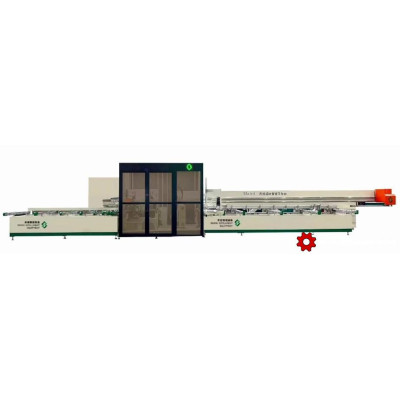

SINON SZA-610 Cutting&Milling Center Aluminium

Aluminium Profile Cutting And Machining Center

Model: SZA610

Input Voltage: 380V/50Hz/3P or Customized

Total power: 45.55KW

Saw blade specifications:∮550*4.4*∮30*120

Sawing angle +45º 90°-45°

Sectional size of sawed profile (width×height):180*150mm

Weight about 12T

Delivery throughout Russia - by transport company.

This is a CNC aluminum profile cutting and machining center that integrates ERP door and window software + 3-angle efficient sawing + 3-station/ 4-direction/ 8-axis drilling and milling + laser scribing.

The profile raw materials are put into the circulator for intelligent clamping, which can realize angle cutting, drilling and milling of glue injection holes, corner code holes, pin holes, drainage holes, lock box holes, center column lines, drive chamfering, corner protection cutting, etc. .

Once clamped, no turnover or sorting is required. After all processing is completed, it directly enters the assembly process.

The equipment occupies a small area, has low requirements on operators, and has fast processing time. It is a core competitive product for mass production of doors and windows, making door and window processing easier.

Suitable for processing door and window profiles with aluminum profiles no larger than 180MM in width and 150MM in height.

1. The CNC aluminum profile cutting and machining center is composed of 8 major modules: loading and conveying module, feeding module, sawing module, drilling and milling module, laser marking module, discharging module, discharging output module and automatic labeling module, thereby realizing manual loading of finished materials One-time clamping, no turnover, no sorting, all flexible automatic composite processing operations.

2. After simple system settings, the system can directly process automatically according to the data optimized by the software. Customers can also import the profile processing data optimized by the door and window optimization software into the operation and system using a USB disk or network (need to communicate with the software manufacturer in advance data structure).

3. This model adopts imported control system and bus absolute value servo controller. The whole machine shares 16 CNC axes, 10 axes of frequency conversion, and multi-level pressing and material support are realized by CNA communication, frequency converter, driver bus and PC program control respectively. Transmitting data is stable and fast.

4. The human-machine interface of the industrial control computer is more convenient for the operator to use, and it is more convenient to switch the function selection, parameter adjustment and troubleshooting of the cutting saw.

5. Equipped with an automatic barcode printer to print material identification in real time, the process information can be identified to facilitate material management.