YILMAZ MACHINE UPVC & ALUM

There are 12 products.

YILMAZ ALM 6510 Cutting&Milling Center Aluminium

ALM 6510 is 8-axis CNC controlled machining center which is specifically designed to process any kind of aluminium profiles in the market. The machine can do all operations on four sides of aluminium profiles such as milling, opening key holes, hinge holes, handle holes, marking, saw blade cutting etc. ALM 6510 has the programming feature which provides minimum waste and maximum amount of production. 7 pieces of aluminium profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. The cutting unit can perform serial cutting of profiles in the range of 45⁰-135°. Operator attaches barcodes on the processed profiles to make them ready for crimping operation.

$0.00

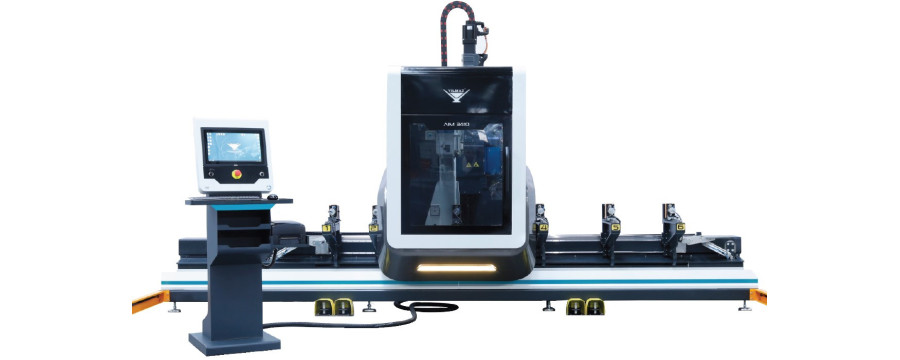

YILMAZ AIM 3410 4-Axis Machining Center

AIM 3410 is a 4-axis CNC machine designed specifically for processing all types of aluminum and PVC profiles, low carbon alloys and thin-walled steel profiles available in the market. Thanks to the 4th axis function, it can also machine 3 profile surfaces. Quick tool changes are ensured by a mobile in-line magazine equipped with 8 standard tools. To minimize tool change time, the tool magazine was designed on the moving Y axis of the machine.

$0.00

YILMAZ AIM 7510 CNC Machining Center 5-Axis

AIM 7510 is 5-axis servo-controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminium & PVC profiles, light alloys in general and thin walled steel profiles.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

$0.00

YILMAZ AIM 4420 / 7420 CNC Machining Center 4-Axis

YILMAZ AIM 4420 / 7420 4-AXIS MACHINING CENTER FOR ALUMINUM PROFILES

AIM 4420-7420 is a 4-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles, as well as low-carbon, thin-walled steel profiles used in the market. AIM 4420 : 4 m. - AIM 7420: 7 m.

PRICE ON REQUEST

AIM 4420-7420 is a 4-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles, as well as low-carbon, thin-walled steel profiles used in the market. AIM 4420 : 4 m. - AIM 7420: 7 m.

PRICE ON REQUEST

$0.00

YILMAZ DK 502 Double Head Welding Machine

YILMAZ DK 502 TWO-HEAD WELDING MACHINE FOR PVC PROFILES

TWO-HEAD WELDING MACHINE YILMAZ DK-502 It is used to connect two corners of a PVC profile by welding.

• Performs a fully automatic procedure for welding PVC profiles at an angle of 90°

• Possibility of precise welding on the left block at angles from 130° to 180°.

• All parameters such as melting and gluing time, welding pressure can be adjusted from the control panel

• Precise welding is ensured thanks to the linear guide mechanism • Two corners of PVC frame and sash profiles are welded in one operation

• Teflon winding system allows practical replacement of Teflon

• Practical system for replacing the welding form prevents loss of time

• Possibility of adjusting the clamp and gluing pressure depending on the type of profile

• Temperature adjustment from 0° to 300°C thanks to the electronic thermostat

TWO-HEAD WELDING MACHINE YILMAZ DK-502 It is used to connect two corners of a PVC profile by welding.

• Performs a fully automatic procedure for welding PVC profiles at an angle of 90°

• Possibility of precise welding on the left block at angles from 130° to 180°.

• All parameters such as melting and gluing time, welding pressure can be adjusted from the control panel

• Precise welding is ensured thanks to the linear guide mechanism • Two corners of PVC frame and sash profiles are welded in one operation

• Teflon winding system allows practical replacement of Teflon

• Practical system for replacing the welding form prevents loss of time

• Possibility of adjusting the clamp and gluing pressure depending on the type of profile

• Temperature adjustment from 0° to 300°C thanks to the electronic thermostat

$0.00

YILMAZ TK 503 Single Head Welding Machine

YILMAZ TK 503 SINGLE-HEAD WELDING MACHINE FOR PVC PROFILES

TK 503. Single-head welding machine

•Possibility of alternate compression of the profile with each press of the foot pedal.

•Possibility of adjusting the pressure and melting period according to the type of profile.

•Forming plates with adjustable distance for lower and upper welding.

•After compression of the profiles, the welding process is performed automatically.

•Adjustable thermostat, which can be adjusted to the required temperature from 0° to 260° C.

•Min. 1.5mm melting thickness.

•After fixing the profiles, welding is performed automatically.

•The mechanism is manufactured according to CE.

Specifications:

TK 503 1.5 kW, 230 V, 50 Hz h = 130 mm max, a = 30 ° - 180 ° 6-8 bar, 20 l / min 630 x 620 x 1400 mm 115-143 kg

TK 503. Single-head welding machine

•Possibility of alternate compression of the profile with each press of the foot pedal.

•Possibility of adjusting the pressure and melting period according to the type of profile.

•Forming plates with adjustable distance for lower and upper welding.

•After compression of the profiles, the welding process is performed automatically.

•Adjustable thermostat, which can be adjusted to the required temperature from 0° to 260° C.

•Min. 1.5mm melting thickness.

•After fixing the profiles, welding is performed automatically.

•The mechanism is manufactured according to CE.

Specifications:

TK 503 1.5 kW, 230 V, 50 Hz h = 130 mm max, a = 30 ° - 180 ° 6-8 bar, 20 l / min 630 x 620 x 1400 mm 115-143 kg

$0.00

YILMAZ TK 505 Single Head Welding Machine

YILMAZ TK 505 SINGLE-HEAD WELDING MACHINE FOR PVC PROFILES

SINGLE-HEAD WELDING MACHINE YILMAZ TK505 Designed for welding corners of colored and laminated PVC profiles.

"Zero seam" - 0-0.2 mm. Allows you to clean the weld with one chisel. Allows you to adjust the clamping and compression pressure. Welded angles from 30 to 180 °.

Melting temperature from 0 to 260 °.

After pressing the profiles - the welding process is automatic. Convenient control via the pedal.

Fully electronic control of the temperature and melting time.

SINGLE-HEAD WELDING MACHINE YILMAZ TK505 Designed for welding corners of colored and laminated PVC profiles.

"Zero seam" - 0-0.2 mm. Allows you to clean the weld with one chisel. Allows you to adjust the clamping and compression pressure. Welded angles from 30 to 180 °.

Melting temperature from 0 to 260 °.

After pressing the profiles - the welding process is automatic. Convenient control via the pedal.

Fully electronic control of the temperature and melting time.

$0.00

YILMAZ NCR300 CNC Copy Router

YILMAZ NCR300 CNC COPY MILLING MACHINE WITH ROTARY TABLE, WITH COOLING

NCR300 - Powerful copy milling machine for aluminum and PVC with rotary table. The machine with pantograph is designed for fast and precise processing of 3 sides of aluminum profile: making cavities on doors and sashes, holes for locks and handles, as well as bolts.

• The machine is equipped with a rotating tabletop for processing 3 profile surfaces at angles of -90°/0°/+90°

• Tabletop brake mechanism, providing the ability to process at intermediate angles from -90° to 90° and fixing the tabletop

• High-performance 2.2 kW motor • Possibility of processing at 90°: (X) 585 mm, (Y) 200 mm, (Z) 200 mm

• Possibility of using a cutter with a diameter of 5 mm, 8 mm and 10 mm.

• Easily adjustable pneumatic 3-stage feelers Ø5, Ø8 and Ø10 mm.

NCR300 - Powerful copy milling machine for aluminum and PVC with rotary table. The machine with pantograph is designed for fast and precise processing of 3 sides of aluminum profile: making cavities on doors and sashes, holes for locks and handles, as well as bolts.

• The machine is equipped with a rotating tabletop for processing 3 profile surfaces at angles of -90°/0°/+90°

• Tabletop brake mechanism, providing the ability to process at intermediate angles from -90° to 90° and fixing the tabletop

• High-performance 2.2 kW motor • Possibility of processing at 90°: (X) 585 mm, (Y) 200 mm, (Z) 200 mm

• Possibility of using a cutter with a diameter of 5 mm, 8 mm and 10 mm.

• Easily adjustable pneumatic 3-stage feelers Ø5, Ø8 and Ø10 mm.

$0.00

YILMAZ ST 264 Water Slot Milling Machine

YILMAZ ST 264 MACHINE FOR MILLING WATER SLOTS

THREE-SPINDLE AUTOMATIC MACHINE FOR MILLING DRAINAGE CHANNELS YILMAZ ST264 Designed for milling drainage channels of various heights in PVC profiles in two or three directions at various angles.

Contains 3 motors of 600 W each. The motor is selected using a switch. Automatic centering along the profile axis. Automatic processing cycle, one-button start. Included: 5x25x80/8 cutters - 2 pcs., 5x18x60/8 cutter - 1 pc., blow gun.

THREE-SPINDLE AUTOMATIC MACHINE FOR MILLING DRAINAGE CHANNELS YILMAZ ST264 Designed for milling drainage channels of various heights in PVC profiles in two or three directions at various angles.

Contains 3 motors of 600 W each. The motor is selected using a switch. Automatic centering along the profile axis. Automatic processing cycle, one-button start. Included: 5x25x80/8 cutters - 2 pcs., 5x18x60/8 cutter - 1 pc., blow gun.

$0.00

YILMAZ CRM250S Copy-Router

YILMAZ CRM250S PNEUMATIC COPY MILLING MACHINE WITH COOLING

CRM 250 S - Manual copy milling machine for aluminum and PVC The machine with a pantograph is designed for fast and precise processing of 3 sides of an aluminum profile: making cavities on doors and sashes, holes for locks and handles, as well as bolts.

• The machine is equipped with a rotating tabletop for processing 3 profile surfaces at angles of -90°/0°/+90°

STANDARD COMPONENTS

• Ø8 x L: 120 mm cutter tooth

• Spray cooling system for the router kit

• Sprayer

• Right and left profile support

• Maintenance key (24 mm)

• Nippers

• Copy template

• LED lighting system

• 4x horizontal clamp

CRM 250 S - Manual copy milling machine for aluminum and PVC The machine with a pantograph is designed for fast and precise processing of 3 sides of an aluminum profile: making cavities on doors and sashes, holes for locks and handles, as well as bolts.

• The machine is equipped with a rotating tabletop for processing 3 profile surfaces at angles of -90°/0°/+90°

STANDARD COMPONENTS

• Ø8 x L: 120 mm cutter tooth

• Spray cooling system for the router kit

• Sprayer

• Right and left profile support

• Maintenance key (24 mm)

• Nippers

• Copy template

• LED lighting system

• 4x horizontal clamp

$0.00

YILMAZ FR 226S Automatic Copy Router with Tripple Drilling

YILMAZ FR 226S COPY MILLING MACHINE WITH 3-SPINDLE HEAD (HOLES FOR HANDLES AND LOCKS)

AUTOMATIC COPY MILLING MACHINE YILMAZ FR226S.

Designed for milling holes for locks and handles in PVC and AL profiles. Makes holes in different directions. Pneumatic profile clamp. Automatic feed of the three-spindle drilling head. Manual milling according to the copy. Included: cutter 5x25x80/8 - 1 pc., drills p10-l12-p10 with chamfer - 1 set, blow gun.

Yilmaz FR 226 is a copy-milling machine for making all technological holes in a PVC profile: lock cylinder, hardware groove, holes for hardware handles, drainage holes, etc. Thanks to the low-speed drilling head of 900 rpm, it is possible to drill PVC simultaneously with reinforcement.

Automatic movement of the drilling head is provided by a hydropneumatic feed with the ability to adjust. Two horizontal pneumatic clamps are used to fix the profile. The machine can also be equipped with a profile centering system or a measuring roller table system.

AUTOMATIC COPY MILLING MACHINE YILMAZ FR226S.

Designed for milling holes for locks and handles in PVC and AL profiles. Makes holes in different directions. Pneumatic profile clamp. Automatic feed of the three-spindle drilling head. Manual milling according to the copy. Included: cutter 5x25x80/8 - 1 pc., drills p10-l12-p10 with chamfer - 1 set, blow gun.

Yilmaz FR 226 is a copy-milling machine for making all technological holes in a PVC profile: lock cylinder, hardware groove, holes for hardware handles, drainage holes, etc. Thanks to the low-speed drilling head of 900 rpm, it is possible to drill PVC simultaneously with reinforcement.

Automatic movement of the drilling head is provided by a hydropneumatic feed with the ability to adjust. Two horizontal pneumatic clamps are used to fix the profile. The machine can also be equipped with a profile centering system or a measuring roller table system.

$0.00

YILMAZ FR 221S Copy Router

YILMAZ FR 221 S ALUMINUM. COPY MILLING MACHINE WITH COOLING

SINGLE SPINDLE COPY MILLING MACHINE YILMAZ FR221S Designed for milling holes for locks and handles in PVC and AL profiles. Makes holes in different directions. Pneumatic profile clamps. Included: cutters, blow gun, cooling system.

CHARACTERISTICS

Power 800 W (220 V) 1200 W (380 V)

Dimensions 80x64x149 cm

Weight 76 kg

Rotation speed 14000 rpm

SINGLE SPINDLE COPY MILLING MACHINE YILMAZ FR221S Designed for milling holes for locks and handles in PVC and AL profiles. Makes holes in different directions. Pneumatic profile clamps. Included: cutters, blow gun, cooling system.

CHARACTERISTICS

Power 800 W (220 V) 1200 W (380 V)

Dimensions 80x64x149 cm

Weight 76 kg

Rotation speed 14000 rpm

$0.00