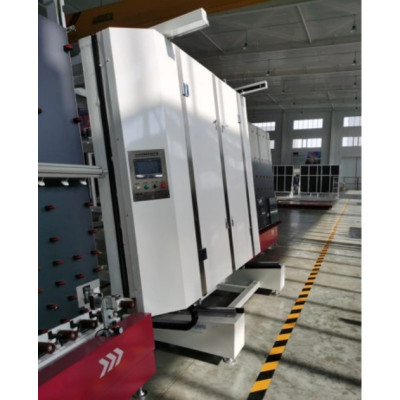

KLVS 2536 IG LINE 2,5 m

KLVS2536

AUTOMATIC VERTICAL GLASS ASSEMBLY LINE,

WITH FLAT PRESS.

GLASS ASSEMBLY INSIDE THE PRESS OR AT THE AUTOMATIC ASSEMBLY STATION.

Working height 2.5 m.

LINE DESCRIPTION

1. External or internal assembly program, comprehensive function

2. Automatic insulating glass production line with numerical control, LOW-E automatic identification

3. Siemens PLC control. Human-machine interface touch screen

4. Using imported vacuum generator and suction cup, led to the ideal glass sucking effect

5. Producing stepped (structural) insulating glass and triple glass according to different customer requests

6. Automatic variable frequency speed adjustment in the whole distance, which can save the waiting time of operation and improve the production efficiency.

Delivery throughout Russia - by transport company.

KLVS2536

AUTOMATIC VERTICAL GLASS ASSEMBLY LINE,

WITH FLAT PRESS.

GLASS ASSEMBLY INSIDE THE PRESS OR AT THE AUTOMATIC ASSEMBLY STATION.

Working height 2.5 m.

LINE DESCRIPTION

1. External or internal assembly program, comprehensive function

2. Automatic insulating glass production line with numerical control, LOW-E automatic identification

3. Siemens PLC control. Human-machine interface touch screen

4. Using imported vacuum generator and suction cup, led to the ideal glass sucking effect

5. Producing stepped (structural) insulating glass and triple glass according to different customer requests

6. Automatic variable frequency speed adjustment in the whole distance, which can save the waiting time of operation and improve the production efficiency.

MAIN CHARACTERISTICS

1) Input voltage – 380V, 50Hz

2) Total load: 30 W

3) Maximum glass size: 2500 x 3600 mm

4) Minimum glass size: 300 x 500 mm

5) Glass thickness: 3-12 mm

6) Glass feed speed: 8-45 m/min

7) Total line weight: 7000 kg

8) Dimensions of the assembled line: 26,000 x 1800 x 3600 mm