USED MACHINES FOR PVC & ALUMINUM (FROM STOCK)

There are 2 products.

Used MURAT KT-804 Sash Hardware Assembly Table

MURAT KT-804 HARDWARE ASSEMBLY STATION

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

The MURAT KT-804 assembly table enables high-quality assembly of window and door sash opening systems on-the-fly. The KT-804 assembly table allows for the installation of both simple (tilt and turn) and complex (tilt-and-turn) sash opening systems.

Speed up work by performing multiple processes on a single table.

Triple drilling of handle holes.

And milling of bolt holes with easy tool positioning.

Cutting unit for simple and tilt-and-turn sash opening mechanisms and hinges without measuring.

Height-adjustable automatic screwdriver for bolts and hinges.

Drilling of hinge holes on-site without measuring.

Ergonomic work thanks to a 15° tilting work table.

Standard equipment shelves for equipment and tools.

$0.00

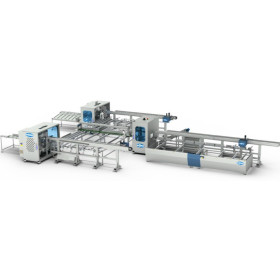

Used Haffner NR-242 Cutting&Milling Machining Center UPVC

MURAT-HAFFNER. SAWING AND PROCESSING CENTER.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

Model NR-242

The sawing and processing center is equipped with an automatic cutting module and two processing modules (frame and sash). The capacity is 200-240 pieces per shift.

This center's concept involves first cutting long profiles according to the shift assignment, then transferring frames and sashes cut at 45 degrees, as well as mullions cut at 90 degrees, to the processing module. Before this, the operator inserts reinforcement into the PVC, as further processing is performed on metal. The center is equipped with triple drilling options, a drill for mullion holes in metal, and an automatic dual-head screwdriver for screwing PVC and reinforcement.

$0.00