES:

● Popular machinery type.

● Various angles welding between 30 to 180 degree is available on last machine head.

● Solid machinery base and structure ensure long life service with high dimension accuracy.

● profile fixture ordered separately can meet various height profiles' processing requirement

● Special profile fixture is easy to change, for high corner strength and later good cleaning

● Each machine head can be working separately or combination

$8,500.00

SINON WHJ-3500*2 Double Head Welding Machine (seamless)

SINON WHJ-3500*2 Double Head Welding Machine (seamless)

Model:WHJ-3500*2Power supply 220V 50HZTotal power 3.5KWOperation air pressure 0.6-0.8r/minAir consumption 150L/minWelding profile height 20-120mmWelding profile width 0-120mmWelding range 400*3500mmContour dimension(L*W*H) 4500*1200*1800mmWeight 1000kg

Model:WHJ-3500*2Power supply 220V 50HZTotal power 3.5KWOperation air pressure 0.6-0.8r/minAir consumption 150L/minWelding profile height 20-120mmWelding profile width 0-120mmWelding range 400*3500mmContour dimension(L*W*H) 4500*1200*1800mmWeight 1000kg

$13,900.00

SINON XNSHM01

SINON XNSHM01 PVC SASH ASSEMBLY STATION

This sash hardware installation table is mainly used for the quick assembly of door and window hardware. The automatic window frame centering mechanism and up and down adjustment mechanism make the assembly simple and fast, and greatly improve the work efficiency

This sash hardware installation table is mainly used for the quick assembly of door and window hardware. The automatic window frame centering mechanism and up and down adjustment mechanism make the assembly simple and fast, and greatly improve the work efficiency

$27,500.00

SINON XNSHM02 Sash Hardware Mounting Table with Tripple Drilling

SINON XNSHM02 PVC SASH ASSEMBLY STATION

WITH TRIPPLE DRILLING

This sash hardware installation table is mainly used for the quick assembly of door and window hardware. The automatic window frame centering mechanism and up and down adjustment mechanism make the assembly simple and fast, and greatly improve the work efficiency

WITH TRIPPLE DRILLING

This sash hardware installation table is mainly used for the quick assembly of door and window hardware. The automatic window frame centering mechanism and up and down adjustment mechanism make the assembly simple and fast, and greatly improve the work efficiency

$30,000.00

SINON LJKJ-500 Automatic Notching Saw. 500 mm Blades

ALUMINUM CUTTING SAW SINON LJKJ-500. 500 MM BLADES. SERVO DRIVE

LJKJ-500 Automatic cutting saw for facade profiles Application: this machine is used for processing aluminum facade profiles. The movement of the sawing units is automatic, along the work table with a fixed workpiece. The setting of the cutting angle on each sawing unit is carried out manually, using a special key, on a worm gear. The indicators of the set angles are displayed on two electronic displays.

LJKJ-500 Automatic cutting saw for facade profiles Application: this machine is used for processing aluminum facade profiles. The movement of the sawing units is automatic, along the work table with a fixed workpiece. The setting of the cutting angle on each sawing unit is carried out manually, using a special key, on a worm gear. The indicators of the set angles are displayed on two electronic displays.

$28,900.00

SINON LZJ04-180 Corner Crimping Machine 180 mm (hidraulic)

SINON LZJ04-180 ANGLE CRIMPING MACHINE. 180MM

LZJ04-180. HYDRAULIC ALUMINUM ANGLE CRIMPING MACHINE Total motor power: 3.0 kW Profile processing height: 180 mm Profile width: 100 mm Working pressing force: 80 KN Contour size (L*W*H): 2000×1900×1300 mm Weight: 700 kg

Technical description:

1. The hydraulic aluminum corner crimping machine is not only suitable for the corner assembly of aluminum doors and windows, but also for aluminum curtain walls. When applying pressure, it firmly connects the corners of two aluminum profiles with specially designed wedges.

2. PLC control: The machine is equipped with a programmable logic controller (PLC) for accurate and reliable control. PLC ensures stable operation, and its user-friendly interface simplifies maintenance and operation.

3. Digital display for precise positioning: The main positioning handwheel is equipped with a digital display, ensuring the precise positioning of the machine. This ensures stable and high-quality corner assembly results.

LZJ04-180. HYDRAULIC ALUMINUM ANGLE CRIMPING MACHINE Total motor power: 3.0 kW Profile processing height: 180 mm Profile width: 100 mm Working pressing force: 80 KN Contour size (L*W*H): 2000×1900×1300 mm Weight: 700 kg

Technical description:

1. The hydraulic aluminum corner crimping machine is not only suitable for the corner assembly of aluminum doors and windows, but also for aluminum curtain walls. When applying pressure, it firmly connects the corners of two aluminum profiles with specially designed wedges.

2. PLC control: The machine is equipped with a programmable logic controller (PLC) for accurate and reliable control. PLC ensures stable operation, and its user-friendly interface simplifies maintenance and operation.

3. Digital display for precise positioning: The main positioning handwheel is equipped with a digital display, ensuring the precise positioning of the machine. This ensures stable and high-quality corner assembly results.

$11,600.00

SINON LZJ03-130 Corner Crimping Machine, 130 mm

LZJ03-130 CORNER CRIMPING MACHINE. 130MM

LZJ03-130. Angle crimping press for aluminum profiles, suitable for all kinds of aluminum alloy doors and windows, including thermal break profiles and ordinary aluminum profiles

Main Features

Universal corner crimping machine for aluminum profiles. The hydraulic system has the advantages of high power, wide range of profiles and stable operation. It is suitable for the production of all aluminum doors and windows.

Pneumatic compression in the vertical direction can easily adjust the position. It is suitable for any series of profiles and greatly improves the flatness of the group angle.

The foot switch control can step-by-step control the positioning and grouping of the inclination angle.

The standard set includes three corner knives of different thickness, which can be combined as desired and are suitable for different profiles. (The knife can be adjusted depending on the profile)

LZJ03-130. Angle crimping press for aluminum profiles, suitable for all kinds of aluminum alloy doors and windows, including thermal break profiles and ordinary aluminum profiles

Main Features

Universal corner crimping machine for aluminum profiles. The hydraulic system has the advantages of high power, wide range of profiles and stable operation. It is suitable for the production of all aluminum doors and windows.

Pneumatic compression in the vertical direction can easily adjust the position. It is suitable for any series of profiles and greatly improves the flatness of the group angle.

The foot switch control can step-by-step control the positioning and grouping of the inclination angle.

The standard set includes three corner knives of different thickness, which can be combined as desired and are suitable for different profiles. (The knife can be adjusted depending on the profile)

$6,500.00

SINON SCX03-3*60 Water Slot Milling Machine

SINON SCX03-3*60 Automatic Water Drainage Milling Machine

Main feature:

1. It is one of the PVC window processing machines, which is used to mill water drainage holes.

2. Full structure with high rigidity, processing beautiful water grooves, high processing quality.

3. Automatic change of cutters on the lower head, one-time fixation to complete the processing of water grooves.

4. High efficiency, suitable for mass production.

5. Special feeding system, no special maintenance, high milling quality.

6. Simple adjustment of the cutter position to process different profiles.

7. The milling length of water grooves is adjustable within 100mm, wide adaptability.

8. Adopt linear motion of the bearing to ensure the processing accuracy.

Main feature:

1. It is one of the PVC window processing machines, which is used to mill water drainage holes.

2. Full structure with high rigidity, processing beautiful water grooves, high processing quality.

3. Automatic change of cutters on the lower head, one-time fixation to complete the processing of water grooves.

4. High efficiency, suitable for mass production.

5. Special feeding system, no special maintenance, high milling quality.

6. Simple adjustment of the cutter position to process different profiles.

7. The milling length of water grooves is adjustable within 100mm, wide adaptability.

8. Adopt linear motion of the bearing to ensure the processing accuracy.

$4,200.00

SINON JQK6-CNC-120 CNC Corner Cleaning Machine (6 tools)

JQK6-CNC-120 CNC PVC WINDOW CLEANING MACHINE (6 TOOLS)

1. CNC machine used to clean the welding slag in the corners of the window frame and sash at 90°.

2. Can process the outer corner, the upper and lower part of the corner surface, the inner corner sealing rubber groove and the inner plane of the casement window, the sealing groove of the outer corner of the casement window, the inner corner joint of the sliding window.

3. Six CNC corner cleaning tools control the process flow, simplifying the operation.

4. This machine has the function of compensating the corner arches.

5. The machine can store more than 100 profile processing programs.

6. According to the conditions on the site, the values are randomly dialed, and the processing program is adjusted so that the weld seams with deviations due to the dimensional accuracy of the profiles can be effectively cleaned.

1. CNC machine used to clean the welding slag in the corners of the window frame and sash at 90°.

2. Can process the outer corner, the upper and lower part of the corner surface, the inner corner sealing rubber groove and the inner plane of the casement window, the sealing groove of the outer corner of the casement window, the inner corner joint of the sliding window.

3. Six CNC corner cleaning tools control the process flow, simplifying the operation.

4. This machine has the function of compensating the corner arches.

5. The machine can store more than 100 profile processing programs.

6. According to the conditions on the site, the values are randomly dialed, and the processing program is adjusted so that the weld seams with deviations due to the dimensional accuracy of the profiles can be effectively cleaned.

$23,200.00

SINON JQK9-CNC-130 CNC Corner Cleaning Machine (9 tools)

JQK9-CNC-130 CNC PVC WINDOW CLEANING MACHINE (9 TOOLS)

1. CNC machine used to clean the welding slag in the corners of the window frame and sash at 90°.

2. Can process the outer corner, the upper and lower part of the corner surface, the inner corner sealing rubber groove and the inner plane of the casement window, the sealing groove of the outer corner of the casement window, the inner corner joint of the sliding window.

3. Six CNC corner cleaning tools control the process flow, simplifying the operation.

4. This machine has the function of compensating the corner arches.

5. The machine can store more than 100 profile processing programs.

6. According to the conditions on the site, the values are randomly dialed, and the processing program is adjusted so that the weld seams with deviations due to the dimensional accuracy of the profiles can be effectively cleaned.

1. CNC machine used to clean the welding slag in the corners of the window frame and sash at 90°.

2. Can process the outer corner, the upper and lower part of the corner surface, the inner corner sealing rubber groove and the inner plane of the casement window, the sealing groove of the outer corner of the casement window, the inner corner joint of the sliding window.

3. Six CNC corner cleaning tools control the process flow, simplifying the operation.

4. This machine has the function of compensating the corner arches.

5. The machine can store more than 100 profile processing programs.

6. According to the conditions on the site, the values are randomly dialed, and the processing program is adjusted so that the weld seams with deviations due to the dimensional accuracy of the profiles can be effectively cleaned.

$27,200.00

SINON LDJZ1-120 Pneumatic Screw Driver

SINON LDJZ1-120 Pneumatic Screw Driver

LDJZ1-120 is used for fastening the Reinforcement of the PVC window and door /

PLC control system, France Schneider system

FEATURES:

● This machine used for fastening the Reinforcement of the PVC window and door.

● Adopt PLC programming controller, it’s reliable and stably.

● The machine head is adjustable from front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

● Auto feeding and distributing screws by special feeding device, with without screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory.

● With standard two sets of 2M supporting bracket.

LDJZ1-120 is used for fastening the Reinforcement of the PVC window and door /

PLC control system, France Schneider system

FEATURES:

● This machine used for fastening the Reinforcement of the PVC window and door.

● Adopt PLC programming controller, it’s reliable and stably.

● The machine head is adjustable from front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

● Auto feeding and distributing screws by special feeding device, with without screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory.

● With standard two sets of 2M supporting bracket.

$5,200.00

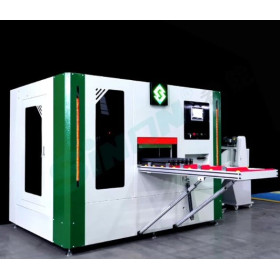

LJKJ-CNC-600 CNC Notching Saw Aluminium

For the first time in Russia. New model of CNC Facade Notching Saw.

Manufactured by SINON, China.

High-quality equipment from an authorized dealer in Russia.

We deliver to order.

Model LJKJ-CNC-600. CNC machine, single 600 mm diameter saw blade, cooling, 180-degree blade rotation. Extensive library of possible notching options. Any non-standard façade profile notches. High blade movement and rotation speed. The portal moves in three axes, and the blade angle is adjusted automatically. The work table can also be rotated to the desired angle, with the set angle displayed on the electronic display.

Delivery time is 3-4 months. We work with VAT under contract. Import into Russia is completely legal, official delivery, no gray areas. Reliable, efficient, and safe. We have been operating in the Russian market for over 20 years.

The price of the equipment includes delivery to the client, commissioning work, and training of personnel to operate the equipment.

Manufactured by SINON, China.

High-quality equipment from an authorized dealer in Russia.

We deliver to order.

Model LJKJ-CNC-600. CNC machine, single 600 mm diameter saw blade, cooling, 180-degree blade rotation. Extensive library of possible notching options. Any non-standard façade profile notches. High blade movement and rotation speed. The portal moves in three axes, and the blade angle is adjusted automatically. The work table can also be rotated to the desired angle, with the set angle displayed on the electronic display.

Delivery time is 3-4 months. We work with VAT under contract. Import into Russia is completely legal, official delivery, no gray areas. Reliable, efficient, and safe. We have been operating in the Russian market for over 20 years.

The price of the equipment includes delivery to the client, commissioning work, and training of personnel to operate the equipment.

$50,500.00

SZA-400 ULTRA 5-Axis CNC End Milling Machine

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

$31,800.00