YILMAZ MACHINE UPVC & ALUM

There are 7 products.

YILMAZ ALM 6510 Cutting&Milling Center Aluminium

ALM 6510 is 8-axis CNC controlled machining center which is specifically designed to process any kind of aluminium profiles in the market. The machine can do all operations on four sides of aluminium profiles such as milling, opening key holes, hinge holes, handle holes, marking, saw blade cutting etc. ALM 6510 has the programming feature which provides minimum waste and maximum amount of production. 7 pieces of aluminium profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. The cutting unit can perform serial cutting of profiles in the range of 45⁰-135°. Operator attaches barcodes on the processed profiles to make them ready for crimping operation.

$0.00

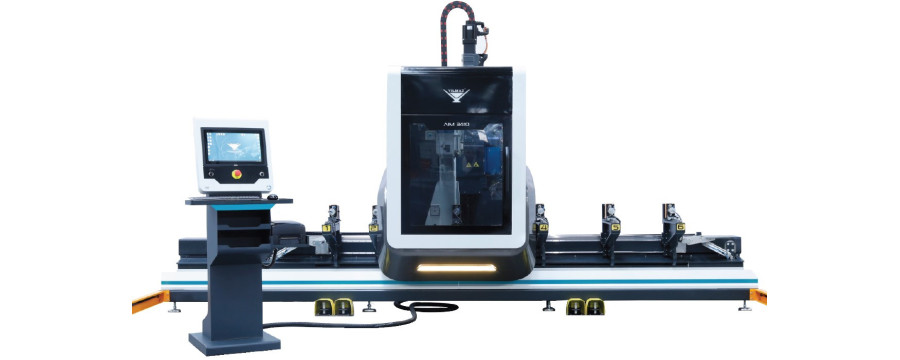

YILMAZ AIM 3410 4-Axis Machining Center

AIM 3410 is a 4-axis CNC machine designed specifically for processing all types of aluminum and PVC profiles, low carbon alloys and thin-walled steel profiles available in the market. Thanks to the 4th axis function, it can also machine 3 profile surfaces. Quick tool changes are ensured by a mobile in-line magazine equipped with 8 standard tools. To minimize tool change time, the tool magazine was designed on the moving Y axis of the machine.

$0.00

YILMAZ AIM 7510 CNC Machining Center 5-Axis

AIM 7510 is 5-axis servo-controlled machining center which is designed to perform drilling, grooving, notching, taping, saw milling, etc. on all kinds of aluminium & PVC profiles, light alloys in general and thin walled steel profiles.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

With the fully automatic machining function of this machine, 5 surfaces of profiles can be processed efficiently and economically. Fast tool change is ensured by the movable and chain tool magazine equipped with 12 standard tools. The tool magazine is mounted on the movable machining head to minimize tool change time. With a 350 mm diameter saw blade, the machine provides flexible processing, especially when performing outdoor work.

$0.00

YILMAZ AIM 4420 / 7420 CNC Machining Center 4-Axis

YILMAZ AIM 4420 / 7420 4-AXIS MACHINING CENTER FOR ALUMINUM PROFILES

AIM 4420-7420 is a 4-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles, as well as low-carbon, thin-walled steel profiles used in the market. AIM 4420 : 4 m. - AIM 7420: 7 m.

PRICE ON REQUEST

AIM 4420-7420 is a 4-axis CNC machine specially designed for milling, drilling, tapping and cutting all kinds of aluminum profiles, as well as low-carbon, thin-walled steel profiles used in the market. AIM 4420 : 4 m. - AIM 7420: 7 m.

PRICE ON REQUEST

$0.00

YILMAZ PIM6509 CNC Cutting&Machining Center UPVC

PIM 6509 - PVC CUTTING AND PROCESSING CENTER FOR 250 WINDOWS IN 8 HOURS SHIFT

PIM 6509 is 8-axis CNC controlled machining center which is specifically designed to process any kind of PVC profiles in the market. The machine can do all operations on four sides of PVC profiles such as milling, opening key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc. PIM 6509 has the programming feature which provides minimum waste and maximum amount of production. 7 pieces of PVC profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. Operator attaches barcodes on the processed profiles to make them ready for welding operation.

PIM 6509 is 8-axis CNC controlled machining center which is specifically designed to process any kind of PVC profiles in the market. The machine can do all operations on four sides of PVC profiles such as milling, opening key holes, water slots, hinge holes, handle holes, marking, saw blade cutting etc. PIM 6509 has the programming feature which provides minimum waste and maximum amount of production. 7 pieces of PVC profiles can be placed on the feeding conveyor of the machine and 3-axis pneumatic gripper moves them into the milling & cutting center for the milling and cutting operations. Operator attaches barcodes on the processed profiles to make them ready for welding operation.

$0.00

YILMAZ CCL 1660 CNC Welding&Corner Cleaning Line UPVC

YILMAZ CCL 1660 AUTOMATIC WELDING AND CLEANING CENTER FOR PVC PROFILES

The automatic line includes a four-head welding unit DK540, a transport table-accumulator for cooling SA250, a rotary robot for the cleaning machine SA260 and an automatic machine for processing the welding seam CNC 610, an option for welding profiles with a seal.

As a result of simultaneous welding of four corners of the PVC profile, the finished frame is fed to the corner cleaning machine for cleaning the surfaces of PVC profiles welded at an angle of 90 ° using a serial robot-automatic system.

The automatic line includes a four-head welding unit DK540, a transport table-accumulator for cooling SA250, a rotary robot for the cleaning machine SA260 and an automatic machine for processing the welding seam CNC 610, an option for welding profiles with a seal.

As a result of simultaneous welding of four corners of the PVC profile, the finished frame is fed to the corner cleaning machine for cleaning the surfaces of PVC profiles welded at an angle of 90 ° using a serial robot-automatic system.

$0.00

YILMAZ PIM6508 CNC Cutting & Milling Center UPVC

YILMAZ PIM6508 PVC PROFILE SAWING AND PROCESSING CENTER

PIM 6508 - PVC CUTTING AND PROCESSING CENTER

The machine is designed for cutting, milling holes of various configurations on the surfaces of PVC profiles, drilling channels and marking using a CNC-controlled motor unit.

Servo control system providing 8-axis movement

o Touch panel screen

o Barcode printer

o Barcode printing on the surface of the last profile

o Possibility of monitoring the operations carried out on the PVC profile on the PC screen, where the process simulation is displayed

o Remote connection and technical support

o 6500 line memory registration

PIM 6508 - PVC CUTTING AND PROCESSING CENTER

The machine is designed for cutting, milling holes of various configurations on the surfaces of PVC profiles, drilling channels and marking using a CNC-controlled motor unit.

Servo control system providing 8-axis movement

o Touch panel screen

o Barcode printer

o Barcode printing on the surface of the last profile

o Possibility of monitoring the operations carried out on the PVC profile on the PC screen, where the process simulation is displayed

o Remote connection and technical support

o 6500 line memory registration

$0.00