FENSTEK & SINON, CHINA (UPVC & ALUM MACHINES)

There are 12 products.

FENSTEK ADDSE-2

ADSSE2 UPVC Window & Door Auto Screw Driver Machine Feature:

1. Auto screw driver machine ADSSE2 is a stationary Screwdriver Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e.g.to fix the reinforcement in PVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate.

4. Constant screw driving depth for all materials and independent lf the work piece height due to the automatic depth of drive control.

5. Simple Operation: Manual operation by treadle

6. High Efficiency: Screw driving cycle time to insert one self-drillng screw for reinforcement fixing approx.2 seconds.

7. Horizontal clamping device.

1. Auto screw driver machine ADSSE2 is a stationary Screwdriver Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e.g.to fix the reinforcement in PVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate.

4. Constant screw driving depth for all materials and independent lf the work piece height due to the automatic depth of drive control.

5. Simple Operation: Manual operation by treadle

6. High Efficiency: Screw driving cycle time to insert one self-drillng screw for reinforcement fixing approx.2 seconds.

7. Horizontal clamping device.

$11,250.00

FENSTEK ADS500*4300 Double Head Cutting Machine (automatic)

ADS500x4300 Aluminum Window CNC Double Head Cutting Saw

Features:

1.The main material for aluminum alloy curtain wall, window material cutting and can also be used for plastic profile cutting.

2.The use of carbide saw blades, diameter up to 500 dia, line of high speed high precision machining.

3.Right heads feeding adopts pitch ball screw-lead motion, with high accurate driving, locating and smooth working.

4.This machine uses the numerical control technology, profiles of different specifications can completed automatically under the expected size.

5.Machine during operation, two saw blade can separate cutting.

6.The blade from the bottom to the top, sawing profile is more safe and reliable, and the cutting height and cutting width are large.

Features:

1.The main material for aluminum alloy curtain wall, window material cutting and can also be used for plastic profile cutting.

2.The use of carbide saw blades, diameter up to 500 dia, line of high speed high precision machining.

3.Right heads feeding adopts pitch ball screw-lead motion, with high accurate driving, locating and smooth working.

4.This machine uses the numerical control technology, profiles of different specifications can completed automatically under the expected size.

5.Machine during operation, two saw blade can separate cutting.

6.The blade from the bottom to the top, sawing profile is more safe and reliable, and the cutting height and cutting width are large.

$31,200.00

FENSTEK TADS600*6000 Double Head 3-Axis Saw (Arbitrary Angles, Tilting&Pivoting Option)

TADS600X6000

Aluminum Window CNC Double Head Cutting Saw

Features:

1. The machine adopts high carbon steel welding and tempering, and the main structural parts use ductile cast iron integrated molding to ensure the accuracy and durability of the machine.

2. This machine is mainly used in doors and Windows curtain wall or industrial profile composite any corner cutting.

3. Workbench rotation angle of 22.5° ~140, Saw blade fillet range -45°~90°

4. The damping method is adopted to ensure that the incoming knife is stable and fast retreat, and the knife is avoided from shaking during the use process.

5. The maximum outer diameter of diamond saw blade up to 600mm, high line speed, high machining precision

6. The high precision servo electric cylinder drive for rotation and length positioning is servo and closed loop.

Aluminum Window CNC Double Head Cutting Saw

Features:

1. The machine adopts high carbon steel welding and tempering, and the main structural parts use ductile cast iron integrated molding to ensure the accuracy and durability of the machine.

2. This machine is mainly used in doors and Windows curtain wall or industrial profile composite any corner cutting.

3. Workbench rotation angle of 22.5° ~140, Saw blade fillet range -45°~90°

4. The damping method is adopted to ensure that the incoming knife is stable and fast retreat, and the knife is avoided from shaking during the use process.

5. The maximum outer diameter of diamond saw blade up to 600mm, high line speed, high machining precision

6. The high precision servo electric cylinder drive for rotation and length positioning is servo and closed loop.

$100,500.00

FENSTEK LJB2B CNC 600*6000 Double Head CNC Arbitr

FENSTEK LJB2B-CNC-600*6000 CNC B2B TWO-HEAD FRONT SAW WITH SERVO DRIVE

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial computer, label printer installed. 600 mm disks, cooling. Maximum cutting length 6000 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 22.5 ° - 135 °.

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial computer, label printer installed. 600 mm disks, cooling. Maximum cutting length 6000 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 22.5 ° - 135 °.

$84,350.00

ПВХ FENSTEK IADS500*4500 Double Head CNC Cutting Machine

PVC FENSTEK IADS500*4500 TWO-HEAD CNC SAW FOR CUTTING 4-6 PVC PROFILES IN ONE CYCLE

SUPPLY ON ORDER!!!

IADS500X4500 Automatic Double-Head Saw for Cutting PVC Profiles with Bottom Feed. CNC Saw for Cutting 4-6 Profiles at a Time. It is possible to retrofit the saw with an industrial computer and label printer option.

Characteristics:

1. The machine is specially designed for cutting PVC window profiles in large volumes.

2. Four or six parts can be cut at a time, depending on the profile width.

3. Automatic change inside 45 and 90 degrees. Different degrees are not available.

4. The saw blade is fed stably and accurately from the inside to the outside using a pneumatic cylinder. An additional hydropneumatic feed cylinder is available.

SUPPLY ON ORDER!!!

IADS500X4500 Automatic Double-Head Saw for Cutting PVC Profiles with Bottom Feed. CNC Saw for Cutting 4-6 Profiles at a Time. It is possible to retrofit the saw with an industrial computer and label printer option.

Characteristics:

1. The machine is specially designed for cutting PVC window profiles in large volumes.

2. Four or six parts can be cut at a time, depending on the profile width.

3. Automatic change inside 45 and 90 degrees. Different degrees are not available.

4. The saw blade is fed stably and accurately from the inside to the outside using a pneumatic cylinder. An additional hydropneumatic feed cylinder is available.

$52,500.00

FENSTEK AGBS3000 Automatic Glass Bead Cutting Machine

FENSTEK AGBS3000 Automatic Glass Bead Cutting Machine

UPVC Window CNC Glazing Bead Saw

Features:

1.Automatic 45 degree cutting u-PVC glazing bead profile.

2.Two glazing bead cutting in one time.

3.Automatic saw blade feeding by pneumatic cylinder and moving on precise rod.

4.4 pieces saw blade ensure precise cutting, Double cutting one each end to mill the hook foot.

5.Vertical clamping device and special designed cutting jig ensure stable positioning.

6.Two hand safety operation

7.Friendly using measuring rod.

8.Precise & easy operated measuring table (Only for GBST1800)

UPVC Window CNC Glazing Bead Saw

Features:

1.Automatic 45 degree cutting u-PVC glazing bead profile.

2.Two glazing bead cutting in one time.

3.Automatic saw blade feeding by pneumatic cylinder and moving on precise rod.

4.4 pieces saw blade ensure precise cutting, Double cutting one each end to mill the hook foot.

5.Vertical clamping device and special designed cutting jig ensure stable positioning.

6.Two hand safety operation

7.Friendly using measuring rod.

8.Precise & easy operated measuring table (Only for GBST1800)

$17,500.00

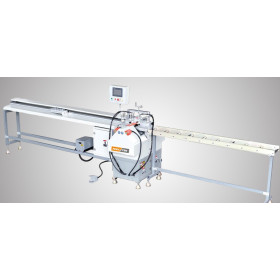

FENSTEK AGBS350 CNC ALU Glass Bead Cutting Machine

AGBS350 Aluminum Window CNC Glazing Bead Cutting Saw

Features:

1. This glazing bead saw is suitable for cutting aluminium glazing bead at 90 degree.

2. Equipped with portable wireless measuring system. Precise and easy measuring.

3. High precision spindle saw blade motor, stable performance.

4. The machine adopts square rail, imported gear rack drive, speedy and high repeat positioning accuracy.

5. Schneider PLC, Servo motor and Schneider servo driver assure long time & stable running.

6. Excellent processing accuracy 0. 1mm

Features:

1. This glazing bead saw is suitable for cutting aluminium glazing bead at 90 degree.

2. Equipped with portable wireless measuring system. Precise and easy measuring.

3. High precision spindle saw blade motor, stable performance.

4. The machine adopts square rail, imported gear rack drive, speedy and high repeat positioning accuracy.

5. Schneider PLC, Servo motor and Schneider servo driver assure long time & stable running.

6. Excellent processing accuracy 0. 1mm

$28,900.00

FENSTEK ASD-6000 Industrial Screw Driver with Drilling Option

ASD-6000

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

$86,700.00

FENSTEK ADDSE Single Head Industrial Screw Driver

ADSSE Auto Screw Driver Machine for UPVC Window Features:

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

$6,500.00

FENSTEK ADS600*4500 Double Head CNC Arbitrary Angle Saw

FENSTEK ADS600*4500 CNC B2B TWO-HEAD FRONT SAW WITH SERVO DRIVE

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

$63,600.00

FENSTEK ADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$33,000.00

FENSTEK IADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$43,500.00