Главная

There are 52 products.

SINON LDJZ1-120 Pneumatic Screw Driver

SINON LDJZ1-120 Pneumatic Screw Driver

LDJZ1-120 is used for fastening the Reinforcement of the PVC window and door /

PLC control system, France Schneider system

FEATURES:

● This machine used for fastening the Reinforcement of the PVC window and door.

● Adopt PLC programming controller, it’s reliable and stably.

● The machine head is adjustable from front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

● Auto feeding and distributing screws by special feeding device, with without screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory.

● With standard two sets of 2M supporting bracket.

LDJZ1-120 is used for fastening the Reinforcement of the PVC window and door /

PLC control system, France Schneider system

FEATURES:

● This machine used for fastening the Reinforcement of the PVC window and door.

● Adopt PLC programming controller, it’s reliable and stably.

● The machine head is adjustable from front to back according to profile width. Front and back distance adjustment adopt infrared distance measurement, the location easy and accuracy.

● Auto feeding and distributing screws by special feeding device, with without screw inspection function, with high working efficiency, it’s the ideal machine for batch window and door factory.

● With standard two sets of 2M supporting bracket.

$5,200.00

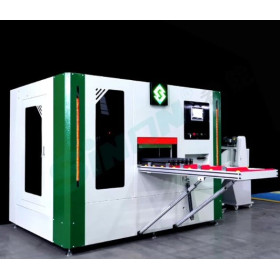

LJKJ-CNC-600 CNC Notching Saw Aluminium

For the first time in Russia. New model of CNC Facade Notching Saw.

Manufactured by SINON, China.

High-quality equipment from an authorized dealer in Russia.

We deliver to order.

Model LJKJ-CNC-600. CNC machine, single 600 mm diameter saw blade, cooling, 180-degree blade rotation. Extensive library of possible notching options. Any non-standard façade profile notches. High blade movement and rotation speed. The portal moves in three axes, and the blade angle is adjusted automatically. The work table can also be rotated to the desired angle, with the set angle displayed on the electronic display.

Delivery time is 3-4 months. We work with VAT under contract. Import into Russia is completely legal, official delivery, no gray areas. Reliable, efficient, and safe. We have been operating in the Russian market for over 20 years.

The price of the equipment includes delivery to the client, commissioning work, and training of personnel to operate the equipment.

Manufactured by SINON, China.

High-quality equipment from an authorized dealer in Russia.

We deliver to order.

Model LJKJ-CNC-600. CNC machine, single 600 mm diameter saw blade, cooling, 180-degree blade rotation. Extensive library of possible notching options. Any non-standard façade profile notches. High blade movement and rotation speed. The portal moves in three axes, and the blade angle is adjusted automatically. The work table can also be rotated to the desired angle, with the set angle displayed on the electronic display.

Delivery time is 3-4 months. We work with VAT under contract. Import into Russia is completely legal, official delivery, no gray areas. Reliable, efficient, and safe. We have been operating in the Russian market for over 20 years.

The price of the equipment includes delivery to the client, commissioning work, and training of personnel to operate the equipment.

$50,500.00

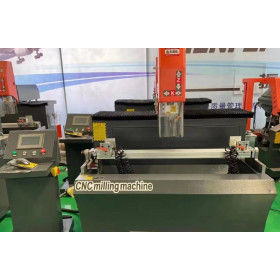

SZA-400 ULTRA 5-Axis CNC End Milling Machine

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows.

Model: SZA400

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

$31,800.00

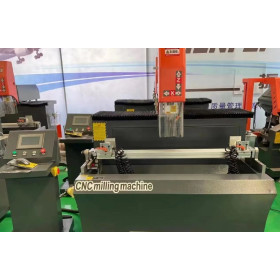

SZA-400V ULTRA 5-Axis CNC End Milling Machine

SINON - CHINESE EQUIPMENT FROM A LARGE FACTORY.

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400V. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows. Variable Angle of Milling

Model: SZA400V

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

EXCLUSIVELY IN RUSSIA. WE GUARANTEE THE BEST QUALITY.

IN STOCK SALE, IN STOCK from an authorized dealer. LEASING AVAILABLE

SINON SZA-400V. CNC MILLING MACHINE FOR PROCESSING END CUTTING OF ALUMINUM PROFILES.

Specifications

Used for milling end cutting of aluminum profiles for doors and windows. Variable Angle of Milling

Model: SZA400V

Power voltage: 380 V, 50 Hz

Total equipment power: 11 kW

Spindle speed: 2850 rpm

Workbench width: 595 mm

Diameter: φ30 mm

Cutter diameter: φ350 mm

Maximum milling depth: 120 mm

Maximum milling height: 200 mm

Dimensions: 2880 x 1880 x 2160 mm

Weight: 1950 kg

$36,000.00

ZJS-CNC-600x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-600x4200

600mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

600mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$24,500.00

ZJS-CNC-550x4200 Double Head Cutting Saw CNC

ZJS-CNC-550x4200

550mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

550mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$22,500.00

ZJS-CNC-500x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-500x4200

500mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

500mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$21,500.00

ZJS-CNC-550x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-550x4200

550mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

550mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$23,500.00

ZSD-CNC-800. CNC Copy Routing Machine

ZSD-CNC-800 CNC COPY ROUTING MACHINE. SINGLE SPINDLE

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

$10,800.00

ZSSD-CNC-800. CNC Copy Routing Machine

ZSSD-CNC-800 CNC COPY ROUTING MACHINE. DOUBLE SPINDLE

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

$12,350.00

ZSSD-CNC-3000. CNC Copy Routing Machine 3000 mm

ZSSD-CNC-3000 CNC COPY ROUTING MACHINE. DOUBLE SPINDLE

Feature

1. The machine adopts Taiwan DELTA CNC system, which can complete the hole and groove processing of

the cabinet door hinge in one clamping.

2. The dual spindles use high-speed spindles with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The processing G code is automatically converted through the programming software, which is simple to

operate, efficient and low in labor intensity.

5. The workbench automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the workbench, which is efficient and accurate

Feature

1. The machine adopts Taiwan DELTA CNC system, which can complete the hole and groove processing of

the cabinet door hinge in one clamping.

2. The dual spindles use high-speed spindles with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The processing G code is automatically converted through the programming software, which is simple to

operate, efficient and low in labor intensity.

5. The workbench automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the workbench, which is efficient and accurate

$31,000.00

ZFHD-CNC-3000 Aluminum CNC Machining Center With Automatic Tool Change

ZFHD-CNC-3000 Aluminum CNC Machining Center With Automatic Tool Change

Feature

1. Used for drilling/milling grooves/round holes/special-shaped holes/plane engraving and other processing

of aluminum alloy profiles.

2. The machine adopts Delta CNC system, which can complete continuous automatic milling of profiles of

different specifications and sizes.

3. The system comes with CAM, which makes editing hole types more intuitive and simple, and

automatically converts processing G codes, which is simple to operate, efficient and low in labor intensity.

4. CAD graphics can be imported and processed directly after editing.

Feature

1. Used for drilling/milling grooves/round holes/special-shaped holes/plane engraving and other processing

of aluminum alloy profiles.

2. The machine adopts Delta CNC system, which can complete continuous automatic milling of profiles of

different specifications and sizes.

3. The system comes with CAM, which makes editing hole types more intuitive and simple, and

automatically converts processing G codes, which is simple to operate, efficient and low in labor intensity.

4. CAD graphics can be imported and processed directly after editing.

$65,000.00