Главная

There are 25 products.

LJTB01 BUTYL EXTRUDER

LJTB01 Butyl Extruder

Key Features:

Butyl extrusion speed can reach 47 m/min.

• Butyl savings compared to conventional equipment: adhesive consumption reaches 7 g/m.

• Automatic exhaust function ensures continuous butyl application.

• PLC control system, touchscreen.

• Glue-free synchronous belt ensures belt cleanliness.

• Main components are made from materials from renowned German manufacturers, ensuring stable operation.

• Automatic gluing head width adjustment ensures uniform butyl application on both sides thanks to a built-in quick-release control valve.

• Use of a movable vertical butyl feed mechanism and horizontal extrusion is convenient and practical.

• On/off time can be adjusted to suit needs

Key Features:

Butyl extrusion speed can reach 47 m/min.

• Butyl savings compared to conventional equipment: adhesive consumption reaches 7 g/m.

• Automatic exhaust function ensures continuous butyl application.

• PLC control system, touchscreen.

• Glue-free synchronous belt ensures belt cleanliness.

• Main components are made from materials from renowned German manufacturers, ensuring stable operation.

• Automatic gluing head width adjustment ensures uniform butyl application on both sides thanks to a built-in quick-release control valve.

• Use of a movable vertical butyl feed mechanism and horizontal extrusion is convenient and practical.

• On/off time can be adjusted to suit needs

$0.00

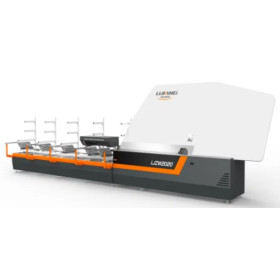

LJZW2020 CNC Bending Machine

LJZW2020 Automatic Frame Bending Machine

Key Features

• Siemens 1200 PLC control system with high operating speed

• 4 storage groups

• Automatic cutting and feeding of aluminum frames

• Automatic pin jam prevention during bending and cutting

• Continuous frame bending

• Aluminum frames available in sizes from 6A to 27A

• Various bending tools for different frame sizes

• Pause and reset device for handling equipment malfunctions

• Curved aluminum frame, smooth stainless steel, heat-resistant spacer

• USB port function for direct reading of Excel files

Key Features

• Siemens 1200 PLC control system with high operating speed

• 4 storage groups

• Automatic cutting and feeding of aluminum frames

• Automatic pin jam prevention during bending and cutting

• Continuous frame bending

• Aluminum frames available in sizes from 6A to 27A

• Various bending tools for different frame sizes

• Pause and reset device for handling equipment malfunctions

• Curved aluminum frame, smooth stainless steel, heat-resistant spacer

• USB port function for direct reading of Excel files

$0.00

LJGZ 2020 Dessicant Filling Machine

LJGZ 2020 Molecular Sieve Frame Filling Machine

Main Features

• Siemens PLC control system

• Molecular sieve size ranges from 0.5mm to 0.9mm

• Simple and intuitive touchscreen interface

• Machine height can be adjusted to suit frame size

• Automatic loading and refilling of molecular sieve

• Dual discharge tubes increase filling speed

• Adjustable filling time

• Automatic drilling, filling, and sealing

• Main components are imported brands

• Filling with large molecular sieve particles

Main Features

• Siemens PLC control system

• Molecular sieve size ranges from 0.5mm to 0.9mm

• Simple and intuitive touchscreen interface

• Machine height can be adjusted to suit frame size

• Automatic loading and refilling of molecular sieve

• Dual discharge tubes increase filling speed

• Adjustable filling time

• Automatic drilling, filling, and sealing

• Main components are imported brands

• Filling with large molecular sieve particles

$0.00

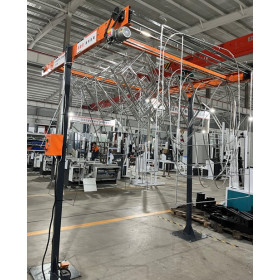

LJSKJ02 Automatic Aluminium Frame Conveyor

LJSKJ02

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

Automatic conveyor for moving filled assembled aluminum frames to the glass unit assembly area on the line.

Standard machine.

$0.00

EGCNC6133 Automatic Glass Cutting Line

Automatic Glass Cutting Line EGCNC6133.

Jumbo glass format, double-sided loading station, glass cutting table with low-e coating removal option, pneumatic breaking table.

Technical Parameters:

1) Top Size Range: Minimum top size: 2400x1500 mm (single surface);

2) Maximum film top size: 6100x3300 mm;

3) X-Axis Travel Speed: 5~25 m/min (adjustable);

4) Y-Axis Travel Speed: 8~12 m/min (adjustable);

5) Feed Speed: 5-25 m/min (adjustable);

6) Number of Pivot Arms: 12 arms (double pivot);

7) Number of Suction Cups per Arm: Four;

8) Power source: AC 380 V / 50 Hz

9) Total unit power: 8-18.5 kW;

10) Compressed air: 0.6~0.8 MPa

Jumbo glass format, double-sided loading station, glass cutting table with low-e coating removal option, pneumatic breaking table.

Technical Parameters:

1) Top Size Range: Minimum top size: 2400x1500 mm (single surface);

2) Maximum film top size: 6100x3300 mm;

3) X-Axis Travel Speed: 5~25 m/min (adjustable);

4) Y-Axis Travel Speed: 8~12 m/min (adjustable);

5) Feed Speed: 5-25 m/min (adjustable);

6) Number of Pivot Arms: 12 arms (double pivot);

7) Number of Suction Cups per Arm: Four;

8) Power source: AC 380 V / 50 Hz

9) Total unit power: 8-18.5 kW;

10) Compressed air: 0.6~0.8 MPa

$0.00