Главная

There are 31 products.

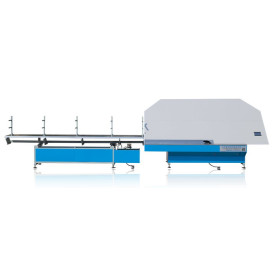

ZLZW-02 Aluminium Spacer Bending Machine

Automatic spacer bending machine

Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

ZLZW02 Automatic aluminum spacer bending machine

Main features

1. Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

2. Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc).

3. Aluminum frame have smooth arc, which is beautiful after butyl coating.

4. Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency.

5. Can feed four different size of aluminum spacer with four store tanks.

6. Automactic avoid spacer joint when bending and cutting spacer.

7. Can do shaped aluminum frame.

Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

ZLZW02 Automatic aluminum spacer bending machine

Main features

1. Adopt PLC control system and touch human-machine interface. Multi-screen clear and technical parameter simply input.

2. Feeding material and bending aluminum spacer by servo motor guarantees the precision of the bending form (angle and arc).

3. Aluminum frame have smooth arc, which is beautiful after butyl coating.

4. Bending aluminum frame and theoretical size error is less than 1mm, high speed, high efficiency.

5. Can feed four different size of aluminum spacer with four store tanks.

6. Automactic avoid spacer joint when bending and cutting spacer.

7. Can do shaped aluminum frame.

$0.00

SDQ-III Two Component Sealant Extruder

Two component sealant extruder (SDQ-III)

It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism

SDQ-III Two-component Sealant Extruders

Main features

1. It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism.

2. The needle one-way valve could ensure that the mixture will not reflow to avoid the pipe solidification.

3. Fully closed curing agent glue system, avoid curing agent and air contact and curing.

4. Sensitive high-pressure protective value makes the operation in safe condition.

5. Gas pressure driven has the performance of stable pressure, uniform output.

6. Adopt international popular static reciprocating mixer, mixing more uniform.

7. The main raw materials: silicone sealant, polysulfide sealant, polyurethane adhesive

It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism

SDQ-III Two-component Sealant Extruders

Main features

1. It is easy to adjust the ratio through adjustable pressure synchronous linkage mechanism.

2. The needle one-way valve could ensure that the mixture will not reflow to avoid the pipe solidification.

3. Fully closed curing agent glue system, avoid curing agent and air contact and curing.

4. Sensitive high-pressure protective value makes the operation in safe condition.

5. Gas pressure driven has the performance of stable pressure, uniform output.

6. Adopt international popular static reciprocating mixer, mixing more uniform.

7. The main raw materials: silicone sealant, polysulfide sealant, polyurethane adhesive

$0.00

DJJ06 Automatic Butyl Extruder

Butyl coating machine-DJJ06

Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate

Main features

1. Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate, etc.

2. Adopts PLC control system with touch screen interface.

3. Adjust the distance between two glue nozzle by automatic hydraulic cylinder, fast and convenient.

4. Can glue round spacer.

5. Five gear frequency control.

6. The glue tanker diameter 200mm, length 450mm, is suitable for all kinds of butyl.

7. 24 hour timer switch, saving warm-up time, improve work efficiency.

Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate

Main features

1. Booster pump imported from Germany, has the advantages of sensitive pressure regulator, small pressure fluctuation, stable and high quality glue, and aluminum adjustment convenient and accurate, etc.

2. Adopts PLC control system with touch screen interface.

3. Adjust the distance between two glue nozzle by automatic hydraulic cylinder, fast and convenient.

4. Can glue round spacer.

5. Five gear frequency control.

6. The glue tanker diameter 200mm, length 450mm, is suitable for all kinds of butyl.

7. 24 hour timer switch, saving warm-up time, improve work efficiency.

$0.00

ZDJ-2025V IG Sealing Robot

Automatic Sealing Robot

Gluing part adopts special relocation mechanism, ensure the gluing nozzle will touch IG unit closely, but will not break it. And it can adapt to a certain range of displacement error of IG unit.

Available Models: ZDJ-18V / ZDJ-20V / ZDJ-25V

Gluing part adopts special relocation mechanism, ensure the gluing nozzle will touch IG unit closely, but will not break it. And it can adapt to a certain range of displacement error of IG unit.

Available Models: ZDJ-18V / ZDJ-20V / ZDJ-25V

$0.00

RST Rotating Table

Rotating Sealing Table

Main Feature

1. Adopt vacuum ejector structure adsorbing the glass well.

2. Turning round 90 degree every time , orientating exactly, operating and extruding glue conveniently.

3. Convenient to extrude glue and convey for big glass

Main Feature

1. Adopt vacuum ejector structure adsorbing the glass well.

2. Turning round 90 degree every time , orientating exactly, operating and extruding glue conveniently.

3. Convenient to extrude glue and convey for big glass

$0.00

USED YILMAZ DC421MS_2011 Double Head Saw Semi-Automatic

USED YILMAZ DC421MS_2012 TWO-HEAD FRONT SAW SEMIAUTOMATIC

Two-head front saw, semiautomatic. YILMAZ DC420MS, 2011. The equipment is in excellent condition. The saw has been completely repaired. New screens have been installed on the protective covers, the specified angles and cutting length are normal, the saw blades are in order, the bearings and belts have been replaced, an extension for maximum cuts is available, a new cooling system has been installed, the electronic size indicator works without errors. Absolutely everything has been done on the machine, no additional actions are required for normal operation.

The equipment can be viewed in operation, tested in our warehouse. Sale is possible under a contract, non-cash payment without VAT. We will provide the entire set of documents - supply agreement, UPD, acceptance certificate, TTN. The saw is ready for shipment, we will provide loading onto your transport.

Location: Samara, warehouse storage.

Two-head front saw, semiautomatic. YILMAZ DC420MS, 2011. The equipment is in excellent condition. The saw has been completely repaired. New screens have been installed on the protective covers, the specified angles and cutting length are normal, the saw blades are in order, the bearings and belts have been replaced, an extension for maximum cuts is available, a new cooling system has been installed, the electronic size indicator works without errors. Absolutely everything has been done on the machine, no additional actions are required for normal operation.

The equipment can be viewed in operation, tested in our warehouse. Sale is possible under a contract, non-cash payment without VAT. We will provide the entire set of documents - supply agreement, UPD, acceptance certificate, TTN. The saw is ready for shipment, we will provide loading onto your transport.

Location: Samara, warehouse storage.

$11,000.00

Used MURAT KC258, 2017. Twin-Head Welding Machine

MURAT KC258, 2017

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

Two-head welding machine with top feed of heating elements;

- The machine welds the outer surface of the profile with a thickness of 0.2 to 0.4 mm;

- This technology allows you to get a thin front seam on a laminated PVC profile, the appearance of which is much more attractive than standard welding;

- The right welding head allows you to weld profiles only at an angle of 90 degrees, the left one - with a variable angle;

- The right welding head moves manually along the guides;

- The working cycle is automatic;

- The electronic system of the machine allows you to set welding modes (adjust the heating and compression time of the workpieces, the compression force of the workpieces) and constantly monitor them;

- The electronic display on the control panel provides information on all working cycles and emergency failures

$0.00

Used MURAT KT-804 Sash Hardware Assembly Table

MURAT KT-804 HARDWARE ASSEMBLY STATION

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

$0.00

Used Haffner NR-242 Cutting&Milling Machining Center UPVC

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

$0.00

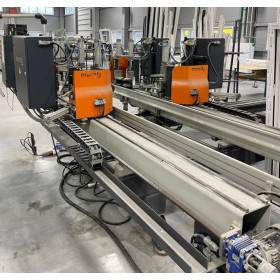

Used MURAT KD658/20 CNC 4-HEAD Welding Machine

KD658/20 4-Head Horizontal Welding Machine, 2019

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

Includes CK187 Cooling Station.

Manufacturer: Murat-Haffner, Turkey

We can arrange and provide commissioning for an additional fee.

We provide individual cost and commissioning estimates. We provide dismantling, delivery, installation, commissioning, and training. We provide a full range of services through our in-house service department.

Price includes VAT; quote available upon request.

Price below market for sale in December 2025.

We operate under a formal supply contract.

Videos and photos can also be sent via WhatsApp.

The equipment is almost new and in excellent condition.

$0.00

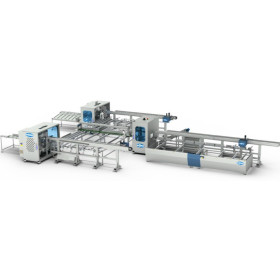

LBP2500Q IG LINE 2,5 m

Automatic insulating glass machine Q Series (Machinery of this series is with argon gas filling on-line)

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, inner-panel assembly, argon gas filling & press section and output section (title table), adopts advanced IG manufacture technology and craft . This production line can fill argon gas during pressing into insulating glass.

Model: LBP1800Q / LBP2000Q / LBP2500Q / LBP2850Q / LBP3000Q / LBP3300Q

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, inner-panel assembly, argon gas filling & press section and output section (title table), adopts advanced IG manufacture technology and craft . This production line can fill argon gas during pressing into insulating glass.

Model: LBP1800Q / LBP2000Q / LBP2500Q / LBP2850Q / LBP3000Q / LBP3300Q

$0.00