Главная

There are 204 products.

ZJS-CNC-550x4200 Double Head Cutting Saw CNC

ZJS-CNC-550x4200

550mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

550mm saw blade CNC Double Head Cutting Saw Cutting angle: outside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$22,500.00

ZJS-CNC-500x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-500x4200

500mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

500mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$21,500.00

ZJS-CNC-550x4200 Двухголовая фронтальная пила автомат

ZJS-CNC-550x4200

550mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

550mm saw blade CNC Double Head Cutting Saw Cutting angle: inside 45°and 90°

1. Feature

1. The CNC double head cutting saw adopts Taiwan Delta CNC system, which can complete the continuous

automatic feeding of profiles of different specifications and sizes.

2. The gas-liquid damping cylinder realizes uniform feeding speed regulation and smooth movement.

3. The high-precision spindle makes the saw blade rotate stably.

4. The human-machine interface adopts a color touch screen, which is simple and intuitive.

5. The feeding system adopts imported linear bearing motion pairs, which has high precision and good

stability.

6. The two saw heads can automatically change angles to achieve angle cutting of 45° and 90° profiles.

7. With super long and super short cutting function

$23,500.00

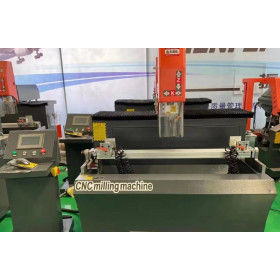

ZSD-CNC-800. CNC Copy Routing Machine

ZSD-CNC-800 CNC COPY ROUTING MACHINE. SINGLE SPINDLE

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

$10,800.00

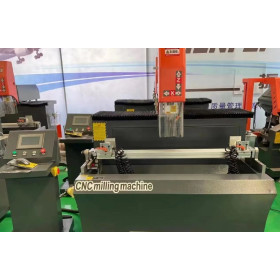

ZSSD-CNC-800. CNC Copy Routing Machine

ZSSD-CNC-800 CNC COPY ROUTING MACHINE. DOUBLE SPINDLE

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

Feature

1. The machine adopts a Chinese brand CNC system, The system comes with a common door and window

hole graphics library, which is more convenient

2. The spindle adopts a high-speed spindle with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The worktable automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the worktable, which is efficient and accurate.

5.There is a 1.5m long support rack on the right side of the machine

$12,350.00

ZSSD-CNC-3000. CNC Copy Routing Machine 3000 mm

ZSSD-CNC-3000 CNC COPY ROUTING MACHINE. DOUBLE SPINDLE

Feature

1. The machine adopts Taiwan DELTA CNC system, which can complete the hole and groove processing of

the cabinet door hinge in one clamping.

2. The dual spindles use high-speed spindles with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The processing G code is automatically converted through the programming software, which is simple to

operate, efficient and low in labor intensity.

5. The workbench automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the workbench, which is efficient and accurate

Feature

1. The machine adopts Taiwan DELTA CNC system, which can complete the hole and groove processing of

the cabinet door hinge in one clamping.

2. The dual spindles use high-speed spindles with high precision, good safety and high reliability.

3. The X-axis adopts high-precision helical gears and helical rack transmission, and the Y-axis and Z-axis

adopt high-precision ball screw transmission, which has stable transmission and high precision.

4. The processing G code is automatically converted through the programming software, which is simple to

operate, efficient and low in labor intensity.

5. The workbench automatically reverses -90°, 0°, 90°, and the profile can be clamped once to achieve

three-sided processing. When processing deep through holes (special-shaped holes), deep hole processing is

achieved by flipping the workbench, which is efficient and accurate

$31,000.00

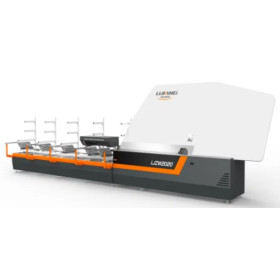

ZFHD-CNC-3000 Aluminum CNC Machining Center With Automatic Tool Change

ZFHD-CNC-3000 Aluminum CNC Machining Center With Automatic Tool Change

Feature

1. Used for drilling/milling grooves/round holes/special-shaped holes/plane engraving and other processing

of aluminum alloy profiles.

2. The machine adopts Delta CNC system, which can complete continuous automatic milling of profiles of

different specifications and sizes.

3. The system comes with CAM, which makes editing hole types more intuitive and simple, and

automatically converts processing G codes, which is simple to operate, efficient and low in labor intensity.

4. CAD graphics can be imported and processed directly after editing.

Feature

1. Used for drilling/milling grooves/round holes/special-shaped holes/plane engraving and other processing

of aluminum alloy profiles.

2. The machine adopts Delta CNC system, which can complete continuous automatic milling of profiles of

different specifications and sizes.

3. The system comes with CAM, which makes editing hole types more intuitive and simple, and

automatically converts processing G codes, which is simple to operate, efficient and low in labor intensity.

4. CAD graphics can be imported and processed directly after editing.

$65,000.00

LBP2500Q IG LINE 2,5 m

Automatic insulating glass machine Q Series (Machinery of this series is with argon gas filling on-line)

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, inner-panel assembly, argon gas filling & press section and output section (title table), adopts advanced IG manufacture technology and craft . This production line can fill argon gas during pressing into insulating glass.

Model: LBP1800Q / LBP2000Q / LBP2500Q / LBP2850Q / LBP3000Q / LBP3300Q

This production line, which includes glass loading section, washing and drying machine, conveyor section, light inspection and aluminum frame location section, inner-panel assembly, argon gas filling & press section and output section (title table), adopts advanced IG manufacture technology and craft . This production line can fill argon gas during pressing into insulating glass.

Model: LBP1800Q / LBP2000Q / LBP2500Q / LBP2850Q / LBP3000Q / LBP3300Q

$0.00

LJBZ2540 INSULATING GLASS UNIT ASSEMBLY LINE

LJBZ2540 Automatic Vertical Insulating Glass Assembly Line

Features

• Siemens PLC control system (Germany), touchscreen interface

• Automatic detection of coated and low-e glass

• 3 pairs of soft brushes for online and offline washing of low-e glass

• The washing machine uses stainless steel and is waterproof

• Air heating system

• Automatic fan start and stop

• Noise reduction system

• Online washing speed display

• Intelligent intermittent operation mode, energy saving

• Adjustable pressure plate to maintain a flat pressure surface

• Automatic gas filling: gas concentration can be set and the filling process is displayed online at high gas concentrations

• Connection via aviation plug

• Designed for the production of single-chamber, double-chamber, and structural (stepped) glass double-glazed windows

Features

• Siemens PLC control system (Germany), touchscreen interface

• Automatic detection of coated and low-e glass

• 3 pairs of soft brushes for online and offline washing of low-e glass

• The washing machine uses stainless steel and is waterproof

• Air heating system

• Automatic fan start and stop

• Noise reduction system

• Online washing speed display

• Intelligent intermittent operation mode, energy saving

• Adjustable pressure plate to maintain a flat pressure surface

• Automatic gas filling: gas concentration can be set and the filling process is displayed online at high gas concentrations

• Connection via aviation plug

• Designed for the production of single-chamber, double-chamber, and structural (stepped) glass double-glazed windows

$0.00

LJTJ2540 CNC Sealing Robot

Vertical Insulating Glass Sealing Robot

Model LJTJ2540

Main Features:

• Japanese Yaskawa servo control system, 8 axes, 7 sets of servo drives, fully automatic and highly efficient sealing machine

• 4 sections, glass storage option

• Toothed belt drive, smooth transmission and precise positioning

• Automatic glass corner sealing with a scraper and roller

• Automatic glass size and adhesive depth measurement

• All automatic functions are manually controlled

• Capable of coating double/triple glazing

• One booster pump set controls two sealant groups (optional)

• Suitable for silicone, polysulfide, and silicone structural sealants

• Can be connected to an insulating glass processing line

Model LJTJ2540

Main Features:

• Japanese Yaskawa servo control system, 8 axes, 7 sets of servo drives, fully automatic and highly efficient sealing machine

• 4 sections, glass storage option

• Toothed belt drive, smooth transmission and precise positioning

• Automatic glass corner sealing with a scraper and roller

• Automatic glass size and adhesive depth measurement

• All automatic functions are manually controlled

• Capable of coating double/triple glazing

• One booster pump set controls two sealant groups (optional)

• Suitable for silicone, polysulfide, and silicone structural sealants

• Can be connected to an insulating glass processing line

$0.00

LJTB01 BUTYL EXTRUDER

LJTB01 Butyl Extruder

Key Features:

Butyl extrusion speed can reach 47 m/min.

• Butyl savings compared to conventional equipment: adhesive consumption reaches 7 g/m.

• Automatic exhaust function ensures continuous butyl application.

• PLC control system, touchscreen.

• Glue-free synchronous belt ensures belt cleanliness.

• Main components are made from materials from renowned German manufacturers, ensuring stable operation.

• Automatic gluing head width adjustment ensures uniform butyl application on both sides thanks to a built-in quick-release control valve.

• Use of a movable vertical butyl feed mechanism and horizontal extrusion is convenient and practical.

• On/off time can be adjusted to suit needs

Key Features:

Butyl extrusion speed can reach 47 m/min.

• Butyl savings compared to conventional equipment: adhesive consumption reaches 7 g/m.

• Automatic exhaust function ensures continuous butyl application.

• PLC control system, touchscreen.

• Glue-free synchronous belt ensures belt cleanliness.

• Main components are made from materials from renowned German manufacturers, ensuring stable operation.

• Automatic gluing head width adjustment ensures uniform butyl application on both sides thanks to a built-in quick-release control valve.

• Use of a movable vertical butyl feed mechanism and horizontal extrusion is convenient and practical.

• On/off time can be adjusted to suit needs

$0.00

LJZW2020 CNC Bending Machine

LJZW2020 Automatic Frame Bending Machine

Key Features

• Siemens 1200 PLC control system with high operating speed

• 4 storage groups

• Automatic cutting and feeding of aluminum frames

• Automatic pin jam prevention during bending and cutting

• Continuous frame bending

• Aluminum frames available in sizes from 6A to 27A

• Various bending tools for different frame sizes

• Pause and reset device for handling equipment malfunctions

• Curved aluminum frame, smooth stainless steel, heat-resistant spacer

• USB port function for direct reading of Excel files

Key Features

• Siemens 1200 PLC control system with high operating speed

• 4 storage groups

• Automatic cutting and feeding of aluminum frames

• Automatic pin jam prevention during bending and cutting

• Continuous frame bending

• Aluminum frames available in sizes from 6A to 27A

• Various bending tools for different frame sizes

• Pause and reset device for handling equipment malfunctions

• Curved aluminum frame, smooth stainless steel, heat-resistant spacer

• USB port function for direct reading of Excel files

$0.00

LJGZ 2020 Dessicant Filling Machine

LJGZ 2020 Molecular Sieve Frame Filling Machine

Main Features

• Siemens PLC control system

• Molecular sieve size ranges from 0.5mm to 0.9mm

• Simple and intuitive touchscreen interface

• Machine height can be adjusted to suit frame size

• Automatic loading and refilling of molecular sieve

• Dual discharge tubes increase filling speed

• Adjustable filling time

• Automatic drilling, filling, and sealing

• Main components are imported brands

• Filling with large molecular sieve particles

Main Features

• Siemens PLC control system

• Molecular sieve size ranges from 0.5mm to 0.9mm

• Simple and intuitive touchscreen interface

• Machine height can be adjusted to suit frame size

• Automatic loading and refilling of molecular sieve

• Dual discharge tubes increase filling speed

• Adjustable filling time

• Automatic drilling, filling, and sealing

• Main components are imported brands

• Filling with large molecular sieve particles

$0.00

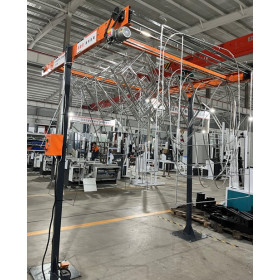

LJSKJ02 Automatic Aluminium Frame Conveyor

LJSKJ02

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

$0.00

DS-ICT3826-A Multipurpose Integrated Glass Cutting Table

DS-ICT3826-A Multifunctional Glass Cutting Table

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

$0.00

DS-ICT3826-A-B-T Integrated Glass Cutting Table

DS-ICT3826-A-B-T Multifunctional Glass Cutting Table

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

$0.00

YR-AD4228 CNC Glass Cutting Line

YR-AD4228 Automatic Glass Cutting Line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

The Yinrui YN Series cutting system delivers high-precision cutting and superior edge performance, significantly reducing grinding wheel consumption in subsequent edging stages. This improvement reduces production costs while improving edge quality and productivity.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

The Yinrui YN Series cutting system delivers high-precision cutting and superior edge performance, significantly reducing grinding wheel consumption in subsequent edging stages. This improvement reduces production costs while improving edge quality and productivity.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

$0.00

DS-CM4228-D1 Automatic Glass Cutting Line

DS-CM4228-D1

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

$0.00

DS-CM6133-D1 Automatic Glass Cutting Line

DS-CM6133-D1

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 6100×3300 mm to 18000×330

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 6100×3300 mm to 18000×330

$0.00