Главная

There are 55 products.

FENSTEK ASD-6000 Industrial Screw Driver with Drilling Option

ASD-6000

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

$86,700.00

FENSTEK ADDSE Single Head Industrial Screw Driver

ADSSE Auto Screw Driver Machine for UPVC Window Features:

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

$6,500.00

FENSTEK SH-02 Single Head Welding Machine UPVC

FENSTEK SH-02 SINGLE-HEAD WELDING MACHINE

Features:

1. Single-head welding machine for UPVC windows is specially designed for welding at 90 degrees.

2. It can also weld at different angles between 0 and 180 degrees.

3. PLC-controlled machine operation.

4. Control of two separate clamping devices for easy operation.

5. It can weld white profile (2mm) and color profile (0.2mm). Mode switching is automatic, from the computer.

Features:

1. Single-head welding machine for UPVC windows is specially designed for welding at 90 degrees.

2. It can also weld at different angles between 0 and 180 degrees.

3. PLC-controlled machine operation.

4. Control of two separate clamping devices for easy operation.

5. It can weld white profile (2mm) and color profile (0.2mm). Mode switching is automatic, from the computer.

$10,600.00

FENSTEK HW2S260 Double Head Welding Machine UPVC

HW2S260 Double Head Welding Machine for Laminated Profile Welding

FEATURES

1. The double head welding machine for PVC window is specially designed for welding PVC laminated window profile with 0.2mm welding result.

2. High efficiency of welding and surface cleaning in one machine.

3. Manual adjustment can also realize 2mm welding.

4. Unique maximum welding height of 260mm.

5. All movement systems adopt high-precision square bearings.

6. Pneumatic braking device.

7. Solid base and machine structure ensure long service life with high precision.

8. Profile clamp ordered separately can meet the processing requirements of various profiles

FEATURES

1. The double head welding machine for PVC window is specially designed for welding PVC laminated window profile with 0.2mm welding result.

2. High efficiency of welding and surface cleaning in one machine.

3. Manual adjustment can also realize 2mm welding.

4. Unique maximum welding height of 260mm.

5. All movement systems adopt high-precision square bearings.

6. Pneumatic braking device.

7. Solid base and machine structure ensure long service life with high precision.

8. Profile clamp ordered separately can meet the processing requirements of various profiles

$31,200.00

FENSTEK HTW2-120 Double Head Welding Machine UPVC

FENSTEK HTW2-120

DOUBLE-HEAD WELDING MACHINE

Features

1. The double-head welding machine for UPVC windows is the most popular type of equipment with 2mm welding.

2. The guide with insert is used.

3. The last head of the machine can weld at different angles from 30 to 180 degrees.

4. The solid base and structure of the machine ensure a long service life with high dimensional accuracy.

5. The profile fastener ordered separately can meet the processing requirements of profiles of different heights.

6. The special profile fastener is easy to replace, which ensures high strength of the angle and good cleaning afterwards.

7. Each head of the machine can work separately or in combination

DOUBLE-HEAD WELDING MACHINE

Features

1. The double-head welding machine for UPVC windows is the most popular type of equipment with 2mm welding.

2. The guide with insert is used.

3. The last head of the machine can weld at different angles from 30 to 180 degrees.

4. The solid base and structure of the machine ensure a long service life with high dimensional accuracy.

5. The profile fastener ordered separately can meet the processing requirements of profiles of different heights.

6. The special profile fastener is easy to replace, which ensures high strength of the angle and good cleaning afterwards.

7. Each head of the machine can work separately or in combination

$16,200.00

FENSTEK ADS600*4500 Double Head CNC Arbitrary Angle Saw

FENSTEK ADS600*4500 CNC B2B TWO-HEAD FRONT SAW WITH SERVO DRIVE

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

SUPPLY ON ORDER!!!

TWO-HEAD FRONT SAW FOR ALUMINUM WITH CNC.

Industrial PLC, label printer installed. 600 mm blades, cooling. Maximum cutting length 4500 mm.

Functions:

1. Double-head three-axis front saw with CNC for cutting at any angle.

2. The machine is similar to European models.

3. The machine has a modern control system.

4. The saw blade with direct drive has a lever type of cutting.

5. The saw blades are fed using a hydraulic damping cylinder, ensuring smooth cutting.

6. The imported control system ensures cutting quality.

7. The cutting task can be uploaded to the machine via the network. The cutting length can also be input directly.

8. The servo motor drives the speed reducer, adjusting the cutting angle: 45.0 ° - 135 °.

$63,600.00

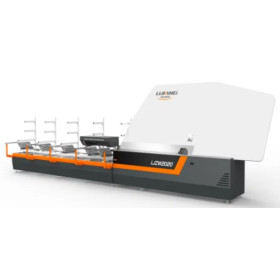

FENSTEK ADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$33,000.00

FENSTEK IADS550*4200 Double Head Cutting Machine (automatic)

ADS550*4200 Aluminum Window CNC Double Head Cutting Saw

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

Features:

1.Automatic cutting Aluminum&UPVC profile.

2.Adopting the most advanced numerical controlling system driving machine moving and position automatically. High precision and easy operation.

3.Unique swing arm feeding system assure high quality cutting result.

4.Auto -45°~ 90°cutting change

5.Auto safety cover for safety operation.

6.Imported linear guiding pair ensured steady processing accuracy.

7.Saw blade rotates smoothly due to high accuracy spindle.

8.Hydraulic feeding systems ensure precise and stable feeding.

9.Carbide saw blade is of accurate processing and high efficiency.

10.Two heads can work together or single, when together work, one time can cut off the required length and angle cut can be cut at one time

$43,500.00

LJBZ2540 INSULATING GLASS UNIT ASSEMBLY LINE

LJBZ2540 Automatic Vertical Insulating Glass Assembly Line

Features

• Siemens PLC control system (Germany), touchscreen interface

• Automatic detection of coated and low-e glass

• 3 pairs of soft brushes for online and offline washing of low-e glass

• The washing machine uses stainless steel and is waterproof

• Air heating system

• Automatic fan start and stop

• Noise reduction system

• Online washing speed display

• Intelligent intermittent operation mode, energy saving

• Adjustable pressure plate to maintain a flat pressure surface

• Automatic gas filling: gas concentration can be set and the filling process is displayed online at high gas concentrations

• Connection via aviation plug

• Designed for the production of single-chamber, double-chamber, and structural (stepped) glass double-glazed windows

Features

• Siemens PLC control system (Germany), touchscreen interface

• Automatic detection of coated and low-e glass

• 3 pairs of soft brushes for online and offline washing of low-e glass

• The washing machine uses stainless steel and is waterproof

• Air heating system

• Automatic fan start and stop

• Noise reduction system

• Online washing speed display

• Intelligent intermittent operation mode, energy saving

• Adjustable pressure plate to maintain a flat pressure surface

• Automatic gas filling: gas concentration can be set and the filling process is displayed online at high gas concentrations

• Connection via aviation plug

• Designed for the production of single-chamber, double-chamber, and structural (stepped) glass double-glazed windows

$0.00

LJTJ2540 CNC Sealing Robot

Vertical Insulating Glass Sealing Robot

Model LJTJ2540

Main Features:

• Japanese Yaskawa servo control system, 8 axes, 7 sets of servo drives, fully automatic and highly efficient sealing machine

• 4 sections, glass storage option

• Toothed belt drive, smooth transmission and precise positioning

• Automatic glass corner sealing with a scraper and roller

• Automatic glass size and adhesive depth measurement

• All automatic functions are manually controlled

• Capable of coating double/triple glazing

• One booster pump set controls two sealant groups (optional)

• Suitable for silicone, polysulfide, and silicone structural sealants

• Can be connected to an insulating glass processing line

Model LJTJ2540

Main Features:

• Japanese Yaskawa servo control system, 8 axes, 7 sets of servo drives, fully automatic and highly efficient sealing machine

• 4 sections, glass storage option

• Toothed belt drive, smooth transmission and precise positioning

• Automatic glass corner sealing with a scraper and roller

• Automatic glass size and adhesive depth measurement

• All automatic functions are manually controlled

• Capable of coating double/triple glazing

• One booster pump set controls two sealant groups (optional)

• Suitable for silicone, polysulfide, and silicone structural sealants

• Can be connected to an insulating glass processing line

$0.00

LJTB01 BUTYL EXTRUDER

LJTB01 Butyl Extruder

Key Features:

Butyl extrusion speed can reach 47 m/min.

• Butyl savings compared to conventional equipment: adhesive consumption reaches 7 g/m.

• Automatic exhaust function ensures continuous butyl application.

• PLC control system, touchscreen.

• Glue-free synchronous belt ensures belt cleanliness.

• Main components are made from materials from renowned German manufacturers, ensuring stable operation.

• Automatic gluing head width adjustment ensures uniform butyl application on both sides thanks to a built-in quick-release control valve.

• Use of a movable vertical butyl feed mechanism and horizontal extrusion is convenient and practical.

• On/off time can be adjusted to suit needs

Key Features:

Butyl extrusion speed can reach 47 m/min.

• Butyl savings compared to conventional equipment: adhesive consumption reaches 7 g/m.

• Automatic exhaust function ensures continuous butyl application.

• PLC control system, touchscreen.

• Glue-free synchronous belt ensures belt cleanliness.

• Main components are made from materials from renowned German manufacturers, ensuring stable operation.

• Automatic gluing head width adjustment ensures uniform butyl application on both sides thanks to a built-in quick-release control valve.

• Use of a movable vertical butyl feed mechanism and horizontal extrusion is convenient and practical.

• On/off time can be adjusted to suit needs

$0.00

LJZW2020 CNC Bending Machine

LJZW2020 Automatic Frame Bending Machine

Key Features

• Siemens 1200 PLC control system with high operating speed

• 4 storage groups

• Automatic cutting and feeding of aluminum frames

• Automatic pin jam prevention during bending and cutting

• Continuous frame bending

• Aluminum frames available in sizes from 6A to 27A

• Various bending tools for different frame sizes

• Pause and reset device for handling equipment malfunctions

• Curved aluminum frame, smooth stainless steel, heat-resistant spacer

• USB port function for direct reading of Excel files

Key Features

• Siemens 1200 PLC control system with high operating speed

• 4 storage groups

• Automatic cutting and feeding of aluminum frames

• Automatic pin jam prevention during bending and cutting

• Continuous frame bending

• Aluminum frames available in sizes from 6A to 27A

• Various bending tools for different frame sizes

• Pause and reset device for handling equipment malfunctions

• Curved aluminum frame, smooth stainless steel, heat-resistant spacer

• USB port function for direct reading of Excel files

$0.00

LJGZ 2020 Dessicant Filling Machine

LJGZ 2020 Molecular Sieve Frame Filling Machine

Main Features

• Siemens PLC control system

• Molecular sieve size ranges from 0.5mm to 0.9mm

• Simple and intuitive touchscreen interface

• Machine height can be adjusted to suit frame size

• Automatic loading and refilling of molecular sieve

• Dual discharge tubes increase filling speed

• Adjustable filling time

• Automatic drilling, filling, and sealing

• Main components are imported brands

• Filling with large molecular sieve particles

Main Features

• Siemens PLC control system

• Molecular sieve size ranges from 0.5mm to 0.9mm

• Simple and intuitive touchscreen interface

• Machine height can be adjusted to suit frame size

• Automatic loading and refilling of molecular sieve

• Dual discharge tubes increase filling speed

• Adjustable filling time

• Automatic drilling, filling, and sealing

• Main components are imported brands

• Filling with large molecular sieve particles

$0.00

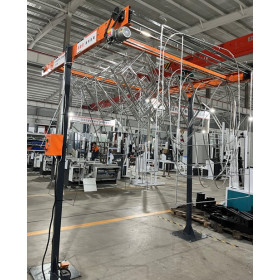

LJSKJ02 Automatic Aluminium Frame Conveyor

LJSKJ02

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

$0.00

EGCNC6133 Automatic Glass Cutting Line

Automatic Glass Cutting Line EGCNC6133.

Jumbo glass format, double-sided loading station, glass cutting table with low-e coating removal option, pneumatic breaking table.

Technical Parameters:

1) Top Size Range: Minimum top size: 2400x1500 mm (single surface);

2) Maximum film top size: 6100x3300 mm;

3) X-Axis Travel Speed: 5~25 m/min (adjustable);

4) Y-Axis Travel Speed: 8~12 m/min (adjustable);

5) Feed Speed: 5-25 m/min (adjustable);

6) Number of Pivot Arms: 12 arms (double pivot);

7) Number of Suction Cups per Arm: Four;

8) Power source: AC 380 V / 50 Hz

9) Total unit power: 8-18.5 kW;

10) Compressed air: 0.6~0.8 MPa

Jumbo glass format, double-sided loading station, glass cutting table with low-e coating removal option, pneumatic breaking table.

Technical Parameters:

1) Top Size Range: Minimum top size: 2400x1500 mm (single surface);

2) Maximum film top size: 6100x3300 mm;

3) X-Axis Travel Speed: 5~25 m/min (adjustable);

4) Y-Axis Travel Speed: 8~12 m/min (adjustable);

5) Feed Speed: 5-25 m/min (adjustable);

6) Number of Pivot Arms: 12 arms (double pivot);

7) Number of Suction Cups per Arm: Four;

8) Power source: AC 380 V / 50 Hz

9) Total unit power: 8-18.5 kW;

10) Compressed air: 0.6~0.8 MPa

$0.00