Главная

There are 183 products.

FENSTEK CCM120 Corner Crimping Machine 120 mm (pneumatic)

CCM120 CORNER CRIMPING MACHINE 120 mm

Aluminum Window Corner Crimping Machine

Features:

1. Aluminum corner crimper mainly used for crimping the 90 corner of aluminum window and door

2. Adopt new mechanical linkage device ,realized complete synchronous corner combining

3. Adjustable locating device suitable for various sections and sizes processing

4. Left and right punching heads adopt hard synchronous feeding device ,thus avoideduseless deformation and made the connection more firmly.

5. Easy machine setting due to the synchronous feeding device.

Aluminum Window Corner Crimping Machine

Features:

1. Aluminum corner crimper mainly used for crimping the 90 corner of aluminum window and door

2. Adopt new mechanical linkage device ,realized complete synchronous corner combining

3. Adjustable locating device suitable for various sections and sizes processing

4. Left and right punching heads adopt hard synchronous feeding device ,thus avoideduseless deformation and made the connection more firmly.

5. Easy machine setting due to the synchronous feeding device.

$12,700.00

SINON LZJ03-130 Corner Crimping Machine, 130 mm

LZJ03-130 CORNER CRIMPING MACHINE. 130MM

LZJ03-130. Angle crimping press for aluminum profiles, suitable for all kinds of aluminum alloy doors and windows, including thermal break profiles and ordinary aluminum profiles

Main Features

Universal corner crimping machine for aluminum profiles. The hydraulic system has the advantages of high power, wide range of profiles and stable operation. It is suitable for the production of all aluminum doors and windows.

Pneumatic compression in the vertical direction can easily adjust the position. It is suitable for any series of profiles and greatly improves the flatness of the group angle.

The foot switch control can step-by-step control the positioning and grouping of the inclination angle.

The standard set includes three corner knives of different thickness, which can be combined as desired and are suitable for different profiles. (The knife can be adjusted depending on the profile)

LZJ03-130. Angle crimping press for aluminum profiles, suitable for all kinds of aluminum alloy doors and windows, including thermal break profiles and ordinary aluminum profiles

Main Features

Universal corner crimping machine for aluminum profiles. The hydraulic system has the advantages of high power, wide range of profiles and stable operation. It is suitable for the production of all aluminum doors and windows.

Pneumatic compression in the vertical direction can easily adjust the position. It is suitable for any series of profiles and greatly improves the flatness of the group angle.

The foot switch control can step-by-step control the positioning and grouping of the inclination angle.

The standard set includes three corner knives of different thickness, which can be combined as desired and are suitable for different profiles. (The knife can be adjusted depending on the profile)

$6,100.00

FENSTEK TEM-200 Automatic Milling Machine

TEM200 Twin Head End Milling Machine For PVC Window Processing

Feature:

1. End milling machine TEM200 is used for milling the transom and door frames in UPVC and aluminum profile.

2. Two motors are connected with two shafts directly.

3. Milling several pcs profile in one cycle.

4. Milling cutter up and down adjustment as well as left and right adjustment for various section of profile .

5. Big diameter for milling cutter, high cutting speed.

6. Cutter spindle connected by shaft coupling, cutter working precision does not effect motor spindle running precision .

Feature:

1. End milling machine TEM200 is used for milling the transom and door frames in UPVC and aluminum profile.

2. Two motors are connected with two shafts directly.

3. Milling several pcs profile in one cycle.

4. Milling cutter up and down adjustment as well as left and right adjustment for various section of profile .

5. Big diameter for milling cutter, high cutting speed.

6. Cutter spindle connected by shaft coupling, cutter working precision does not effect motor spindle running precision .

$7,350.00

FENSTEK LXDB-250 Automatic Milling Machine

LXDB-250 Aluminium window Automatic End Milling Machine

Features:

1.Used for processing aluminum profile end with massive milling.

2.Universal cutter, no need special milling cutter for different profile. Saving cost and cutter replacing time.

3.Super precision main shaft insured accurate and steady processing

4.Hydraulic Feeding device ensure stable feeding..

5.Convenient tool adjustment meets different processing requirements.

Features:

1.Used for processing aluminum profile end with massive milling.

2.Universal cutter, no need special milling cutter for different profile. Saving cost and cutter replacing time.

3.Super precision main shaft insured accurate and steady processing

4.Hydraulic Feeding device ensure stable feeding..

5.Convenient tool adjustment meets different processing requirements.

$24,200.00

SINON LSKC03-100 UPVC Lock Hole Drilling Machine

SINON LSKC03-100 UPVC Lock Hole Drilling Machine

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.2. For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

Main Features

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.

2.For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

3. Horizontal triple heads drilling and vertical copy router with special cutout working table to realize one time finishing.

4.Lock hole Triple heads are behind of the machine bed.

5.Easy adjustment of the height of the triple drill head

6.Adopts gas-liquid damping automatic feeding for Triple drilling heads, reducing the labor intensity of workers.

7. Routing to stops or universal template in 1:1 ratio.

8. Pneumatic horizontal clamping.

9. Equipped with standard hole template. Plain template is standard equipped or specific designed.

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.2. For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

Main Features

1. Hydro-pneumatic actuator cylinder feeding device of the drill system to reduce labor intensity.

2.For milling handle hole, Euro groove slot and various hole or slot of the PVC window profile.

3. Horizontal triple heads drilling and vertical copy router with special cutout working table to realize one time finishing.

4.Lock hole Triple heads are behind of the machine bed.

5.Easy adjustment of the height of the triple drill head

6.Adopts gas-liquid damping automatic feeding for Triple drilling heads, reducing the labor intensity of workers.

7. Routing to stops or universal template in 1:1 ratio.

8. Pneumatic horizontal clamping.

9. Equipped with standard hole template. Plain template is standard equipped or specific designed.

$4,900.00

FENSTEK MHD-4-5000 Industrial Multi-Drilling Machine

MHD4-5000 Multi-drilling Machine For PVC Window Processing

Feature:

1. UPVC window drilling machine is used for drilling holes for PVC profiles, and mounting holes for window and doors installation.

2. Multi-drilling head can be added to meet multi-group holes processing in one time.

3. Hydraulic cylinders to ensure steady feeding.

4. PLC control, each machine head can works individual and combination.

Feature:

1. UPVC window drilling machine is used for drilling holes for PVC profiles, and mounting holes for window and doors installation.

2. Multi-drilling head can be added to meet multi-group holes processing in one time.

3. Hydraulic cylinders to ensure steady feeding.

4. PLC control, each machine head can works individual and combination.

$21,500.00

FENSTEK TAWSM3 Automatic Industrial Water Slot Milling Machine

TAWSM3 UPVC Window Double Head Water Slot Milling Machine

Feature:

1. UPVC water slot milling machine mainly used for milling all kinds of water slots and air pressure balance grooves.

2. Two groups of three-axis milling heads along guide, with high precise processing and high production efficiency.

3. The length of milling water slot within 60mm is adjustable and use widely.

4. Absolute milling feeding without professional maintenance and high quality.

5. Apply to high grade and mass windows production.

Feature:

1. UPVC water slot milling machine mainly used for milling all kinds of water slots and air pressure balance grooves.

2. Two groups of three-axis milling heads along guide, with high precise processing and high production efficiency.

3. The length of milling water slot within 60mm is adjustable and use widely.

4. Absolute milling feeding without professional maintenance and high quality.

5. Apply to high grade and mass windows production.

$18,500.00

SINON SSJ06-450 Single Head Saw

SINGLE-HEAD FRONT SAW SINON SSJ06-450

Single-head front saw for cutting aluminum and PVC profiles -45, 90, +45 degrees.

450 mm saw blade ● Suitable for cutting PVC and aluminum profiles. ● Angle range: 45°, 90°, 135°, the angle of rotation is adjusted manually. ● The saw blade rotates smoothly thanks to the high-precision main spindle box, ensuring stable operation with high precision

Single-head front saw for cutting aluminum and PVC profiles -45, 90, +45 degrees.

450 mm saw blade ● Suitable for cutting PVC and aluminum profiles. ● Angle range: 45°, 90°, 135°, the angle of rotation is adjusted manually. ● The saw blade rotates smoothly thanks to the high-precision main spindle box, ensuring stable operation with high precision

$4,000.00

SINON LJZ2F-500 Single Head Saw

SINGLE-HEAD BOTTOM FEED SAW

LJZ2F-500 Single-head bottom feed saw for cutting aluminum at various angles. 500mm saw blade. Cutting range 25-155 degrees

MAIN FEATURES

Suitable for door and window profiles, LED lamp frame profiles, curtain wall profiles, etc. Cutting aluminum and PVC profiles. Cutting angle: 25 ° - 155 ° Equipped with a saw blade with a diameter of 500 mm. Equipped with a 3.5m long calibration table and a 4m high profile table. Equipped with a cutting protective screen that automatically lowers when cutting to prevent metal chips from splashing. Horizontal and vertical clamping devices, stable cutting. High precision, high cutting stability, good appearance of the whole machine

LJZ2F-500 Single-head bottom feed saw for cutting aluminum at various angles. 500mm saw blade. Cutting range 25-155 degrees

MAIN FEATURES

Suitable for door and window profiles, LED lamp frame profiles, curtain wall profiles, etc. Cutting aluminum and PVC profiles. Cutting angle: 25 ° - 155 ° Equipped with a saw blade with a diameter of 500 mm. Equipped with a 3.5m long calibration table and a 4m high profile table. Equipped with a cutting protective screen that automatically lowers when cutting to prevent metal chips from splashing. Horizontal and vertical clamping devices, stable cutting. High precision, high cutting stability, good appearance of the whole machine

$9,350.00

SINON LJZ2F-600 Single Head Saw

SINGLE-HEAD SAW WITH BOTTOM FEED SINON LJZ2F-600, 600 MM DISC

JZ2F-600 Automatic single-head saw with bottom feed. Cutting aluminum door and window profiles at an angle of 15-165 degrees. Saw blade diameter 600 mm

Features

1. This automatic single head aluminum profile cutting machine mainly used for cutting aluminum and PVC profiles, with bottom-up saw blade feeding type.

2. This machine is suitable for cutting industrial aluminum and facade profiles, aluminum doors and windows.

3. Equipped with feeding and measuring roller table.

4. The working table is adjustable to increase the cutting area.

JZ2F-600 Automatic single-head saw with bottom feed. Cutting aluminum door and window profiles at an angle of 15-165 degrees. Saw blade diameter 600 mm

Features

1. This automatic single head aluminum profile cutting machine mainly used for cutting aluminum and PVC profiles, with bottom-up saw blade feeding type.

2. This machine is suitable for cutting industrial aluminum and facade profiles, aluminum doors and windows.

3. Equipped with feeding and measuring roller table.

4. The working table is adjustable to increase the cutting area.

$10,650.00

SINON Thermal Break Aluminium Assembly Machines Set (non CNC)

Thermal Break Assembly Machine

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of knurling machine with strip feeder device

1 set of rolling machine

Daily capacity is 5~6 Tons per 10 hours

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of knurling machine with strip feeder device

1 set of rolling machine

Daily capacity is 5~6 Tons per 10 hours

$25,800.00

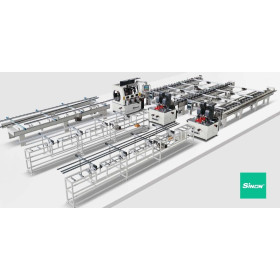

SINON Thermal Break Aluminium Assembly Machines Set (CNC)

Thermal Break Assembly Machine

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of CNC knurling machine with strip feeder device

1 set of CNC rolling machine

Daily capacity is 5~6 Tons per 10 hours

Thermal break assembly machine is used for producing thermal break aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine.

Thermal Break Machine Introduction:

Thermal break machine is used for producing thermal barrier aluminum profiles, including two machines: knurling machine with plastic strip inserter, rolling machine. The finished product as follows:

Two pieces of aluminum profiles are connected just by polyamide strip. Aluminum can transfer heat or cold very easily, its thermal conductivity is high. But polyamide strip’s thermal conductivity is very low, then can block the heat or cold transferring through aluminum.

Raw material of polyamide strip is 75% nylon and 25% glass-fiber, we call PA66 GF25 or polyamide

Consist of

1 set of CNC knurling machine with strip feeder device

1 set of CNC rolling machine

Daily capacity is 5~6 Tons per 10 hours

$67,500.00

FENSTEK HTW2-120 Double Head Welding Machine UPVC

FENSTEK HTW2-120

DOUBLE-HEAD WELDING MACHINE

Features

1. The double-head welding machine for UPVC windows is the most popular type of equipment with 2mm welding.

2. The guide with insert is used.

3. The last head of the machine can weld at different angles from 30 to 180 degrees.

4. The solid base and structure of the machine ensure a long service life with high dimensional accuracy.

5. The profile fastener ordered separately can meet the processing requirements of profiles of different heights.

6. The special profile fastener is easy to replace, which ensures high strength of the angle and good cleaning afterwards.

7. Each head of the machine can work separately or in combination

DOUBLE-HEAD WELDING MACHINE

Features

1. The double-head welding machine for UPVC windows is the most popular type of equipment with 2mm welding.

2. The guide with insert is used.

3. The last head of the machine can weld at different angles from 30 to 180 degrees.

4. The solid base and structure of the machine ensure a long service life with high dimensional accuracy.

5. The profile fastener ordered separately can meet the processing requirements of profiles of different heights.

6. The special profile fastener is easy to replace, which ensures high strength of the angle and good cleaning afterwards.

7. Each head of the machine can work separately or in combination

$14,500.00

FENSTEK HW2S260 Double Head Welding Machine UPVC

HW2S260 Double Head Welding Machine for Laminated Profile Welding

FEATURES

1. The double head welding machine for PVC window is specially designed for welding PVC laminated window profile with 0.2mm welding result.

2. High efficiency of welding and surface cleaning in one machine.

3. Manual adjustment can also realize 2mm welding.

4. Unique maximum welding height of 260mm.

5. All movement systems adopt high-precision square bearings.

6. Pneumatic braking device.

7. Solid base and machine structure ensure long service life with high precision.

8. Profile clamp ordered separately can meet the processing requirements of various profiles

FEATURES

1. The double head welding machine for PVC window is specially designed for welding PVC laminated window profile with 0.2mm welding result.

2. High efficiency of welding and surface cleaning in one machine.

3. Manual adjustment can also realize 2mm welding.

4. Unique maximum welding height of 260mm.

5. All movement systems adopt high-precision square bearings.

6. Pneumatic braking device.

7. Solid base and machine structure ensure long service life with high precision.

8. Profile clamp ordered separately can meet the processing requirements of various profiles

$28,500.00

FENSTEK SH-02 Single Head Welding Machine UPVC

FENSTEK SH-02 SINGLE-HEAD WELDING MACHINE

Features:

1. Single-head welding machine for UPVC windows is specially designed for welding at 90 degrees.

2. It can also weld at different angles between 0 and 180 degrees.

3. PLC-controlled machine operation.

4. Control of two separate clamping devices for easy operation.

5. It can weld white profile (2mm) and color profile (0.2mm). Mode switching is automatic, from the computer.

Features:

1. Single-head welding machine for UPVC windows is specially designed for welding at 90 degrees.

2. It can also weld at different angles between 0 and 180 degrees.

3. PLC-controlled machine operation.

4. Control of two separate clamping devices for easy operation.

5. It can weld white profile (2mm) and color profile (0.2mm). Mode switching is automatic, from the computer.

$10,000.00

FENSTEK ADDSE Single Head Industrial Screw Driver

ADSSE Auto Screw Driver Machine for UPVC Window Features:

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

1. Auto Screw Driver Machine is a stationary Screwdriver. Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e. g. to fix the reinforcement in UPVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate. 4. High Efficiency: Screw driving cycle time to insert one self-drilling screw (3,9 x 19mm) for reinforcement fixing approx. 2 seconds.

5. Stable: Feed capacity 30 or 80 screws per minute depending on dimension of screw

$6,300.00

FENSTEK ADDSE-2

ADSSE2 UPVC Window & Door Auto Screw Driver Machine Feature:

1. Auto screw driver machine ADSSE2 is a stationary Screwdriver Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e.g.to fix the reinforcement in PVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate.

4. Constant screw driving depth for all materials and independent lf the work piece height due to the automatic depth of drive control.

5. Simple Operation: Manual operation by treadle

6. High Efficiency: Screw driving cycle time to insert one self-drillng screw for reinforcement fixing approx.2 seconds.

7. Horizontal clamping device.

1. Auto screw driver machine ADSSE2 is a stationary Screwdriver Advancing Unit with integrated Screw Feeder to insert screws into wood, plastics or metal, e.g.to fix the reinforcement in PVC profiles.

2. Automatic: Integrated screw feeding system and automatic start of the hopper movement when operating.

3. Flexible Production: Work piece height (screwing level) can vary between 35 and 95 mm above the base plate.

4. Constant screw driving depth for all materials and independent lf the work piece height due to the automatic depth of drive control.

5. Simple Operation: Manual operation by treadle

6. High Efficiency: Screw driving cycle time to insert one self-drillng screw for reinforcement fixing approx.2 seconds.

7. Horizontal clamping device.

$11,250.00

FENSTEK ASD-6000 Industrial Screw Driver with Drilling Option

ASD-6000

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

UPVC Window CNC Screwing Drilling Machine

Features:

1. This auto screw driver machine mainly used for inserting screws to mental profile to fix the reinforcement in upvc profile, and drilling installed holes.

2. Inserting and drilling in one machine. The screw spacing and mounting hole position are evenly distributed automatically

3. Machine head is imported from Germany POWERSURT. High reliability.

4. Imported rack and pinion drive, fast speed and high precision.

5. Two separate working areas, each work area can be placed 4 pcs as client requirement, and the discharge is not stopped.

6. Schneider controlling system based on the windows 7 system. It can be linked with ERP software to data sharing and communication.

7. light curtain can be included as client requirement.

8. Fixture will be probably required as client requirement.

$81,700.00

SINON XNSHM01

SINON XNSHM01 PVC SASH ASSEMBLY STATION

This sash hardware installation table is mainly used for the quick assembly of door and window hardware. The automatic window frame centering mechanism and up and down adjustment mechanism make the assembly simple and fast, and greatly improve the work efficiency

This sash hardware installation table is mainly used for the quick assembly of door and window hardware. The automatic window frame centering mechanism and up and down adjustment mechanism make the assembly simple and fast, and greatly improve the work efficiency

$23,600.00