Главная

There are 45 products.

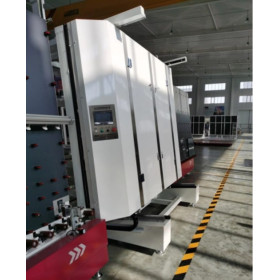

KLVS 2025 IG Line 2,0 m

KLVS2025

AUTOMATIC VERTICAL GLASS ASSEMBLY LINE,

WITH FLAT PRESS.

GLASS ASSEMBLY INSIDE THE PRESS OR AT THE AUTOMATIC ASSEMBLY STATION.

Working height 2.0 m

LINE DESCRIPTION

1. External or internal assembly program, complex function

2. Automatic glass unit production line with numerical control, automatic LOW-E identification

3. Siemens PLC control. Touch screen human-machine interface

4. Using imported vacuum generator and suction cup, resulting in perfect glass suction effect

5. Producing step glass and triple glass according to different customer requirements

6. Automatically adjust the speed of variable frequency in the whole distance, which can save the waiting time of operation and improve production efficiency.

AUTOMATIC VERTICAL GLASS ASSEMBLY LINE,

WITH FLAT PRESS.

GLASS ASSEMBLY INSIDE THE PRESS OR AT THE AUTOMATIC ASSEMBLY STATION.

Working height 2.0 m

LINE DESCRIPTION

1. External or internal assembly program, complex function

2. Automatic glass unit production line with numerical control, automatic LOW-E identification

3. Siemens PLC control. Touch screen human-machine interface

4. Using imported vacuum generator and suction cup, resulting in perfect glass suction effect

5. Producing step glass and triple glass according to different customer requirements

6. Automatically adjust the speed of variable frequency in the whole distance, which can save the waiting time of operation and improve production efficiency.

$70,000.00

KLVS 2536 IG LINE 2,5 m

KLVS2536

AUTOMATIC VERTICAL GLASS ASSEMBLY LINE,

WITH FLAT PRESS.

GLASS ASSEMBLY INSIDE THE PRESS OR AT THE AUTOMATIC ASSEMBLY STATION.

Working height 2.5 m.

LINE DESCRIPTION

1. External or internal assembly program, comprehensive function

2. Automatic insulating glass production line with numerical control, LOW-E automatic identification

3. Siemens PLC control. Human-machine interface touch screen

4. Using imported vacuum generator and suction cup, led to the ideal glass sucking effect

5. Producing stepped (structural) insulating glass and triple glass according to different customer requests

6. Automatic variable frequency speed adjustment in the whole distance, which can save the waiting time of operation and improve the production efficiency.

AUTOMATIC VERTICAL GLASS ASSEMBLY LINE,

WITH FLAT PRESS.

GLASS ASSEMBLY INSIDE THE PRESS OR AT THE AUTOMATIC ASSEMBLY STATION.

Working height 2.5 m.

LINE DESCRIPTION

1. External or internal assembly program, comprehensive function

2. Automatic insulating glass production line with numerical control, LOW-E automatic identification

3. Siemens PLC control. Human-machine interface touch screen

4. Using imported vacuum generator and suction cup, led to the ideal glass sucking effect

5. Producing stepped (structural) insulating glass and triple glass according to different customer requests

6. Automatic variable frequency speed adjustment in the whole distance, which can save the waiting time of operation and improve the production efficiency.

$81,000.00

ZNJ2025-1(2) IG Sealing Robot

ZNJ2025-1 or ZNJ2025-2

AUTOMATIC INSULATING GLASS SEALING ROBOT

ONE OR TWO EXTRUSION GROUPS (upon customer's request)

CNC Insulating Glass Sealing Robot

MACHINE DESCRIPTION

1. High sealing performance, high automation, lower labor cost, save labor cost, improve production efficiency

2. Fully intelligent and smart HMI on touch screen with memory function and easy operation

3. Better sealing quality without air bubbles, smooth surface, no need to adjust the angles after applying the sealant (polysulfide or silicone).

4. For ZNJ2025-2 model: optional use of two sealant supply systems, quick changeover and one-button operation. You can either use two different sealants or alternate pump groups when changing tanks.

AUTOMATIC INSULATING GLASS SEALING ROBOT

ONE OR TWO EXTRUSION GROUPS (upon customer's request)

CNC Insulating Glass Sealing Robot

MACHINE DESCRIPTION

1. High sealing performance, high automation, lower labor cost, save labor cost, improve production efficiency

2. Fully intelligent and smart HMI on touch screen with memory function and easy operation

3. Better sealing quality without air bubbles, smooth surface, no need to adjust the angles after applying the sealant (polysulfide or silicone).

4. For ZNJ2025-2 model: optional use of two sealant supply systems, quick changeover and one-button operation. You can either use two different sealants or alternate pump groups when changing tanks.

$73,000.00

ZNJ2540-1(2) IG Sealing Robot

ZNJ2540-1 or ZNJ2540-2

AUTOMATIC INSULATING GLASS SEALING ROBOT

ONE OR TWO EXTRUSION GROUPS (upon customer's request)

CNC Insulating Glass Sealing Robot

MACHINE DESCRIPTION

1. High sealing performance, high automation, lower labor cost, save labor cost, improve production efficiency

2. Fully intelligent and smart HMI on touch screen with memory function and easy operation

3. Better sealing quality without air bubbles, smooth surface, no need to adjust the angles after applying the sealant (polysulfide or silicone).

4. For ZNJ2540-2 model: optional use of two sealant supply systems, quick changeover and one-button operation. You can either use two different sealants or alternate pump groups when changing tanks.

AUTOMATIC INSULATING GLASS SEALING ROBOT

ONE OR TWO EXTRUSION GROUPS (upon customer's request)

CNC Insulating Glass Sealing Robot

MACHINE DESCRIPTION

1. High sealing performance, high automation, lower labor cost, save labor cost, improve production efficiency

2. Fully intelligent and smart HMI on touch screen with memory function and easy operation

3. Better sealing quality without air bubbles, smooth surface, no need to adjust the angles after applying the sealant (polysulfide or silicone).

4. For ZNJ2540-2 model: optional use of two sealant supply systems, quick changeover and one-button operation. You can either use two different sealants or alternate pump groups when changing tanks.

$78,500.00

BTM-02 Butyl Extruder Semi-Automatic

BTM02

SEMI-AUTOMATIC BUTYL EXTRUDER.

Manual adjustment of spacer frame width, manual lifting of butyl tank for replacement

Butyl sealant spraying machine

1. The whole structure is modular, low failure rate and easy maintenance.

The frame, guide rail, belt and sealant nozzle are parallel to each other, ensuring stable operation

2. Adopt advanced pneumatic-hydraulic pressure boosting technology to ensure stable sealant coating

3. Touch screen temperature control, high accuracy, easy operation.

4. 5-step conveying speed adjustment

5. Real-time display of sealant volume, pre-warning.

SEMI-AUTOMATIC BUTYL EXTRUDER.

Manual adjustment of spacer frame width, manual lifting of butyl tank for replacement

Butyl sealant spraying machine

1. The whole structure is modular, low failure rate and easy maintenance.

The frame, guide rail, belt and sealant nozzle are parallel to each other, ensuring stable operation

2. Adopt advanced pneumatic-hydraulic pressure boosting technology to ensure stable sealant coating

3. Touch screen temperature control, high accuracy, easy operation.

4. 5-step conveying speed adjustment

5. Real-time display of sealant volume, pre-warning.

$18,600.00

DJJ-06 Automatic Butyl Extruder

DJJ06 BUTYL EXTRUDER AUTOMATIC.

Automatic adjustment of spacer width, pneumatic lifting of butyl tank for replacement

Butyl sealant spraying machine

1. The whole structure is modular, low failure rate and easy maintenance.

The frame, guide rail, belt and sealant nozzle are parallel to each other, ensuring stable operation

2. Adopt advanced pneumatic-hydraulic pressure injection technology to ensure stable sealant coating

3. Touch screen temperature control, high accuracy, easy operation.

4. 5-step conveying speed adjustment

5. Real-time display of sealant volume, pre-warning.

6. The width of the sealant nozzle is automatically adjusted and quickly positioned. Automatic adjustment of the spacer width.

Automatic adjustment of spacer width, pneumatic lifting of butyl tank for replacement

Butyl sealant spraying machine

1. The whole structure is modular, low failure rate and easy maintenance.

The frame, guide rail, belt and sealant nozzle are parallel to each other, ensuring stable operation

2. Adopt advanced pneumatic-hydraulic pressure injection technology to ensure stable sealant coating

3. Touch screen temperature control, high accuracy, easy operation.

4. 5-step conveying speed adjustment

5. Real-time display of sealant volume, pre-warning.

6. The width of the sealant nozzle is automatically adjusted and quickly positioned. Automatic adjustment of the spacer width.

$21,000.00

BST-03 Двухкомпонентый экструдер

BST-03 Two-component sealant extruder

EXTRUDER DESCRIPTION

1. Suitable for mass production of insulating glass and curtain wall.

2. Pneumatic control, easy to operate

3. The main and auxiliary motors adopt American advanced technology, stable power, large sealant output

4. Integrated structure of base material pump, hardener pump and metering pump, prevent sealant leakage

5. Special device in base material pump and hardener pump, prevent idle running

6. Special check valve in metering pump, so that the sealant comes out more smoothly, suitable for all kinds of sealants. prevent incomplete mixing

EXTRUDER DESCRIPTION

1. Suitable for mass production of insulating glass and curtain wall.

2. Pneumatic control, easy to operate

3. The main and auxiliary motors adopt American advanced technology, stable power, large sealant output

4. Integrated structure of base material pump, hardener pump and metering pump, prevent sealant leakage

5. Special device in base material pump and hardener pump, prevent idle running

6. Special check valve in metering pump, so that the sealant comes out more smoothly, suitable for all kinds of sealants. prevent incomplete mixing

$19,000.00

XPJ-4 Glass Vacuum Lifter

XPJ-4 Vacuum lifting device for transferring assembled glass units from the output station of the assembly line to the storage pyramid.

Max. weight: 300 kg

Left-right rotation angle: 90

Column height: 3400 mm

Track length: 3000 mm

Vertical up/down: 1000 mm

Suction cups: 4

Air pressure: 0.5 MPa~0.8 MPa

Max. weight: 300 kg

Left-right rotation angle: 90

Column height: 3400 mm

Track length: 3000 mm

Vertical up/down: 1000 mm

Suction cups: 4

Air pressure: 0.5 MPa~0.8 MPa

$5,300.00

APJ-6 Automatic Vacuum Glass Lifter

AUTOMATIC VACUUM LIFT FOR GLASS UNITS

It is designed not only for moving glass units inside the production area, but is also designed for work at construction sites for moving and feeding finished glass units into the installation opening area.

APJ-6 AUTOMATIC VACUUM LIFT FOR GLASS UNITS

Loading capacity 600 kg, standard equipment - 6 vacuum suction cups, electric lifting, electric telescopic system, electric turning, electric lateral movement, manual rotation and manual lateral rotation.

Optional equipment, in addition to the standard - electric rotation, electric lateral rotation and wireless remote control.

It is designed not only for moving glass units inside the production area, but is also designed for work at construction sites for moving and feeding finished glass units into the installation opening area.

APJ-6 AUTOMATIC VACUUM LIFT FOR GLASS UNITS

Loading capacity 600 kg, standard equipment - 6 vacuum suction cups, electric lifting, electric telescopic system, electric turning, electric lateral movement, manual rotation and manual lateral rotation.

Optional equipment, in addition to the standard - electric rotation, electric lateral rotation and wireless remote control.

$30,000.00

APJ-4 Automatic Vacuum Lifter

AUTOMATIC VACUUM LIFT FOR GLASS UNITS

It is designed not only for moving glass units inside the production area, but is also designed for work at construction sites for moving and feeding finished glass units into the installation opening area.

APJ-4 AUTOMATIC VACUUM LIFT FOR GLASS UNITS

Loading capacity 300 kg, standard equipment - 4 vacuum suction cups, electric lifting, electric telescopic system, electric turning, electric lateral movement, manual rotation and manual lateral rotation.

Optional equipment, in addition to the standard - electric rotation, electric lateral rotation and wireless remote control.

$29,000.00

LZJ02 Aluminium Spacer Bending Machine

LZJ02 Aluminium Spacer Bending Machine

1. All operations can be finished on touch screen ,easy to operate

2. Can set 4 kinds specifications ,32 kinds size glass data ,and can continue to process

9999 pcs for each size ,the machine can calculate the aluminium frame size according to

glass size .

3. Adopt servo control feeding system ,the precision of the aluminium frame van be

0.1mm/m

4. Adopt numerical control bending system ,the precision can be 0.1°

5. Without waste any aluminium spacer

6. 4 storage slots to store 4 kinds aluminium spacer

1. All operations can be finished on touch screen ,easy to operate

2. Can set 4 kinds specifications ,32 kinds size glass data ,and can continue to process

9999 pcs for each size ,the machine can calculate the aluminium frame size according to

glass size .

3. Adopt servo control feeding system ,the precision of the aluminium frame van be

0.1mm/m

4. Adopt numerical control bending system ,the precision can be 0.1°

5. Without waste any aluminium spacer

6. 4 storage slots to store 4 kinds aluminium spacer

$40,000.00

FZS 02 Automatic Desiccant Filling Machine

FZS 02 Automatic desiccant filling machine

1.Germany Siemens PLC Control System

2.Touching Screen Interface, Simple and Visible

3.Fill for Bendable Frame and Connectable Frame

4.Auto Desiccant Loading Function

5.Filling Time can be Adjusted

6.Auto drilling, Filling and Sealing Function

1.Germany Siemens PLC Control System

2.Touching Screen Interface, Simple and Visible

3.Fill for Bendable Frame and Connectable Frame

4.Auto Desiccant Loading Function

5.Filling Time can be Adjusted

6.Auto drilling, Filling and Sealing Function

$15,000.00

SSJ-01 Automatic Aluminium Frame Conveyor

SSJ-01

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

$3,600.00

YILMAZ ALM 6510 Cutting&Milling Center Aluminium

ALM 6510 is 8-axis CNC controlled machining center which is specifically designed to process any kind of aluminium profiles in the market. The machine can do all operations on four sides of aluminium profiles such as milling, opening key holes, hinge holes, handle holes, marking, saw blade cutting etc. ALM 6510 has the programming feature which provides minimum waste and maximum amount of production. 7 pieces of aluminium profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. The cutting unit can perform serial cutting of profiles in the range of 45⁰-135°. Operator attaches barcodes on the processed profiles to make them ready for crimping operation.

$0.00

YILMAZ AIM 3410 4-Axis Machining Center

AIM 3410 is a 4-axis CNC machine designed specifically for processing all types of aluminum and PVC profiles, low carbon alloys and thin-walled steel profiles available in the market. Thanks to the 4th axis function, it can also machine 3 profile surfaces. Quick tool changes are ensured by a mobile in-line magazine equipped with 8 standard tools. To minimize tool change time, the tool magazine was designed on the moving Y axis of the machine.

$0.00

YILMAZ AIM 7510 CNC Machining Center 5-Axis

AIM 7510 is 5-axis servo-controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminium & PVC profiles, light alloys in general and thin walled steel profiles.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

$0.00

YILMAZ AIM 4420 / 7420 CNC Machining Center 4-Axis

YILMAZ AIM 4420 / 7420 4-AXIS MACHINING CENTER FOR ALUMINUM PROFILES

AIM 4420-7420 is a 4-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles, as well as low-carbon, thin-walled steel profiles used in the market. AIM 4420 : 4 m. - AIM 7420: 7 m.

PRICE ON REQUEST

AIM 4420-7420 is a 4-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles, as well as low-carbon, thin-walled steel profiles used in the market. AIM 4420 : 4 m. - AIM 7420: 7 m.

PRICE ON REQUEST

$0.00

YILMAZ DC421 PBS Double Head Automatic Saw

YILMAZ_DC421 PBS TWO-HEAD AUTOMATIC SAW

DC 421PBS. Two-head saw with Windows, printer and data exchange interface. Frontal saw blade feed, with cooling.

DC 421 PBS is a fully automatic sawing machine that is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminium materials by means of double head sawing units equipped with Ø 420 mm of saw blades

DC 421PBS. Two-head saw with Windows, printer and data exchange interface. Frontal saw blade feed, with cooling.

DC 421 PBS is a fully automatic sawing machine that is designed for the strait or angular cutting operations of large size of profiles made of PVC and aluminium materials by means of double head sawing units equipped with Ø 420 mm of saw blades

$0.00

YILMAZ CDC600 CNC Double Head Cutting Machine (Tilting&Pivoting Options)

YILMAZ CDC600 TWO-HEAD AUTOMATIC CNC SAW

YILMAZ CDC600 automatic double-head CNC saw for cutting large PVC and aluminum profiles, straight or at an angle with a Ø 600 mm double-head saw. Saw blade feed from below.

The CDC 600 is a fully automatic machine designed for cutting large PVC and aluminum profiles straight or at an angle with a Ø 600 mm double-head saw. It provides optimum cutting performance in a variety of cutting situations thanks to its large-diameter saw and the rotary-tilt cutting mechanism from below. The left cutting unit is stationary, while the movable right cutting unit automatically switches to measurement. This is a great advantage for the user, as it allows for special angle cuts without having to calculate when performing point-to-point cutting operations.

YILMAZ CDC600 automatic double-head CNC saw for cutting large PVC and aluminum profiles, straight or at an angle with a Ø 600 mm double-head saw. Saw blade feed from below.

The CDC 600 is a fully automatic machine designed for cutting large PVC and aluminum profiles straight or at an angle with a Ø 600 mm double-head saw. It provides optimum cutting performance in a variety of cutting situations thanks to its large-diameter saw and the rotary-tilt cutting mechanism from below. The left cutting unit is stationary, while the movable right cutting unit automatically switches to measurement. This is a great advantage for the user, as it allows for special angle cuts without having to calculate when performing point-to-point cutting operations.

$0.00

YILMAZ KD402S Double Head Cutting Machine

YILMAZ KD 402 S TWO-HEAD SAW FOR CUTTING PVC AND ALUMINUM PROFILES

TWO-HEAD SEMI-AUTOMATIC PENDULUM SAW YILMAZ KD402PS

Designed for two- and one-sided cutting of PVC and AL profiles. Possible main cutting angles are 15°, 22.5°, 30°, 45°, 90° and intermediate. Maximum cross-section of the workpiece: at 90° - 205x125 mm; 175x138 mm or at 45° - 145x125 mm; 125x138 mm. Hydropneumatic disc feed. Clamps and pneumatic braking system. Adjustable cutting speed. The left head is fixed, the right one is manually moved. Included: 2x400 mm saw blades, blow gun.

TWO-HEAD SEMI-AUTOMATIC PENDULUM SAW YILMAZ KD402PS

Designed for two- and one-sided cutting of PVC and AL profiles. Possible main cutting angles are 15°, 22.5°, 30°, 45°, 90° and intermediate. Maximum cross-section of the workpiece: at 90° - 205x125 mm; 175x138 mm or at 45° - 145x125 mm; 125x138 mm. Hydropneumatic disc feed. Clamps and pneumatic braking system. Adjustable cutting speed. The left head is fixed, the right one is manually moved. Included: 2x400 mm saw blades, blow gun.

$0.00