Главная

There are 15 products.

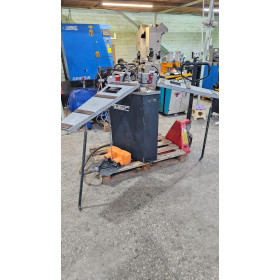

USED MURAT KB513, 2010 Single Head Welding Machine

USED MURAT KB513, 2010 YEAR OF PRODUCTION SINGLE-HEAD WELDING MACHINE, TURKEY

Single-head welding machine MURAT KB513, year of manufacture 2010. The machine is in perfect condition, like new, checked, configured. We can show it in operation. It practically did not work, was used for about six months on non-standard and alterations. Warehouse storage, the machine is not used in series, if necessary, we can connect and start it for testing. Location - Samara. We can send to the TC in the Russian Federation, non-cash sale without VAT, there will be a whole package of documents - a supply agreement, UPD, acceptance certificate, TTN for transportation.

Single-head welding machine MURAT KB513, year of manufacture 2010. The machine is in perfect condition, like new, checked, configured. We can show it in operation. It practically did not work, was used for about six months on non-standard and alterations. Warehouse storage, the machine is not used in series, if necessary, we can connect and start it for testing. Location - Samara. We can send to the TC in the Russian Federation, non-cash sale without VAT, there will be a whole package of documents - a supply agreement, UPD, acceptance certificate, TTN for transportation.

$4,000.00

copy of OZGENC OMRM136, 2014. Corner Crimping Machine

Pneumatic corner crimping press for joining corners of aluminum structures. Manufacturer OZGENC, Turkey. Model OMRM 136. Year of manufacture 2014. Condition is excellent. Included - pedals, side supports, knives. Warehouse storage. Can be connected and checked. Location - Samara. Shipment - pickup, delivery by a transport company is possible.

$5,300.00

FIMTEC SD25/S4 Double Head Cutting Saw (automatic)

Double-head automatic front saw FIMTEC SD25/S4. Designed for cutting two PVC or aluminum profiles at the same time. Saw blades 500 mm, in good condition. The cut length of workpieces at 90 and 45 degrees corresponds to the standard, no errors or backlashes are observed. Cutting at an angle is also within the standard, the angles after cutting match the specified parameters.

The machine is located in our warehouse in Samara, is not in serial operation, completely put in order both technically and in terms of appearance. Upon request, we are ready to send photos and videos, organize a video call with the warehouse, and also connect and show the equipment in operation with tests on the client's samples, if there is a desire to come in person and see everything.

We will help with loading onto your transport, we can also help with finding additional cargo. There is a forklift at the base, there will be no problems with sending.

The machine is located in our warehouse in Samara, is not in serial operation, completely put in order both technically and in terms of appearance. Upon request, we are ready to send photos and videos, organize a video call with the warehouse, and also connect and show the equipment in operation with tests on the client's samples, if there is a desire to come in person and see everything.

We will help with loading onto your transport, we can also help with finding additional cargo. There is a forklift at the base, there will be no problems with sending.

$12,800.00

Used MURAT KC258, 2017. Twin-Head Welding Machine

MURAT KC258, 2017

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

$0.00

Used MURAT KT-804 Sash Hardware Assembly Table

MURAT KT-804 HARDWARE ASSEMBLY STATION

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

$0.00

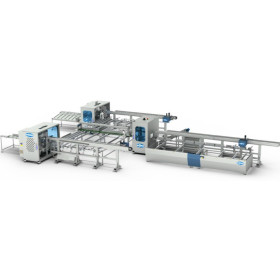

Used Haffner NR-242 Cutting&Milling Machining Center UPVC

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

$0.00

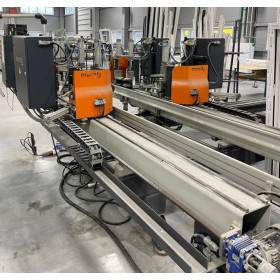

Used MURAT KD658/20 CNC 4-HEAD Welding Machine

KD658/20 4-Head Horizontal Welding Machine, 2019

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

$0.00

ZJS-CNC-600x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-600x4200

600mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

600mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$24,500.00

ZJS-CNC-550x4200 Double Head Cutting Saw CNC

ZJS-CNC-550x4200

550mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

550mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$22,500.00

ZJS-CNC-500x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-500x4200

500mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

500mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$21,500.00

ZJS-CNC-550x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-550x4200

550mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

550mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$23,500.00

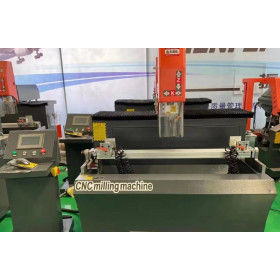

ZSD-CNC-800. CNC Copy Routing Machine

ZSD-CNC-800 CNC COPY ROUTING MACHINE. SINGLE SPINDLE

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

$10,800.00

ZSSD-CNC-800. CNC Copy Routing Machine

ZSSD-CNC-800 CNC COPY ROUTING MACHINE. DOUBLE SPINDLE

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

$12,350.00

ZSSD-CNC-3000. CNC Copy Routing Machine 3000 mm

ZSSD-CNC-3000 CNC COPY ROUTING MACHINE. DOUBLE SPINDLE

Feature

1. The machine adopts Taiwan DELTA CNC system, which can complete the hole and groove processing of

the cabinet door hinge in one clamping.

2. The dual spindles use high-speed spindles with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The processing G code is automatically converted through the programming software, which is simple to

operate, efficient and low in labor intensity.

5. The workbench automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the workbench, which is efficient and accurate

Feature

1. The machine adopts Taiwan DELTA CNC system, which can complete the hole and groove processing of

the cabinet door hinge in one clamping.

2. The dual spindles use high-speed spindles with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The processing G code is automatically converted through the programming software, which is simple to

operate, efficient and low in labor intensity.

5. The workbench automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the workbench, which is efficient and accurate

$31,000.00

ZFHD-CNC-3000 Aluminum CNC Machining Center With Automatic Tool Change

ZFHD-CNC-3000 Aluminum CNC Machining Center With Automatic Tool Change

Feature

1. Used for drilling/milling grooves/round holes/special-shaped holes/plane engraving and other processing

of aluminum alloy profiles.

2. The machine adopts Delta CNC system, which can complete continuous automatic milling of profiles of

different specifications and sizes.

3. The system comes with CAM, which makes editing hole types more intuitive and simple, and

automatically converts processing G codes, which is simple to operate, efficient and low in labor intensity.

4. CAD graphics can be imported and processed directly after editing.

Feature

1. Used for drilling/milling grooves/round holes/special-shaped holes/plane engraving and other processing

of aluminum alloy profiles.

2. The machine adopts Delta CNC system, which can complete continuous automatic milling of profiles of

different specifications and sizes.

3. The system comes with CAM, which makes editing hole types more intuitive and simple, and

automatically converts processing G codes, which is simple to operate, efficient and low in labor intensity.

4. CAD graphics can be imported and processed directly after editing.

$65,000.00