Главная

There are 59 products.

FENSTEK CCM120 Corner Crimping Machine 120 mm (pneumatic)

CCM120 CORNER CRIMPING MACHINE 120 mm

Aluminum Window Corner Crimping Machine

Features:

1. Aluminum corner crimper mainly used for crimping the 90 corner of aluminum window and door

2. Adopt new mechanical linkage device ,realized complete synchronous corner combining

3. Adjustable locating device suitable for various sections and sizes processing

4. Left and right punching heads adopt hard synchronous feeding device ,thus avoideduseless deformation and made the connection more firmly.

5. Easy machine setting due to the synchronous feeding device.

Aluminum Window Corner Crimping Machine

Features:

1. Aluminum corner crimper mainly used for crimping the 90 corner of aluminum window and door

2. Adopt new mechanical linkage device ,realized complete synchronous corner combining

3. Adjustable locating device suitable for various sections and sizes processing

4. Left and right punching heads adopt hard synchronous feeding device ,thus avoideduseless deformation and made the connection more firmly.

5. Easy machine setting due to the synchronous feeding device.

$14,500.00

FENSTEK ASD-6000 Industrial Screw Driver with Drilling Option

ASD-6000

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

$86,700.00

FENSTEK ADDSE Single Head Industrial Screw Driver

ADSSE Auto Screw Driver Machine for UPVC Window Features:

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

$6,500.00

FENSTEK SH-02 Single Head Welding Machine UPVC

FENSTEK SH-02 SINGLE-HEAD WELDING MACHINE

Features:

1. Single-head welding machine for UPVC windows is specially designed for welding at 90 degrees.

2. It can also weld at different angles between 0 and 180 degrees.

3. PLC-controlled machine operation.

4. Control of two separate clamping devices for easy operation.

5. It can weld white profile (2mm) and color profile (0.2mm). Mode switching is automatic, from the computer.

Features:

1. Single-head welding machine for UPVC windows is specially designed for welding at 90 degrees.

2. It can also weld at different angles between 0 and 180 degrees.

3. PLC-controlled machine operation.

4. Control of two separate clamping devices for easy operation.

5. It can weld white profile (2mm) and color profile (0.2mm). Mode switching is automatic, from the computer.

$10,600.00

FENSTEK HW2S260 Double Head Welding Machine UPVC

HW2S260 Double Head Welding Machine for Laminated Profile Welding

FEATURES

1. The double head welding machine for PVC window is specially designed for welding PVC laminated window profile with 0.2mm welding result.

2. High efficiency of welding and surface cleaning in one machine.

3. Manual adjustment can also realize 2mm welding.

4. Unique maximum welding height of 260mm.

5. All movement systems adopt high-precision square bearings.

6. Pneumatic braking device.

7. Solid base and machine structure ensure long service life with high precision.

8. Profile clamp ordered separately can meet the processing requirements of various profiles

FEATURES

1. The double head welding machine for PVC window is specially designed for welding PVC laminated window profile with 0.2mm welding result.

2. High efficiency of welding and surface cleaning in one machine.

3. Manual adjustment can also realize 2mm welding.

4. Unique maximum welding height of 260mm.

5. All movement systems adopt high-precision square bearings.

6. Pneumatic braking device.

7. Solid base and machine structure ensure long service life with high precision.

8. Profile clamp ordered separately can meet the processing requirements of various profiles

$31,200.00

FENSTEK HTW2-120 Double Head Welding Machine UPVC

FENSTEK HTW2-120

DOUBLE-HEAD WELDING MACHINE

Features

1. The double-head welding machine for UPVC windows is the most popular type of equipment with 2mm welding.

2. The guide with insert is used.

3. The last head of the machine can weld at different angles from 30 to 180 degrees.

4. The solid base and structure of the machine ensure a long service life with high dimensional accuracy.

5. The profile fastener ordered separately can meet the processing requirements of profiles of different heights.

6. The special profile fastener is easy to replace, which ensures high strength of the angle and good cleaning afterwards.

7. Each head of the machine can work separately or in combination

DOUBLE-HEAD WELDING MACHINE

Features

1. The double-head welding machine for UPVC windows is the most popular type of equipment with 2mm welding.

2. The guide with insert is used.

3. The last head of the machine can weld at different angles from 30 to 180 degrees.

4. The solid base and structure of the machine ensure a long service life with high dimensional accuracy.

5. The profile fastener ordered separately can meet the processing requirements of profiles of different heights.

6. The special profile fastener is easy to replace, which ensures high strength of the angle and good cleaning afterwards.

7. Each head of the machine can work separately or in combination

$16,200.00

FENSTEK ADS600*4500 Double Head CNC Arbitrary Angle Saw

FENSTEK ADS600*4500 CNC B2B TWO-HEAD FRONT SAW WITH SERVO DRIVE

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

$63,600.00

FENSTEK ADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$33,000.00

FENSTEK IADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$43,500.00

DJJ07 Automatic Butyl Extruder

Butyl coating machine-DJJ07

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency.

DJJ07 Butyl Coating Machine

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency. Adjust the distance between two glue nozzle automatically. Adjust the glue output automatically according to running speed. It has the advantage of long service life and high degree of automation, etc

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency.

DJJ07 Butyl Coating Machine

This butyl coating machine is special equipment at domestic and abroad with the top technology gluing on both sides of the aluminum spacer, with uniform coating, adhesive capacity, fast speed, high production efficiency. Adjust the distance between two glue nozzle automatically. Adjust the glue output automatically according to running speed. It has the advantage of long service life and high degree of automation, etc

$0.00

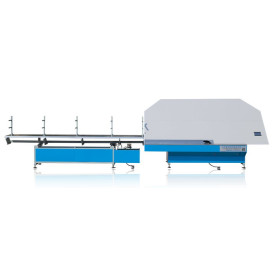

LBP2500C IG LINE 2,5 m

Insulating glass machine C Series (Machinery of this series adopts IG Outer-panel Assembly. Effect high-speed IG production efficiency

Insulating Glass Production Line C Series

Outer-panel Assembly Insulating Glass Production Line

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, out-panel (and inner-panel) assembly, large stroke press machine and output section (title table), adopts advanced IG manufacture technology and craft. This production line can choose out-panel assembly or inner-panel assembly to process same edge single and double insulating glass un

Insulating Glass Production Line C Series

Outer-panel Assembly Insulating Glass Production Line

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, out-panel (and inner-panel) assembly, large stroke press machine and output section (title table), adopts advanced IG manufacture technology and craft. This production line can choose out-panel assembly or inner-panel assembly to process same edge single and double insulating glass un

$0.00

LBP2500S IG Line 2,5 m

Insulating glass machine S Series (Machinery of this series is with argon gas filling on-line and double station in aluminum spacer location section)

The production line adopts advanced manufacturing craft and technology of insulating glass making. It is mainly composed of glass loading, cleaning and drying, transmission, dual-station light inspection and aluminum spacer location, automatic assembly, large stroke pressing (internal assembly, argon gas filling inline) and transmission after pressing into double glazing glass

The production line adopts advanced manufacturing craft and technology of insulating glass making. It is mainly composed of glass loading, cleaning and drying, transmission, dual-station light inspection and aluminum spacer location, automatic assembly, large stroke pressing (internal assembly, argon gas filling inline) and transmission after pressing into double glazing glass

$0.00

ZFGJ-02B Automatic Desiccant Filling Machine

Automatic molecular sieve filling machine

Adopt PLC control system and touch human-machine interface

ZFGJ-02B Automatic Desiccant Filling Machine

Main features

1. Adopt PLC control system and touch human-machine interface.

2. Can fill bendable and non-bendable aluminum frame.

3. Adjust filling height according to the various sizes of the aluminum frame.

4. High filling speed by drilling holes in the back.

5. Seal the filling holes automatically.

6. Monitoring the quantity of desiccant and replenish material automatically.

7. The model can be with double-station operating, save manpower, high efficiency

Adopt PLC control system and touch human-machine interface

ZFGJ-02B Automatic Desiccant Filling Machine

Main features

1. Adopt PLC control system and touch human-machine interface.

2. Can fill bendable and non-bendable aluminum frame.

3. Adjust filling height according to the various sizes of the aluminum frame.

4. High filling speed by drilling holes in the back.

5. Seal the filling holes automatically.

6. Monitoring the quantity of desiccant and replenish material automatically.

7. The model can be with double-station operating, save manpower, high efficiency

$0.00

ZLZW-02 Aluminium Spacer Bending Machine

Automatic spacer bending machine

Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

ZLZW02 Automatic aluminum spacer bending machine

Main features

1. Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

2. Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc).

3. Aluminum frame have smooth arc, which is beautiful after butyl coating.

4. Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency.

5. Can feed four different size of aluminum spacer with four store tanks.

6. Automactic avoid spacer joint when bending and cutting spacer.

7. Can do shaped aluminum frame.

Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

ZLZW02 Automatic aluminum spacer bending machine

Main features

1. Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

2. Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc).

3. Aluminum frame have smooth arc, which is beautiful after butyl coating.

4. Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency.

5. Can feed four different size of aluminum spacer with four store tanks.

6. Automactic avoid spacer joint when bending and cutting spacer.

7. Can do shaped aluminum frame.

$0.00

SDQ-III Two Component Sealant Extruder

Two component sealant extruder (SDQ-III)

It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism

SDQ-III Two-component Sealant Extruders

Main features

1. It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism.

2. The needle one-way valve could ensure that the mixture will not reflow to avoid the pipe solidification.

3. Fully closed curing agent glue system, avoid curing agent and air contact and curing.

4. Sensitive high-pressure protective value makes the operation in safe condition.

5. Gas pressure driven has the performance of stable pressure, uniform output.

6. Adopt international popular static reciprocating mixer, mixing more uniform.

7. The main raw materials: silicone sealant, polysulfide sealant, polyurethane adhesive

It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism

SDQ-III Two-component Sealant Extruders

Main features

1. It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism.

2. The needle one-way valve could ensure that the mixture will not reflow to avoid the pipe solidification.

3. Fully closed curing agent glue system, avoid curing agent and air contact and curing.

4. Sensitive high-pressure protective value makes the operation in safe condition.

5. Gas pressure driven has the performance of stable pressure, uniform output.

6. Adopt international popular static reciprocating mixer, mixing more uniform.

7. The main raw materials: silicone sealant, polysulfide sealant, polyurethane adhesive

$0.00

DJJ06 Automatic Butyl Extruder

Butyl coating machine-DJJ06

Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate

Main features

1. Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate, etc.

2. Adopts PLC control system with touch screen interface.

3. Adjust the distance between two glue nozzle by automatic hydraulic cylinder, fast and convenient.

4. Can glue round spacer.

5. Five gear frequency control.

6. The glue tanker diameter 200mm, length 450mm, is suitable for all kinds of butyl.

7. 24 hour timer switch, saving warm-up time, improve work efficiency.

Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate

Main features

1. Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate, etc.

2. Adopts PLC control system with touch screen interface.

3. Adjust the distance between two glue nozzle by automatic hydraulic cylinder, fast and convenient.

4. Can glue round spacer.

5. Five gear frequency control.

6. The glue tanker diameter 200mm, length 450mm, is suitable for all kinds of butyl.

7. 24 hour timer switch, saving warm-up time, improve work efficiency.

$0.00

ZDJ-2025V IG Sealing Robot

Automatic Sealing Robot

Gluing part adopts special relocation mechanism, ensure the gluing nozzle will touch IG unit closely, but will not break it. And it can adapt to a certain range of displacement error of IG unit.

Available Models: ZDJ-18V / ZDJ-20V / ZDJ-25V

Gluing part adopts special relocation mechanism, ensure the gluing nozzle will touch IG unit closely, but will not break it. And it can adapt to a certain range of displacement error of IG unit.

Available Models: ZDJ-18V / ZDJ-20V / ZDJ-25V

$0.00

RST Rotating Table

Rotating Sealing Table

Main Feature

1. Adopt vacuum ejector structure adsorbing the glass well.

2. Turning round 90 degree every time , orientating exactly, operating and extruding glue conveniently.

3. Convenient to extrude glue and convey for big glass

Main Feature

1. Adopt vacuum ejector structure adsorbing the glass well.

2. Turning round 90 degree every time , orientating exactly, operating and extruding glue conveniently.

3. Convenient to extrude glue and convey for big glass

$0.00

LBP2500Q IG LINE 2,5 m

Automatic insulating glass machine Q Series (Machinery of this series is with argon gas filling on-line)

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, inner-panel assembly, argon gas filling & press section and output section (title table), adopts advanced IG manufacture technology and craft . This production line can fill argon gas during pressing into insulating glass.

Model: LBP1800Q / LBP2000Q / LBP2500Q / LBP2850Q / LBP3000Q / LBP3300Q

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, inner-panel assembly, argon gas filling & press section and output section (title table), adopts advanced IG manufacture technology and craft . This production line can fill argon gas during pressing into insulating glass.

Model: LBP1800Q / LBP2000Q / LBP2500Q / LBP2850Q / LBP3000Q / LBP3300Q

$0.00