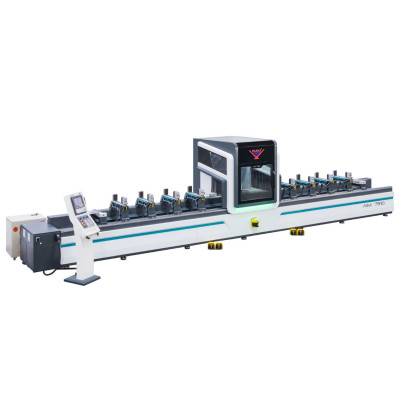

YILMAZ AIM 7510 CNC Machining Center 5-Axis

AIM 7510 is 5-axis servo-controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminium & PVC profiles, light alloys in general and thin walled steel profiles.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

Delivery throughout Russia - by transport company.

YILMAZ AIM 7510 5-AXIS CNC MACHINING CENTER FOR ALUMINUM PROFILES

YILMAZ AIM7510 5-AXIS CNC MACHINING CENTER FOR ALUMINUM, WOOD AND PLASTIC AIM 7510 is a 5-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles and low-carbon thin-walled steel profiles used in the market.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

Due to the feature of working with two stations, after finishing the workpiece processing at the first station, the machine automatically starts processing the workpiece at the 2nd station. At this time, the operator prepares the 1st station, thereby minimizing the waiting time during loading and unloading.

The machine has the property of automatic scanning and positioning of clamps, and working with two stations, the time loss during loading and unloading was minimized. When the machine is working with two stations, the time loss during loading and unloading is minimized.

CHARACTERISTICS

1) Automation system providing CNC movement in 5 axes.

2) Thanks to continuous operation with two stations, time losses are reduced to a minimum

3) Easy programming with the user-friendly CAMPROX CAM software

4) 2 separate tool magazines for 12 standard tools and 1 saw blade with a diameter of 350 mm

5) Housing made of steel profile and bridge structure with high dynamic characteristics.

6) Automatic clamp recognition and positioning feature

7) Thread cutting function (Optional)

8) Special soundproof cabin around the machining center

9) Using high-efficiency HSD spindle drive motor and quality products from renowned companies in their fields

10) CNC tool cooling unit

11) 8 automatic clamps used to grip the workpiece

12) 2 pneumatic stops used to zero the workpiece in the X direction.

13) Handwheel control unit for settings and manual movement

14) Three-zone laser scanning of the area to protect the operator

15) 10’’ color touch screen

16) Transfer programs from external sources using a USB flash drive

17) Programming language with “G” code according to ISO standard

18) Automatic lubrication system of the central system

19) LED lighting cabins

20) Multilingual support