Главная

There are 10 products.

USED ODR PROVEDAL C-640, 2010

USED ODR PROVEDAL C-640, 2010 YEAR OF PRODUCTION. PNEUMATIC PRESS WITH A DIE FOR SLIDING, SPAIN

Pneumatic press with a matrix for the production of aluminum sliding structures of the PROVEDAL C-640 system. ODR, Spain. In excellent condition. Year of manufacture 2010. Location - Samara.

Pneumatic press with a matrix for the production of aluminum sliding structures of the PROVEDAL C-640 system. ODR, Spain. In excellent condition. Year of manufacture 2010. Location - Samara.

$1,750.00

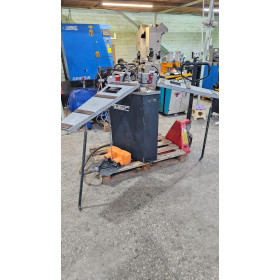

copy of OZGENC OMRM136, 2014. Corner Crimping Machine

Pneumatic corner crimping press for joining corners of aluminum structures. Manufacturer OZGENC, Turkey. Model OMRM 136. Year of manufacture 2014. Condition is excellent. Included - pedals, side supports, knives. Warehouse storage. Can be connected and checked. Location - Samara. Shipment - pickup, delivery by a transport company is possible.

$5,300.00

NEW OZCELIK VEGA-IIA Single Head Saw

NEW OZCELIK VEGA-IIA_AUTOMATIC SINGLE-HEAD PENDULUM SAW

Single-head aluminum saw Ozcelik Vega II A 400 with pendulum feed of the saw blade and coolant supply system, which is designed for cutting aluminum profiles and non-ferrous metals. Automatic feed of the saw blade. Cutting safety is ensured by a double spring system and a protective cover.

The cutting angle can be changed within the range from -45° to the right to +45° to the left. The main angles -45°, -30°, -22.5°, -15°, 0°, 15°, 22.5°, 30°, 45° have a clear fixation, other intermediate angles are set according to a graduated scale. The workpiece is fixed on the vega-2 thanks to two vertical and two horizontal pneumatic clamps.

THE PRICE OF THE MACHINE INCLUDES A 3.0 M MEASURING ROLLER UNIT.

Single-head aluminum saw Ozcelik Vega II A 400 with pendulum feed of the saw blade and coolant supply system, which is designed for cutting aluminum profiles and non-ferrous metals. Automatic feed of the saw blade. Cutting safety is ensured by a double spring system and a protective cover.

The cutting angle can be changed within the range from -45° to the right to +45° to the left. The main angles -45°, -30°, -22.5°, -15°, 0°, 15°, 22.5°, 30°, 45° have a clear fixation, other intermediate angles are set according to a graduated scale. The workpiece is fixed on the vega-2 thanks to two vertical and two horizontal pneumatic clamps.

THE PRICE OF THE MACHINE INCLUDES A 3.0 M MEASURING ROLLER UNIT.

$0.00

FIMTEC SD25/S4 Double Head Cutting Saw (automatic)

Double-head automatic front saw FIMTEC SD25/S4. Designed for cutting two PVC or aluminum profiles at the same time. Saw blades 500 mm, in good condition. The cut length of workpieces at 90 and 45 degrees corresponds to the standard, no errors or backlashes are observed. Cutting at an angle is also within the standard, the angles after cutting match the specified parameters.

The machine is located in our warehouse in Samara, is not in serial operation, completely put in order both technically and in terms of appearance. Upon request, we are ready to send photos and videos, organize a video call with the warehouse, and also connect and show the equipment in operation with tests on the client's samples, if there is a desire to come in person and see everything.

We will help with loading onto your transport, we can also help with finding additional cargo. There is a forklift at the base, there will be no problems with sending.

The machine is located in our warehouse in Samara, is not in serial operation, completely put in order both technically and in terms of appearance. Upon request, we are ready to send photos and videos, organize a video call with the warehouse, and also connect and show the equipment in operation with tests on the client's samples, if there is a desire to come in person and see everything.

We will help with loading onto your transport, we can also help with finding additional cargo. There is a forklift at the base, there will be no problems with sending.

$12,800.00

DS-ICT3826-A Multipurpose Integrated Glass Cutting Table

DS-ICT3826-A Multifunctional Glass Cutting Table

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

$0.00

DS-ICT3826-A-B-T Integrated Glass Cutting Table

DS-ICT3826-A-B-T Multifunctional Glass Cutting Table

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

Integrated glass cutting table: it combines three functions: loading, cutting, and

breaking glass. It has a smaller footprint, more features, and is flexible and convenient!

The operating process is as follows: the rotating arm flips over and extends forward. Upon contact with the glass, the suction cup begins to pick up the glass. Once a vacuum is achieved, the suction cup arm retracts and lowers. The glass is placed horizontally on the work table. The fan turns on, the positioning stand rises, bringing the glass closer to the positioning stand. The fan then turns off, and the positioning stand lowers, after which cutting begins. After the glass is cut, the fan turns on to break the glass on the work table. The glass is separated into small pieces using a breaking rod. The small pieces are removed, the work table is cleared, and then the next cycle begins.

$0.00

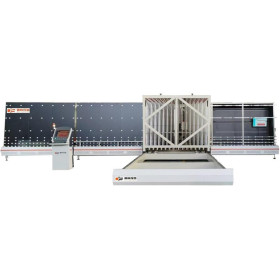

DS-CM4228-D1 Automatic Glass Cutting Line

DS-CM4228-D1

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 4200×2800 mm to 18000×330

$0.00

DS-CM6133-D1 Automatic Glass Cutting Line

DS-CM6133-D1

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 6100×3300 mm to 18000×330

Automatic glass cutting line.

Complete set consisting of a loading station, glass cutting table, and glass breaking table.

Technical Specifications

1) Cutting speed - 180 m/min

2) Cutting acceleration - 6-8 m/s²

3) Linear accuracy - ±0.15 mm

4) Perimeter cutting accuracy - ±0.2 mm

5) Diagonal accuracy - ±0.35 mm/m²

6) Cutting thickness range - 3-19 mm

7) Glass format - from 6100×3300 mm to 18000×330

$0.00

DISAI DS-LP2520-90 Intelligent Glass Sorting System

DISAI DS-LP2520-90 Intelligent Glass Sorting System

DISAI DS-LP2520-90 Intelligent Glass Sorting System

Description

Vertical glass sorting station: Its primary function is to sort cut glass by customer name, size, and type, and correctly label it for easy identification.

Operating process: Start the equipment, place each glass on the receiving table, and then transfer it to the measuring table (the code has been scanned or the size has been measured during the transfer process, and the glass has been identified). Different glasses will be placed in different bins, and once all the glasses are in the bins, workers can choose how to remove them from the bin. Sorting can be performed by customer, by size, by glass type, or in pairs with specific bins.

DISAI DS-LP2520-90 Intelligent Glass Sorting System

Description

Vertical glass sorting station: Its primary function is to sort cut glass by customer name, size, and type, and correctly label it for easy identification.

Operating process: Start the equipment, place each glass on the receiving table, and then transfer it to the measuring table (the code has been scanned or the size has been measured during the transfer process, and the glass has been identified). Different glasses will be placed in different bins, and once all the glasses are in the bins, workers can choose how to remove them from the bin. Sorting can be performed by customer, by size, by glass type, or in pairs with specific bins.

$0.00

DISAI DS-DR-ISS4228-AB6 Интеллектуальная система хранения листового стекла

DS-DR-ISS4228-AB6 Intelligent Sheet Glass Storage System

SYSTEM DESCRIPTION

Intelligent Glass Storage System: The DISAI intelligent drawer-type glass storage system consists of four components: a glass rack, chassis, power unit, protective net, and control system. It can record the type and quantity of glass in each rack and quickly switch between glass types for efficient production.

Storage system functionality:

1) Can be connected to an office ERP system for real-time inventory data transfer.

2) Easily handle glass of various sizes.

3) The quantity and type of glass in the warehouse can be tracked at any time.

4) Can improve glass production productivity and reduce waste.

5) Increases production efficiency and reduces glass handling time.

SYSTEM DESCRIPTION

Intelligent Glass Storage System: The DISAI intelligent drawer-type glass storage system consists of four components: a glass rack, chassis, power unit, protective net, and control system. It can record the type and quantity of glass in each rack and quickly switch between glass types for efficient production.

Storage system functionality:

1) Can be connected to an office ERP system for real-time inventory data transfer.

2) Easily handle glass of various sizes.

3) The quantity and type of glass in the warehouse can be tracked at any time.

4) Can improve glass production productivity and reduce waste.

5) Increases production efficiency and reduces glass handling time.

$0.00